Process for producing green tea

A production process and green tea technology, applied in the field of green tea production technology, can solve the problems of insufficient aroma, high water content, short time, etc., and achieve the effects of clear and lasting aroma, emerald green color, and dark green soup color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below green tea production technology of the present invention is described further.

[0008] This embodiment mainly adds mechanical equipment and new technology on the basis of traditional technology, and its processing technology is as follows:

[0009] Fresh leaves→selection→cooking→kneading→first roasting→wrapping→re-baking→brilliant pot→re-selection→tribute tea.

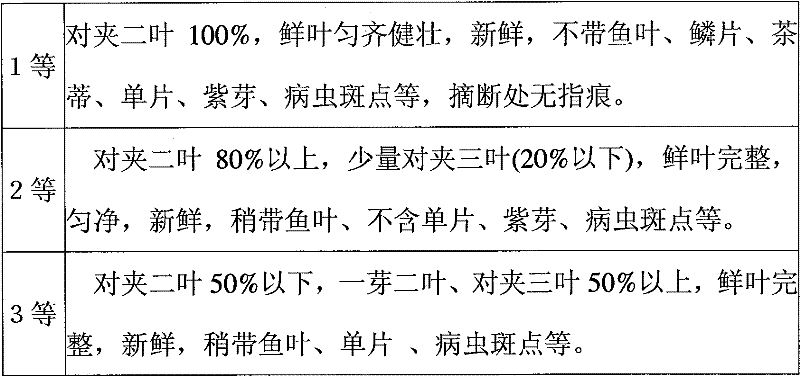

[0010] The basic requirements for the quality of fresh leaves are: to pick fine buds and leaves of tender, fleshy and other varieties. Mainly two pairs of leaves, a small amount of three leaves, the buds and leaves are complete, the color is bright green, fresh and even. The quality of fresh leaves is divided into 3 grades (1-3 etc.), and the standards are shown in the table.

[0011]

[0012]

[0013] In the greening (drying green, cool green, wave green) process, the blue green workshop is required to be clean and hygienic, the room is ventilated, clean, free of peculiar smell, free of foreign d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com