Flywheel casing on-line rapid assembling device and method

A flywheel housing and fast technology, applied to the frame of the engine, hand-held tools, supporting machines, etc., can solve the problems of low efficiency, difficulty in ensuring the quality of manual assembly, etc., and achieve the effect of ensuring simplicity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

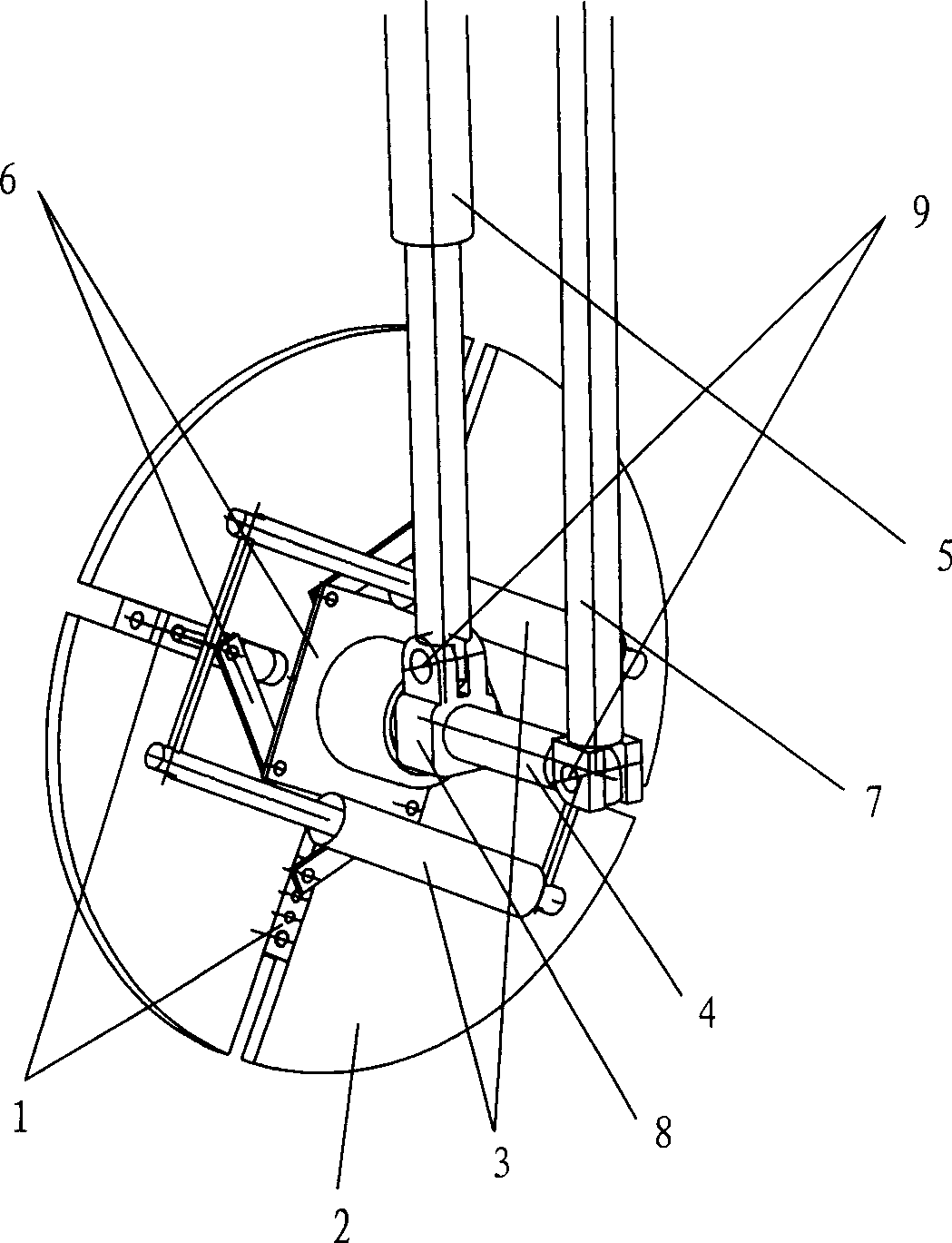

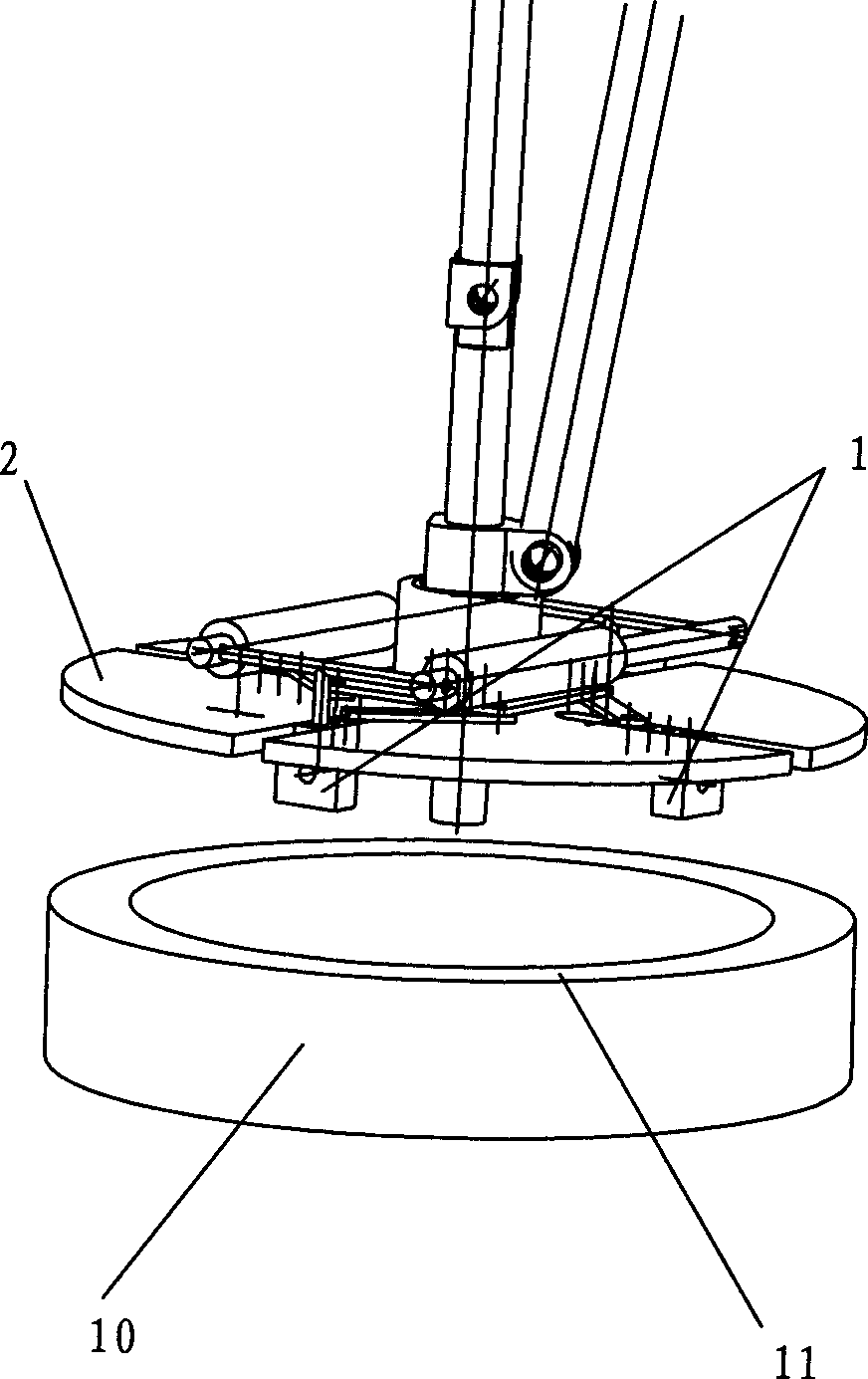

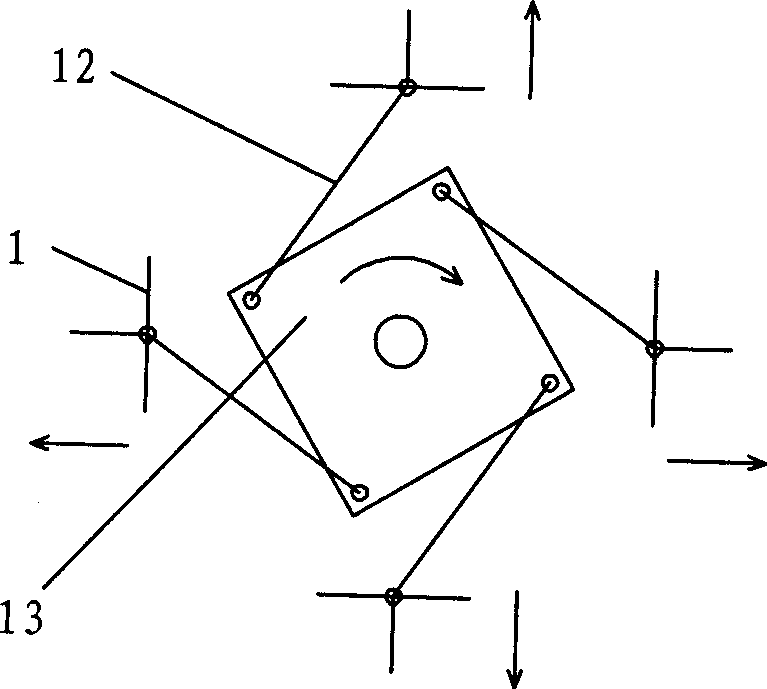

[0023] Such as Figure 1 ~ Figure 5 Shown is a structural diagram of an online quick assembling device for a flywheel shell according to an embodiment of the present invention.

[0024] Such as figure 1 As shown, there is provided an oblique rear view of an assembly system of a flywheel shell online quick assembly device of the present invention, wherein the assembly system includes a clamping mechanism, a rotating mechanism, and a turning mechanism. The clamping mechanism is matched with the flywheel housing and installed on the rotating mechanism, and the turning mechanism is hinged with the rotating mechanism.

[0025] The clamping mechanism includes a chuck 1, a power conversion mechanism 6 and a small air cylinder 3 capable of interlocking with the two. The chuck 1 is installed on the outside of the pressure plate 2, and the small air cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com