Method for preparing high performance flame-retardant terylene inner decoration textile fabric

A flame-retardant polyester and textile technology, which is applied in the field of preparation of high-performance flame-retardant polyester interior textiles, can solve the problems of fabric discoloration, poor durability of flame-retardant effect, serious fabric droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The manufacturing method of high-performance flame-retardant polyester interior textiles is as follows: prepare coating slurry [its components and volume content include: the amount of water-based polyurethane dispersion is 60%, flame retardant (main structure is ) dosage is 30%, SiO 2 Synergist 2.5%, the amount of thickener KF is 7.5%] → coated polyester fabric (gluing amount is 160g / m 2 ) → bake at 150°C for 2 minutes. The flame retardant properties of polyester interior textiles treated by this process are shown in Table 1-3.

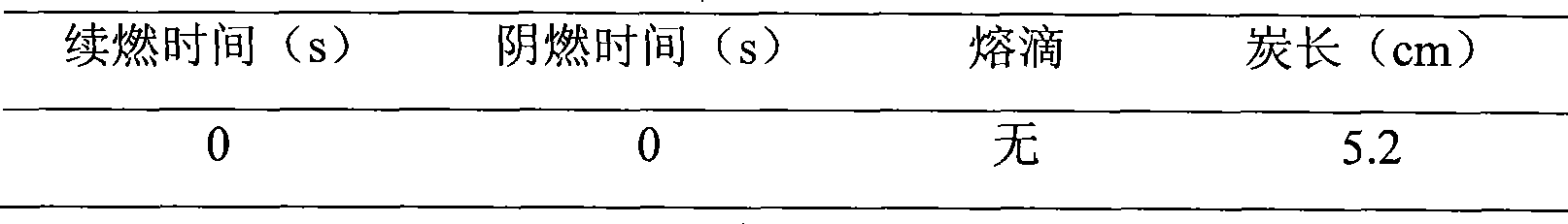

[0020] Table 1 Combustion performance

[0021]

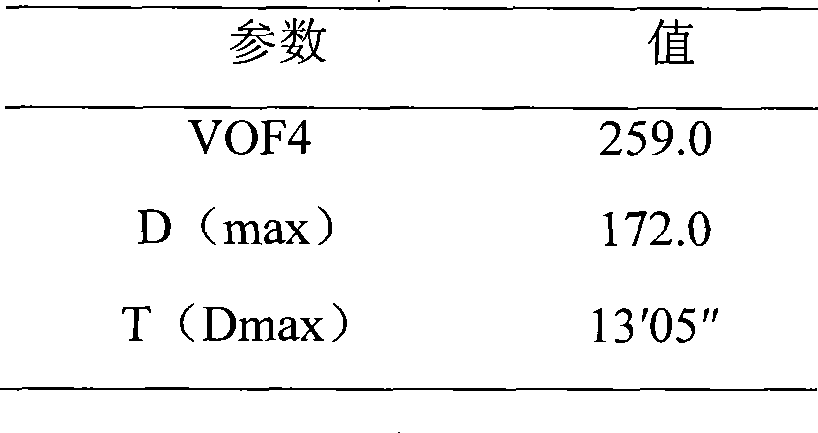

[0022] Table 2 Test data of smoke density experiment

[0023]

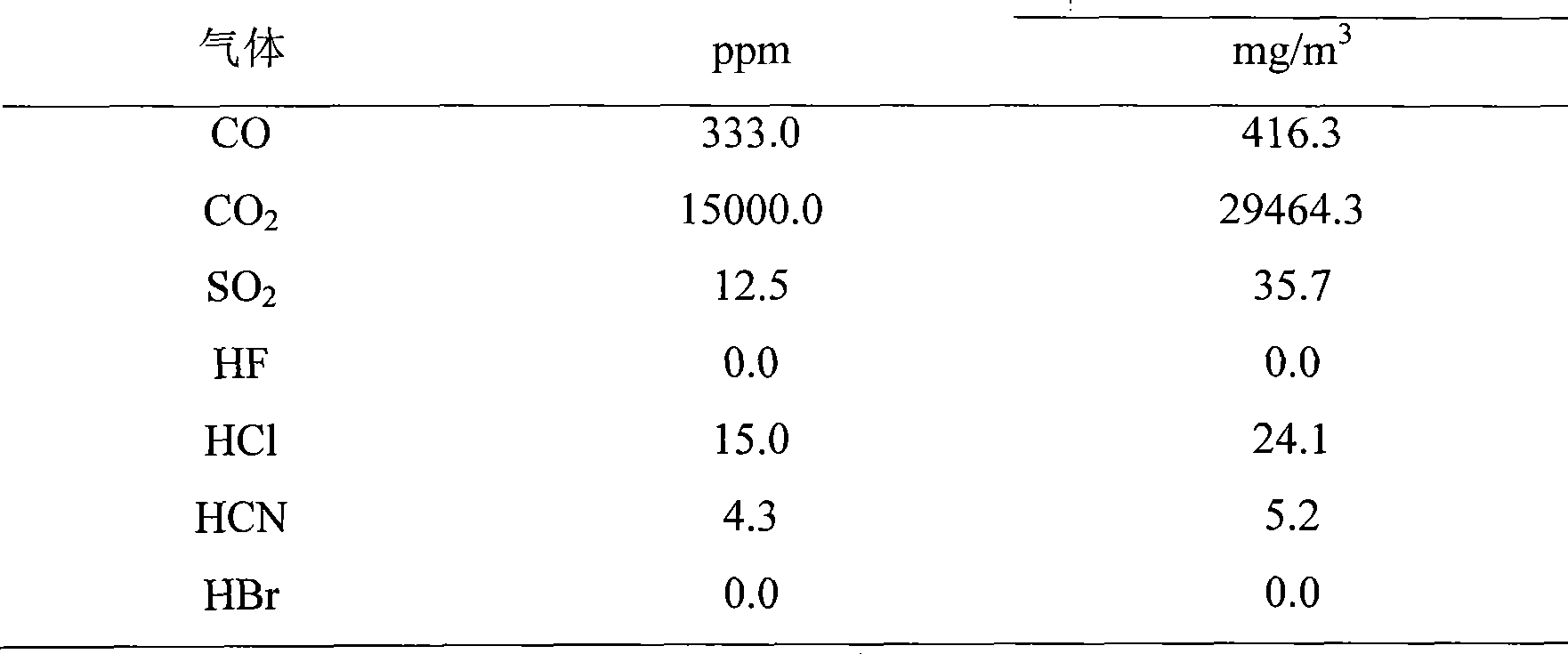

[0024] Table 3 Test data of smoke toxicity experiment

[0025]

Embodiment 2

[0027] The manufacturing method of high-performance flame-retardant polyester interior textiles is: preparing coating slurry [its components and volume content include: the amount of water-based polyurethane dispersion is 65%, flame retardant (main structure is ) dosage is 28%, SiO 2 Synergist 2%, the amount of thickener KF is 5%] → coated polyester fabric (gluing amount is 180g / m 2 ) → bake at 150°C for 2 minutes. The flame retardant properties of polyester interior textiles treated by this process are shown in Table 4-6.

[0028] Table 4 Combustion performance

[0029]

[0030] Table 5 Test data of smoke density experiment

[0031]

[0032] Table 6 Test data of smoke toxicity experiment

[0033]

Embodiment 3

[0035] The manufacturing method of high-performance flame-retardant polyester interior textiles is as follows: prepare coating slurry [its components and volume content include: the amount of water-based polyurethane dispersion is 55%, flame retardant (main structure is ) dosage is 35%, SiO 2 Synergist 2%, the amount of thickener KF is 8%] → coated polyester fabric (gluing amount is 200g / m 2 ) → bake at 150°C for 2 minutes. The flame retardant properties of polyester interior textiles treated by this process are shown in Table 7-9.

[0036] Table 7 Combustion performance

[0037]

[0038] Table 8 Test data of smoke density experiment

[0039]

[0040] Table 9 Test data of smoke toxicity experiment

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com