Integrated recognition method for sintering conditions of cement rotary kiln

A cement rotary kiln and identification method technology, applied in cement production, clinker production, etc., can solve the problems of difficulty in full-dimensional state space pattern recognition, difficulty in automatic identification of working conditions, and inability to directly measure the temperature process parameters of the firing zone online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

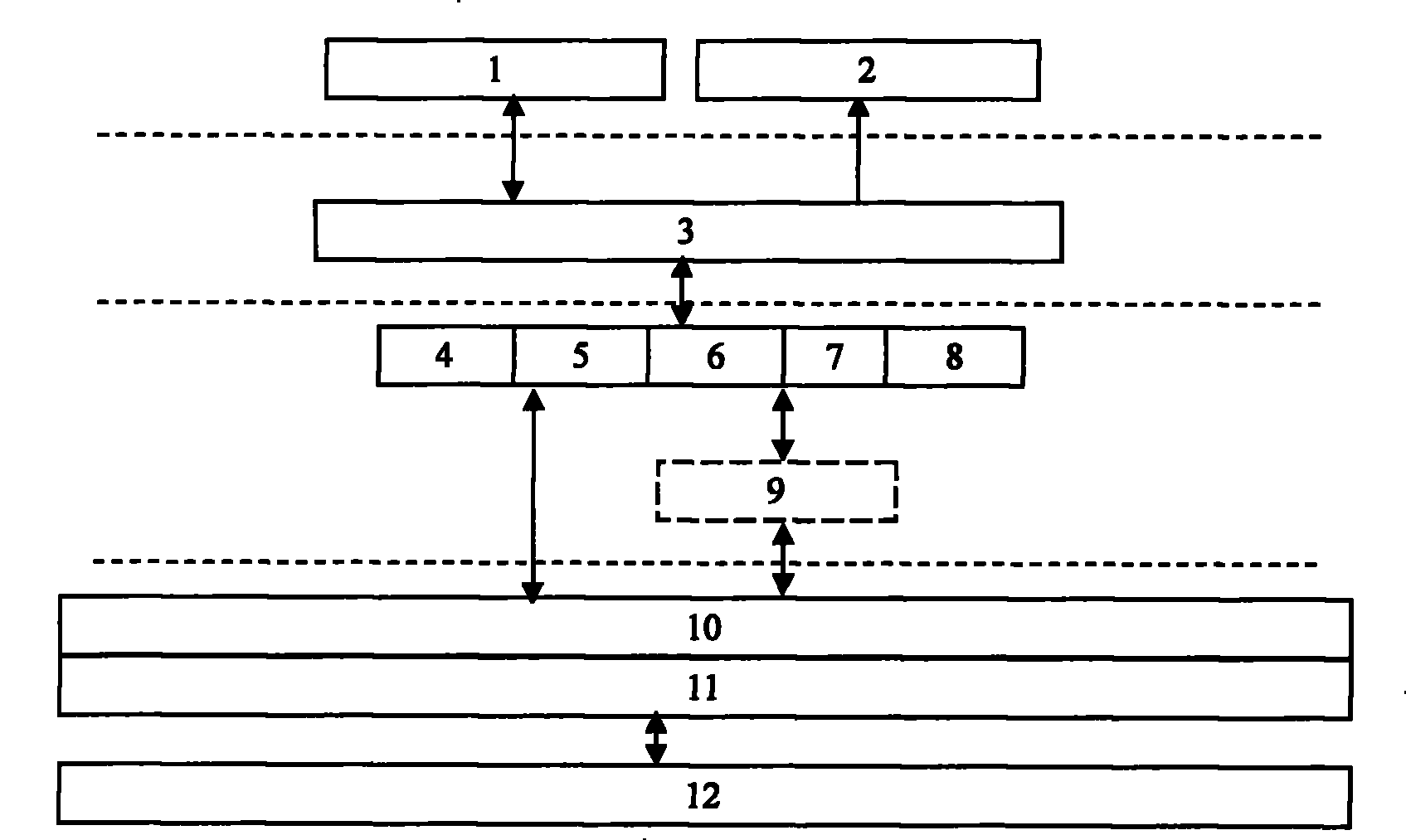

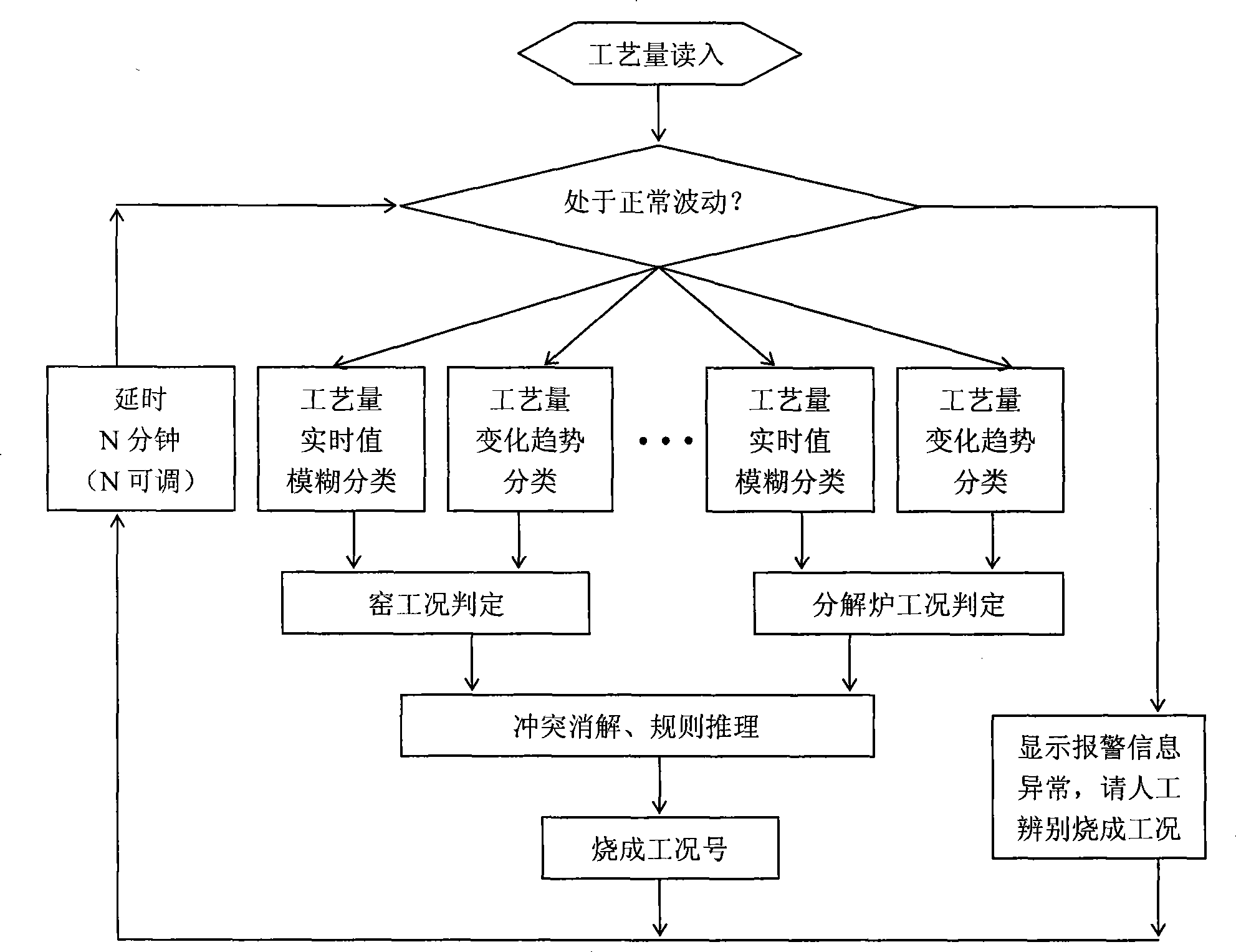

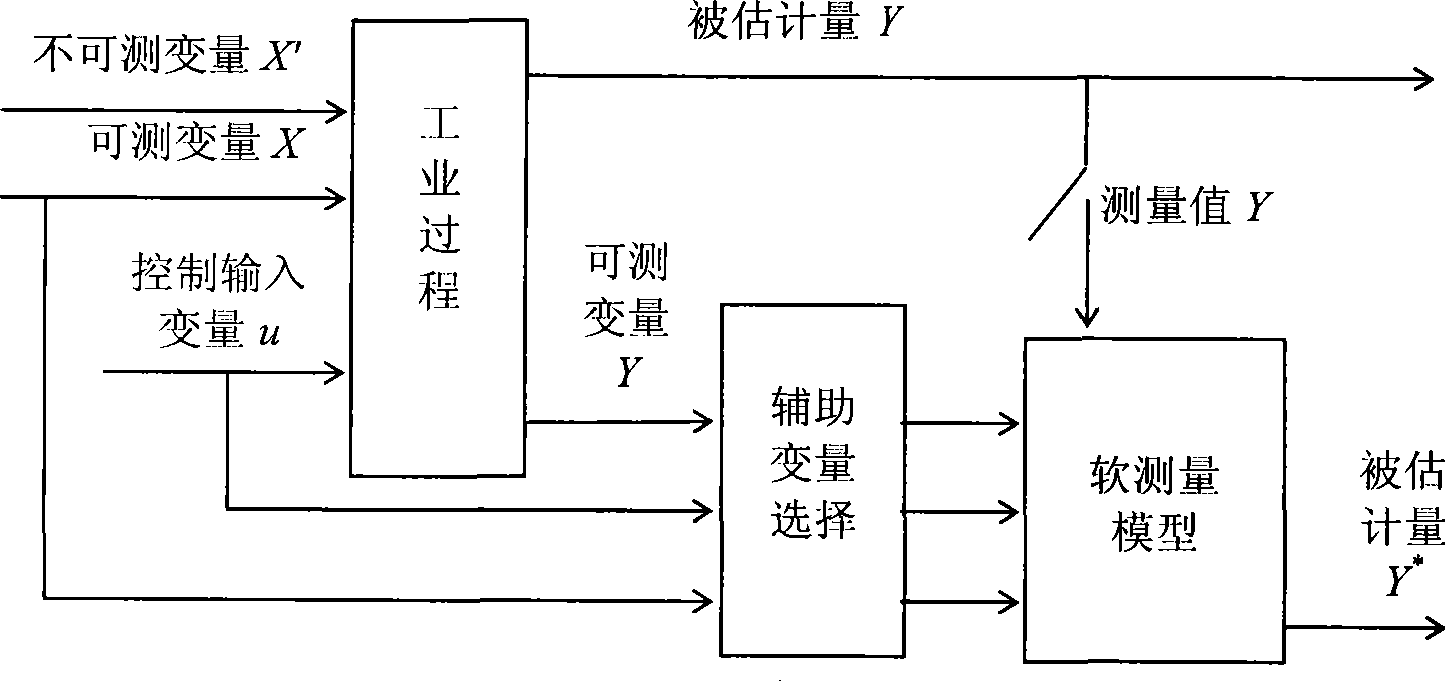

[0087] A comprehensive identification method for the firing conditions of a cement rotary kiln, the system structure diagram, the flow chart of the identification program, and the soft measurement structure diagram of the temperature in the firing zone are as follows: figure 1 , figure 2 and image 3 shown. The comprehensive identification method includes the following steps:

[0088] 1) The rotary kiln firing system is divided into the following sub-links: high-temperature fan link, preheater link, calciner link, kiln link and grate cooler link;

[0089] 2) The main process parameters of the rotary kiln firing system are directly measured by sensors;

[0090] 3) Carry out soft measurement of the firing zone temperature that cannot be obtained directly;

[0091] 4) classifying the real-time data values obtained by step 2) and step 3), and simultaneously determining the variation trend type of the real-time data values;

[0092] 5) According to sub-links, the real-time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com