Presplit blasting method

A technology of pre-splitting blasting and pre-splitting holes, which is applied in the field of pre-splitting blasting to protect the integrity and stability of boundary slope rocks, and can solve problems such as electric shovel over-excavation, high mining intensity in open-pit coal mines, and insufficient side impact of blasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

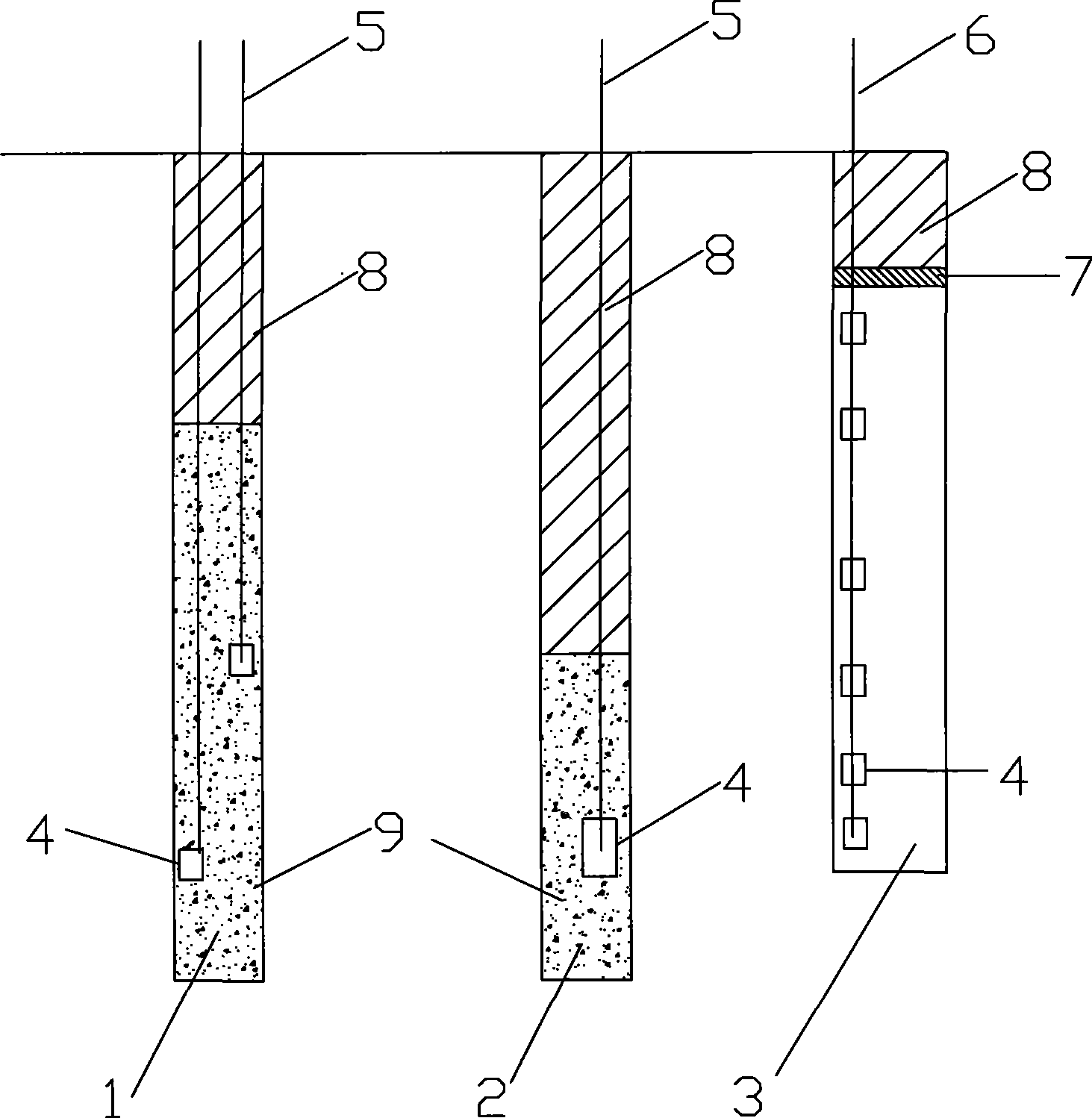

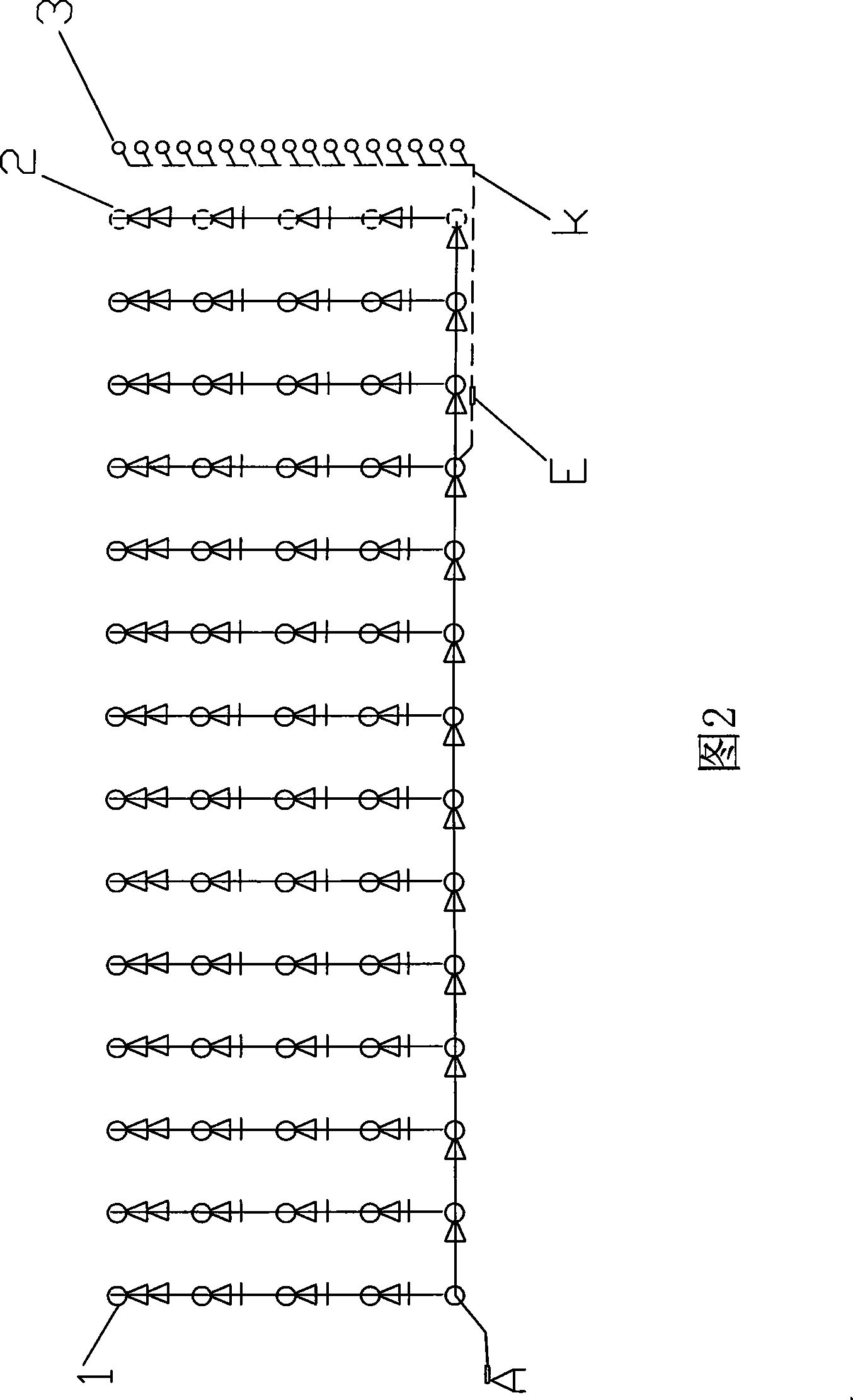

[0019] figure 1 , Fig. 2 has provided the pre-splitting hole of the pre-splitting blasting method of the present invention, the main gun hole and the buffer hole charging structure schematic diagram and the detonation network and the pre-splitting hole, the buffer hole plane position schematic diagram. A row of small-diameter pre-splitting holes 3 is drilled along the designed excavation contour between the mining area and the boundary slope, and a buffer hole 2 is designed between the main gun hole 1 and the pre-splitting hole 3 parallel to the pre-splitting hole 3 . In each pre-splitting hole 3, six priming charges 4 are connected in series through a booster wire 6. The priming charges 4 are arranged on the side of the main gun hole 1, and the upper part is separated by an air spacer 7 and backfilled with rock powder 8. The filling height is 12-20 times the blast hole diameter.

[0020] Ammonium oil explosives 9 are housed in the main gun hole 1, and a pair of nonelectric n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com