End location self-lying lift hook of lorry-mounted crane

A technology of truck-mounted cranes and hooks, which is applied in the directions of cranes, load hanging components, transportation and packaging, etc. It can solve the problems of interfering with the driver's sight, increasing unsafe factors in operation, and increasing work intensity, so as not to interfere with driving The effect of improving the sight of the operator, facilitating the loading of goods, and increasing the loading space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

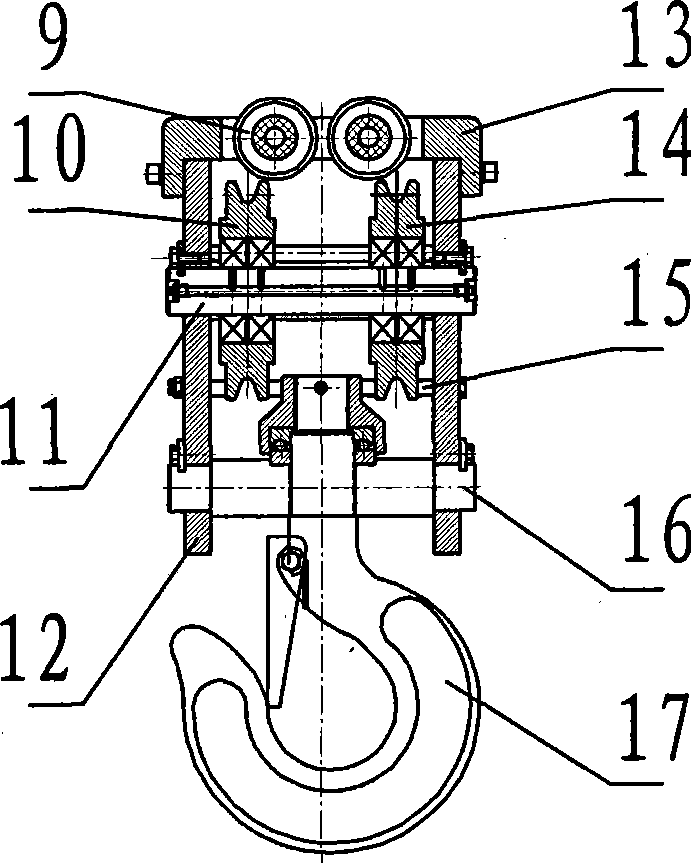

[0011] Embodiment 1: Embodiment 1: The self-lying hook includes the left pulley 3 of the arm head, the right pulley 4 of the arm head, the raised slide rail 5 of the arm head, the steel wire rope 6, the roller assembly 7, the hook assembly 8, The left side pulley 10 of the hook and the right side pulley 14 of the hook are respectively connected with the left side pulley 3 of the arm head and the right side pulley 10 of the arm head on both sides of the raised slide rail 5 of the arm head. The hook assembly 8 is connected with the hook left pulley 10 and the hook right pulley 14 in the hook assembly, and the left pulley 3 of the arm head and the right pulley 4 of the arm head are connected with the left pulley 10 of the hook and the hanger Be connected with wire rope 6 between hook right side pulley 14, arm head left side pulley 3 and arm head right side pulley 4 and suspension hook left side pulley 10 and suspension hook right side pulley 14 are 90 degree arrangement.

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com