On-line film coating environment whole set adjusting device of float glass production line annealing kiln A0 zone

A float glass and regulating device technology, applied in the direction of coating, etc., can solve problems such as difficult control of temperature field, unstable kiln pressure, and turbulent air flow, and achieve the effects of uniform and suitable temperature field, improved product quality, and stable pressure field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

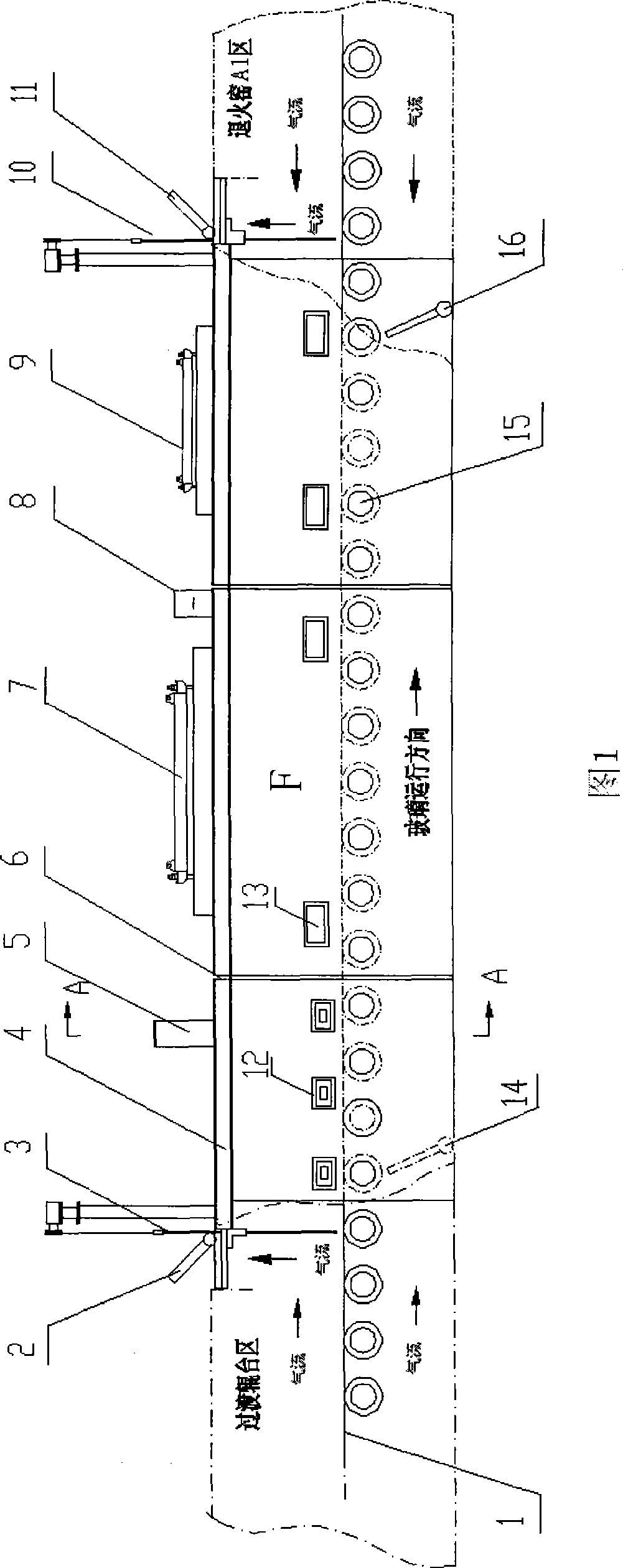

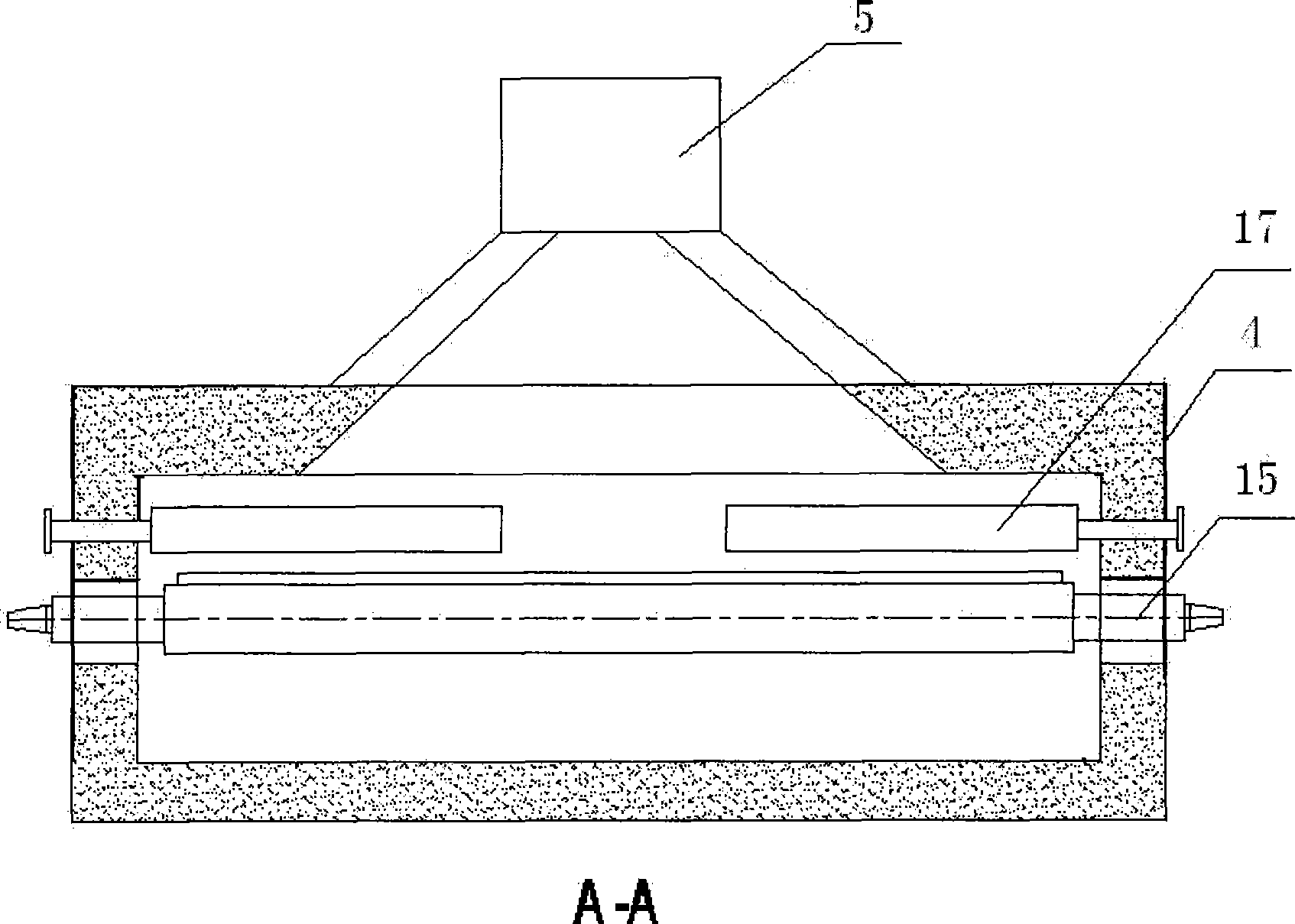

[0009] Referring to Figure 1, figure 2 , a complete set of online coating environment adjustment device in the A0 area of the annealing kiln of the float glass production line, including a shell 4. The shell can be connected in turn by a plurality of interlayer square cylinders as shown in the figure. The interlayer is filled with thermal insulation cotton, and two adjacent Expansion slits 6 are left between the square cylinders, and the expansion slits are filled with thermal insulation cotton for sealing to ensure that the shell is not deformed. The front port of the shell is connected with the transition roller table area of the float glass production line, and the rear port of the shell is connected with the annealing kiln A1 area of the float glass production line, and a carrier glass belt 1 is installed in the shell from the transition roll table area to the annealing kiln. The transmission roller 15 running in the A1 area, the transmission roller 15 traverses both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com