Camera based six degree-of-freedom target measuring and target tracking device with rotatable mirror

A mirror, camera technology, used in measuring devices, re-radiation of electromagnetic waves, radio wave measurement systems, etc., can solve the problems of inaccurate, expensive, and time-consuming repositioning procedures for measuring radial distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

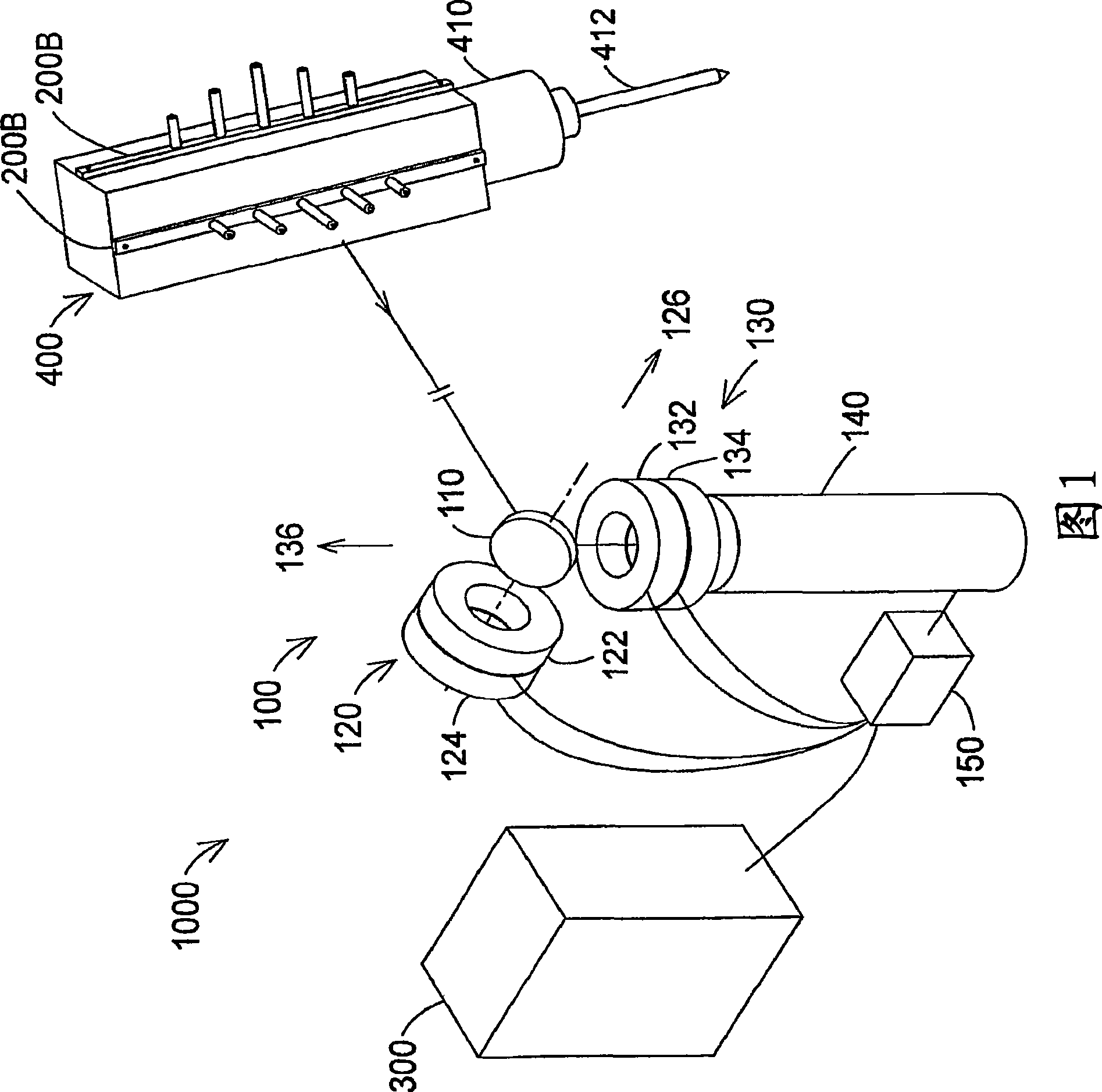

[0028] As shown in FIG. 1 , an exemplary six-degree-of-freedom (6-DOF) tracker 1000 may include a tracking camera arrangement 100 , a target 400 and a computer 300 . Six degrees of freedom may be, for example, x, y, z coordinates of target 400 as well as pitch, roll, and yaw.

[0029] The entire tracking camera device 100 may include a mirror 110 , a first angle component 120 , a second angle component 130 , a camera 140 and a processor 150 .

[0030] The first angle assembly 120 includes a first angle shaft (not shown) on which a goniometer 122 and a motor 124 are mounted. The goniometer 122 is preferably an angle encoder and the motor 124 is preferably a servo motor. A first angular axis (not shown) rotates about a first axis 126, which in this figure is the zenith axis. The first and second axes intersect at a point in space known as the gimbal node.

[0031] The second angle assembly 130 includes a second angle shaft (not shown) on which a goniometer 132 and a motor 134...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com