Method for structural design of coaxal helicopter composite material blade

A technology of coaxial helicopters and composite materials, applied in the field of helicopter rotor design, can solve the problems such as the lack of details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

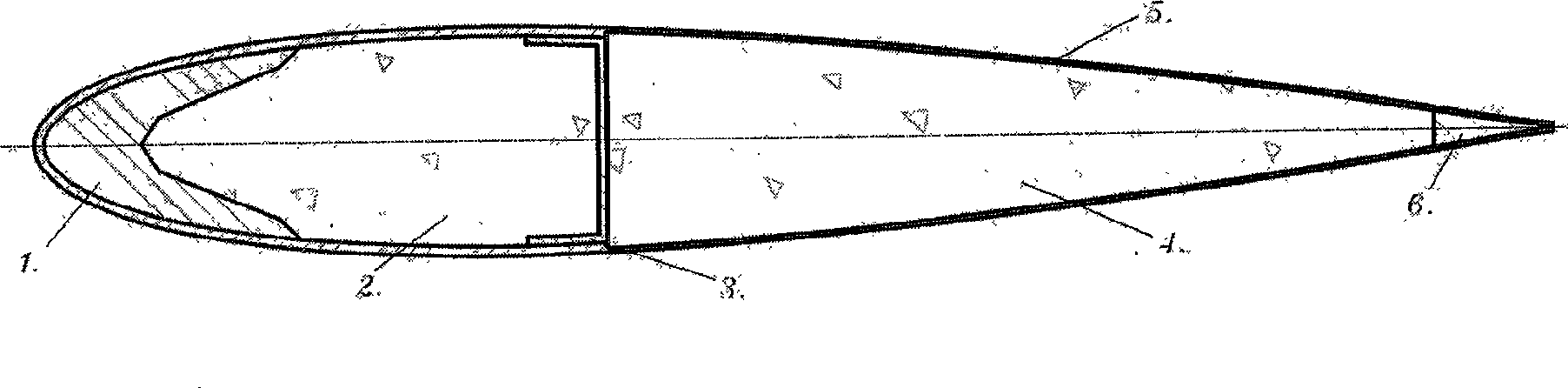

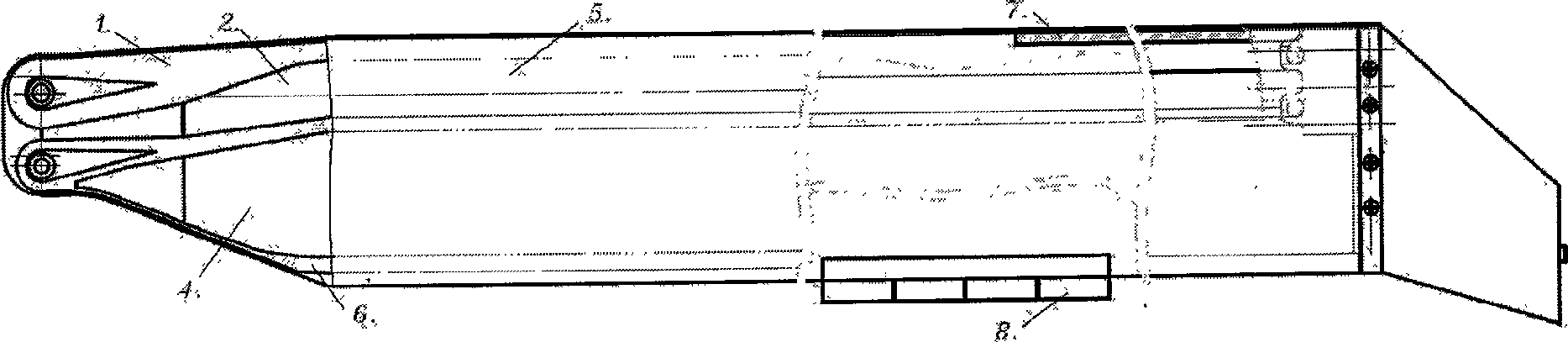

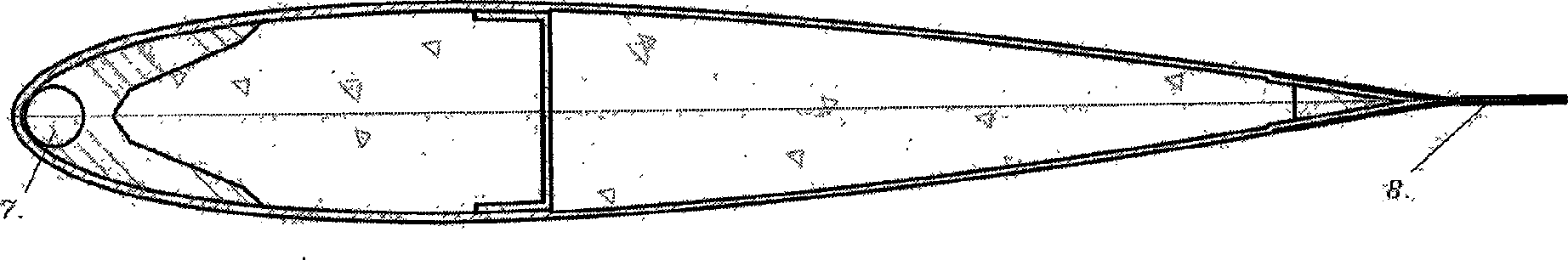

[0048] See figure 1 , figure 2 , image 3 Shown: a method for structural design of a coaxial helicopter composite material blade, the specific steps of the method are as follows (taking a helicopter with a total weight of 350 kg as an example):

[0049] Step 1: Quality Estimation

[0050] The radius of the blade is 2.5m, and the chord length is 0.17m. The mass of the blade can be estimated as:

[0051] m ly =60×2.5×0.172=4.335(kg)

[0052] Step 2: Centrifugal force at the blade root

[0053] The rotor speed is 600 rpm, and the centrifugal force at the blade root can be calculated as:

[0054] f li =0.005483×4.335×2.5×600 2 =21391(N)

[0055] Step 3: (same as above)

[0056] Step 4: Determine the cross-sectional area of the C-beam of the blade

[0057] S c =1.5×21391 / 500=64(mm 2 )

[0058] Step five: (same as the previous section)

[0059] Step 6: (same as above)

[0060] Step 7: Determine the area of the trailing edge of the blade

[0061] It can be prelimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com