Large-scale honeycomb ring spark-erosion grinding machining self-operated measuring device and use method thereof

An automatic measurement and electric spark technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of increased measurement error, pollution measurement, inaccuracy, etc., and achieve the effect of saving time, simplifying processing operations, and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

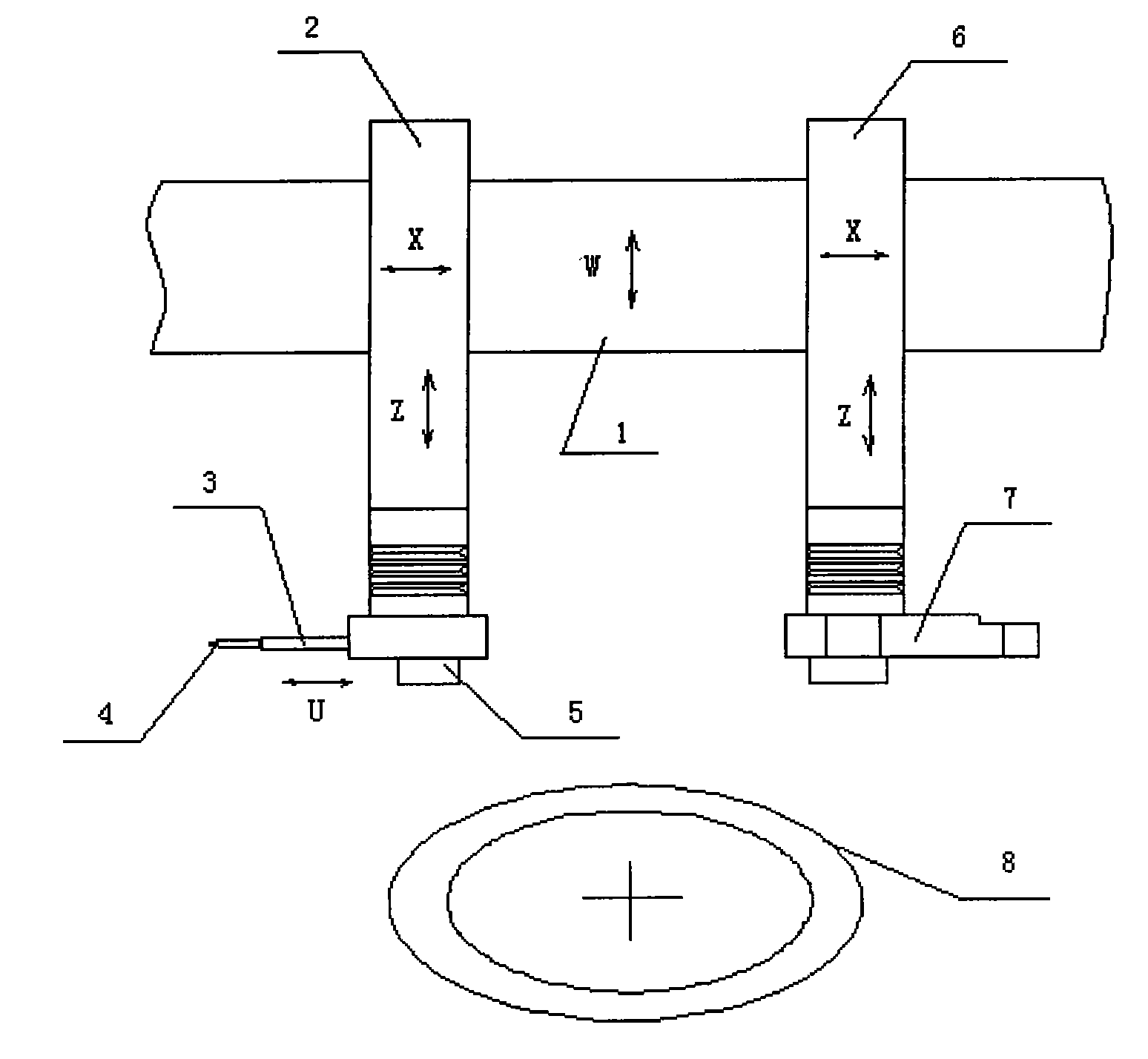

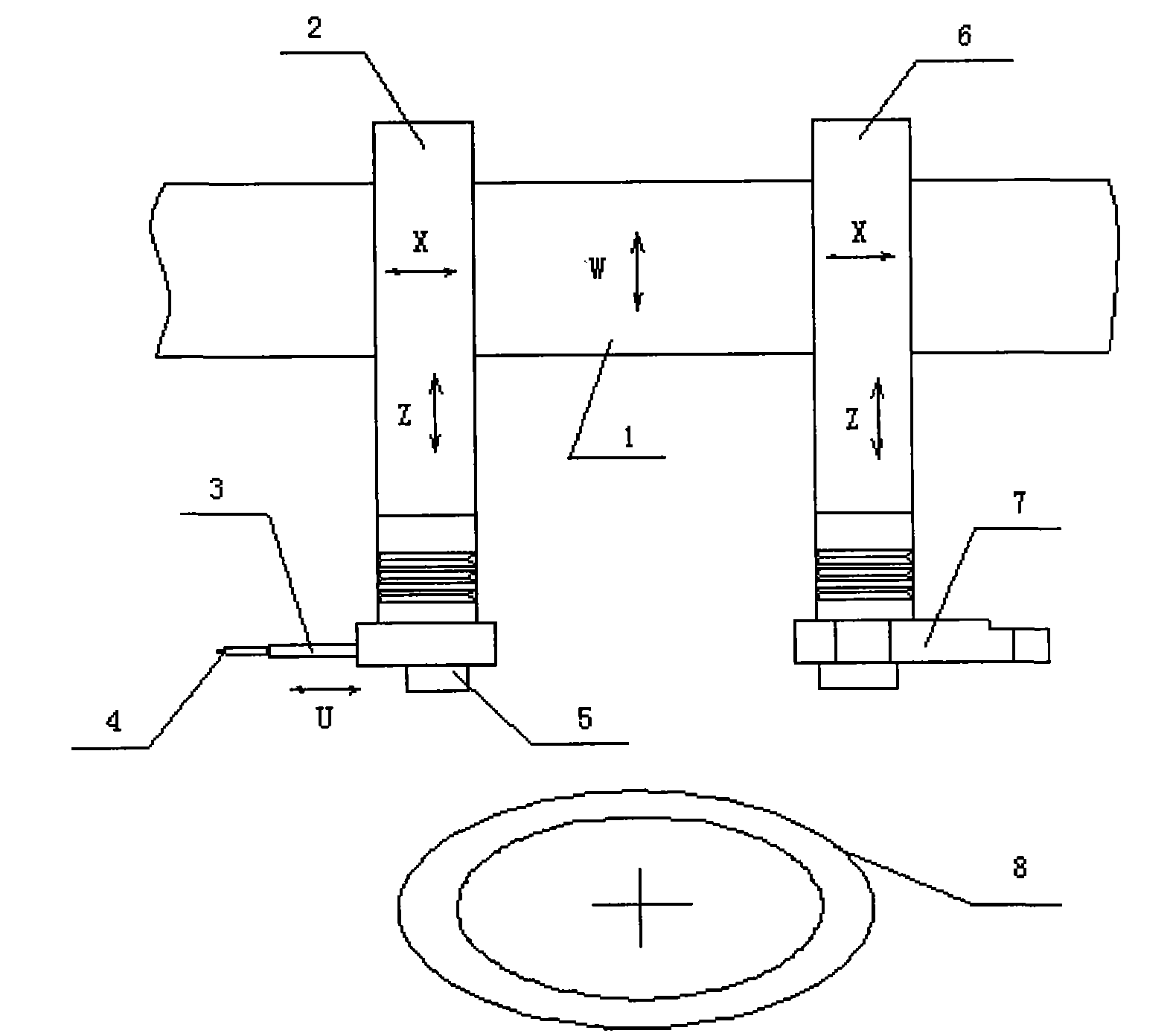

[0013] The device includes an electric spark grinding machine tool, a measuring shaft head 2, a guide rail, an AC servo motor 5, a measuring length gauge 3, and a sensing probe 4, and the measuring shaft head 2 is vertically installed on the left side of the beam 1 of the electric spark grinding machine tool and Parallel to the electrode processing spindle head 6 of the electric discharge grinding machine tool, a guide rail is provided between the measuring spindle head 2 and the beam 1 of the electric discharge grinding machine tool, and the measuring spindle head 2 can be carried out along the beam 1 of the electric discharge grinding machine tool through the guide rail. The horizontal movement of the X axis and the vertical movement of the Z axis along the beam 1 perpendicular to the EDM machine tool, the measuring axis head 2 can drive the Z axis and the U axis to move together when moving in the direction of the X axis, and the measuring axis head 2 is close to the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com