Biax full-automatic coiling machine

A fully automatic winding machine and moving mechanism technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc. The effect of upgrading and technological progress is good, reducing the occurrence of artificial defective products, and saving production raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

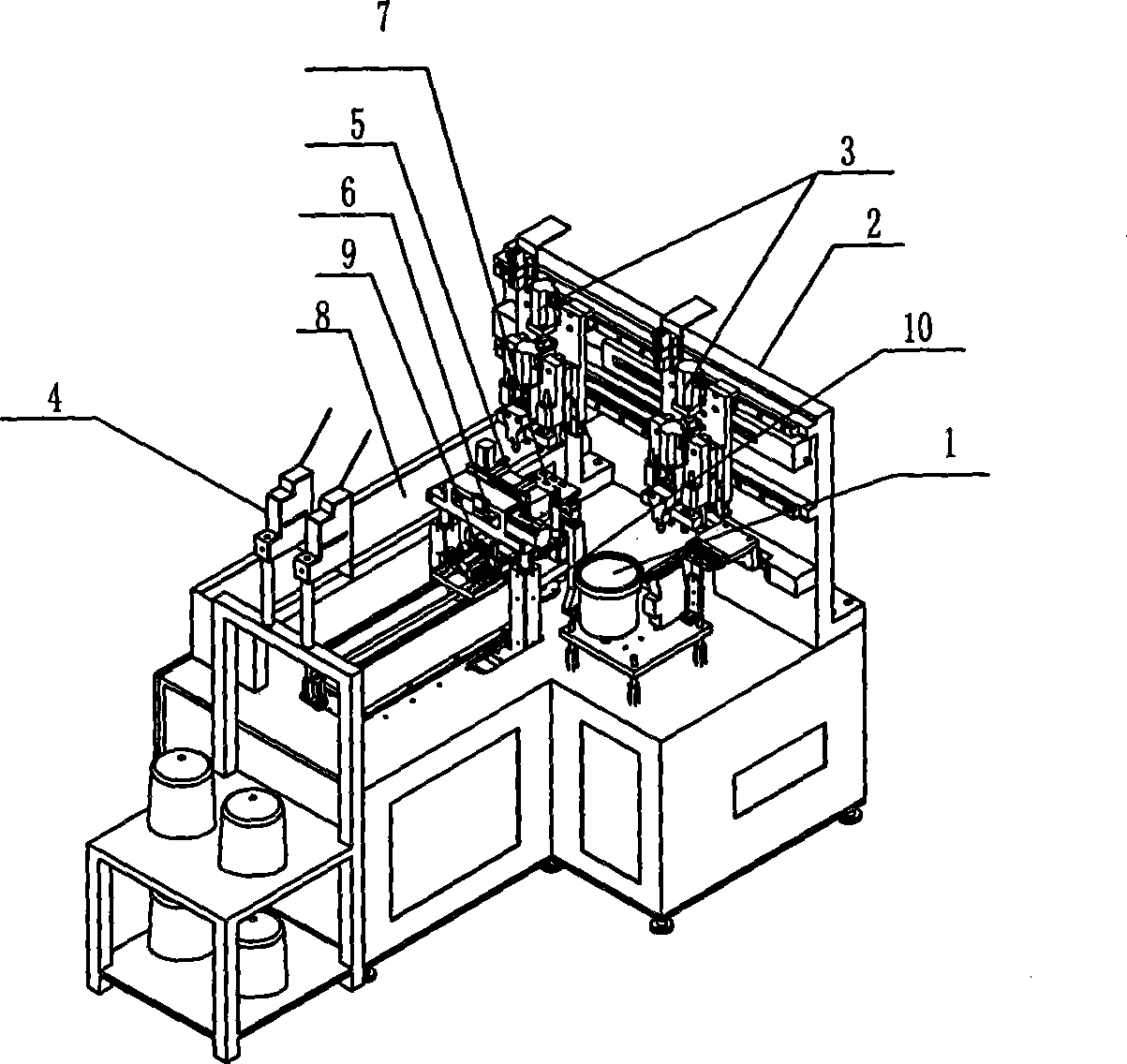

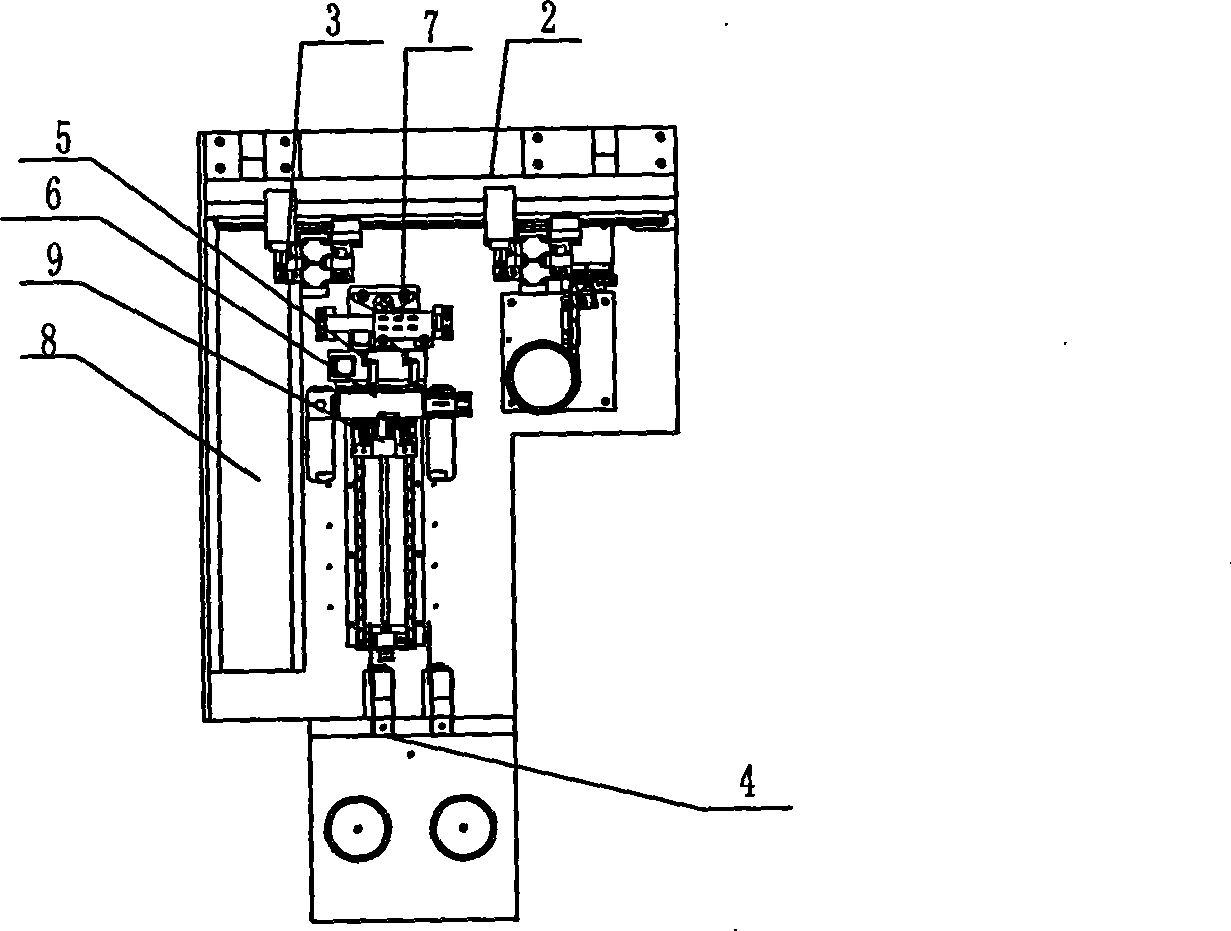

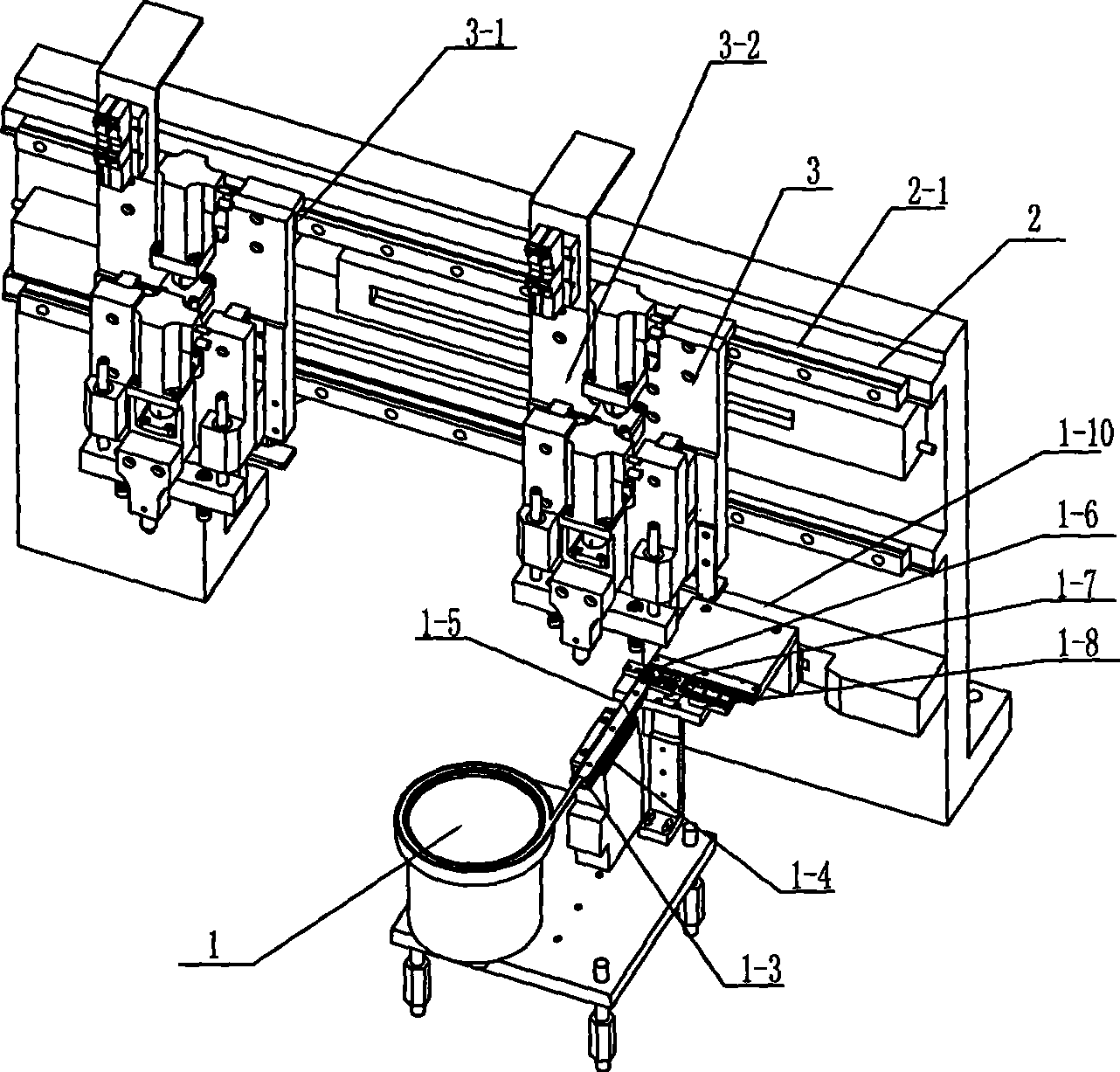

[0044] Such as Figure 1-Figure 15 As shown, the double-axis automatic winding machine of the present invention mainly includes a feeding mechanism 1, a moving mechanism 2, a pick-and-place mechanism 3, a tension control mechanism 4, a wire hanging mechanism 5, and a winding mechanism connected to each other under PLC control. Mechanisms such as wire arrangement mechanism 6, solidification mechanism 7 and delivery mechanism 8; Feeding mechanism 1 is arranged on a corner of the base platform, delivery mechanism 8 is arranged on the base platform on the opposite side of feeding mechanism 1, and moving mechanism 2 is arranged on the machine base. On the right side of the table, the pick-and-place mechanism 3 is connected to the moving mechanism 2, the tension control mechanism 4 is set on the left side of the base platform through a bracket, and the wire hanging, winding and arranging mechanisms (5, 6) are connected to the tension control mechanism 4 Set in the middle of the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com