Solid die forging crescent type suspending wire clip and manufacturing process for wire clip body

A technology of clamp body and suspension clamp, which is applied in the field of solid die forging crescent-shaped suspension clamp and clamp shell, which can solve the inflexible swing of the clamp main body, increase the volume of the clamp shell, and not easily absorb the energy of the wire and other problems, to achieve excellent anti-corona function, reduce corona phenomenon, improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

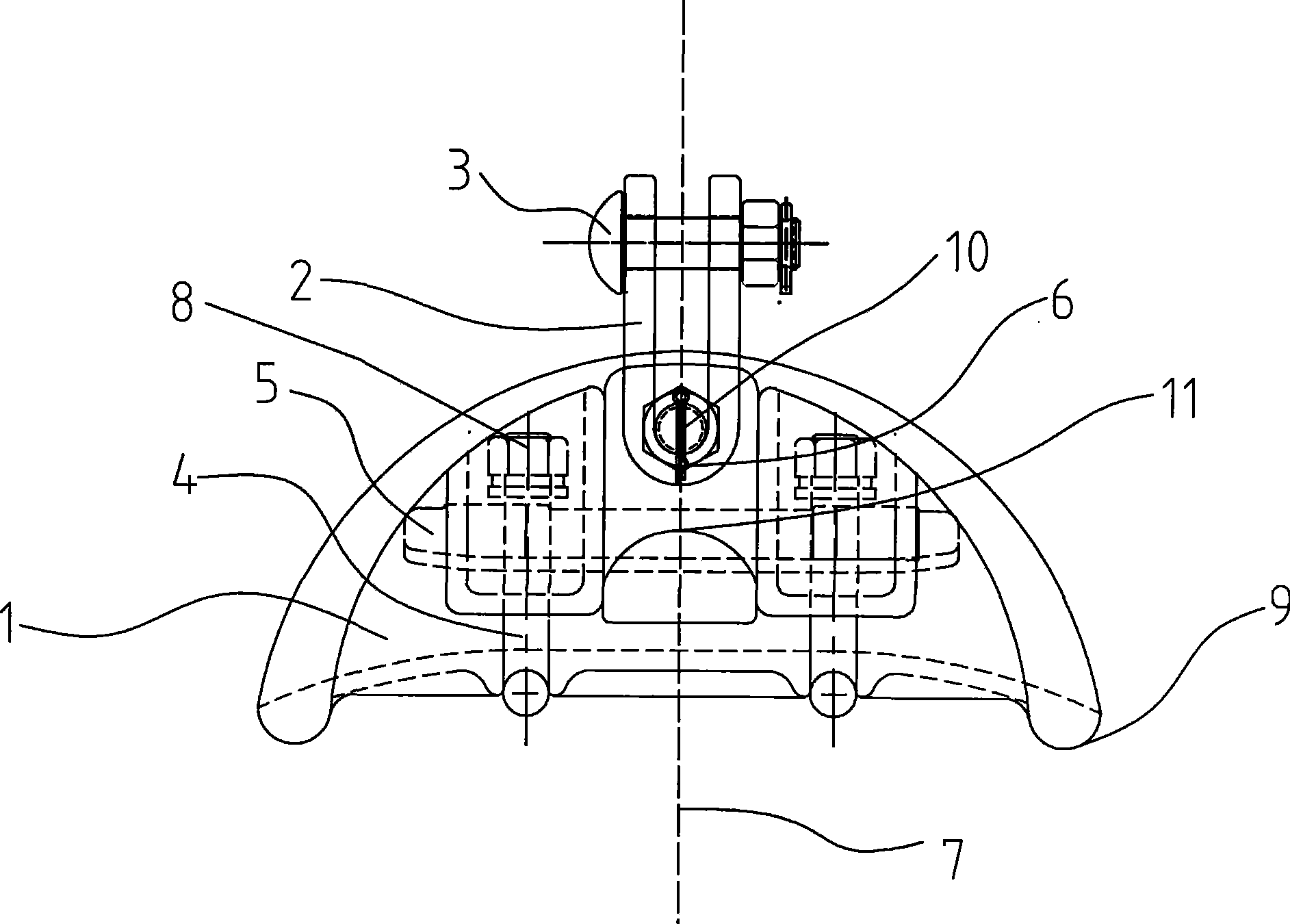

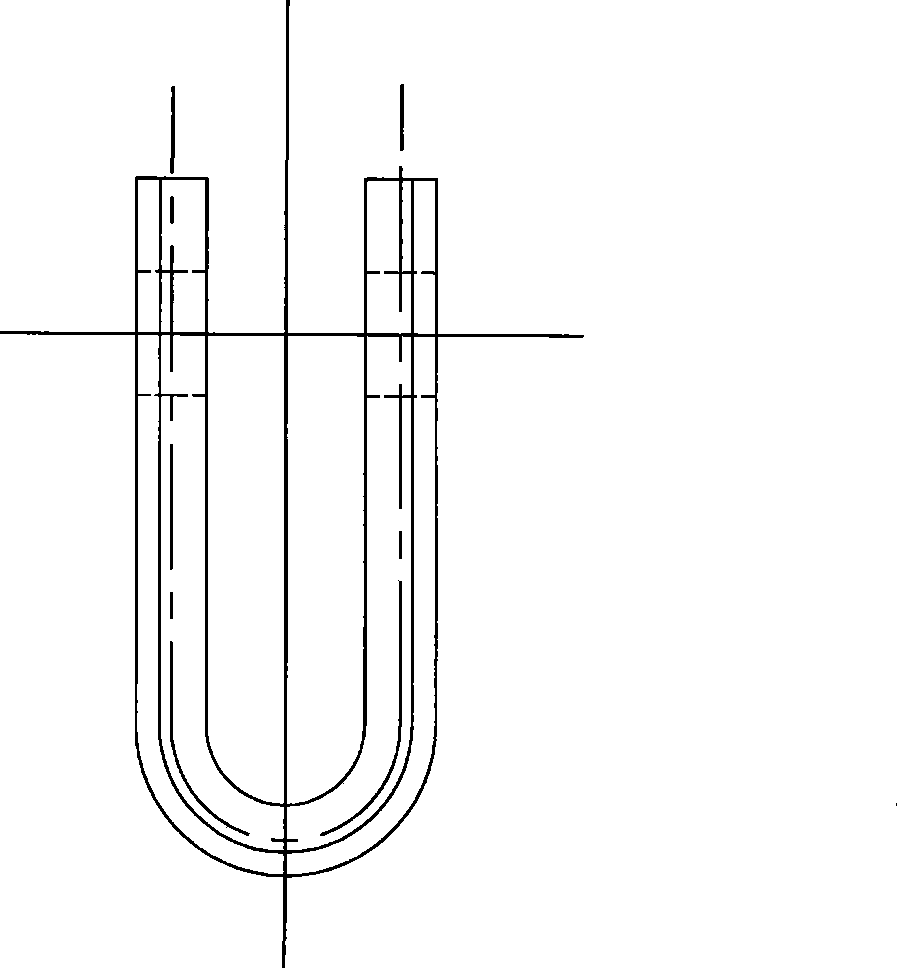

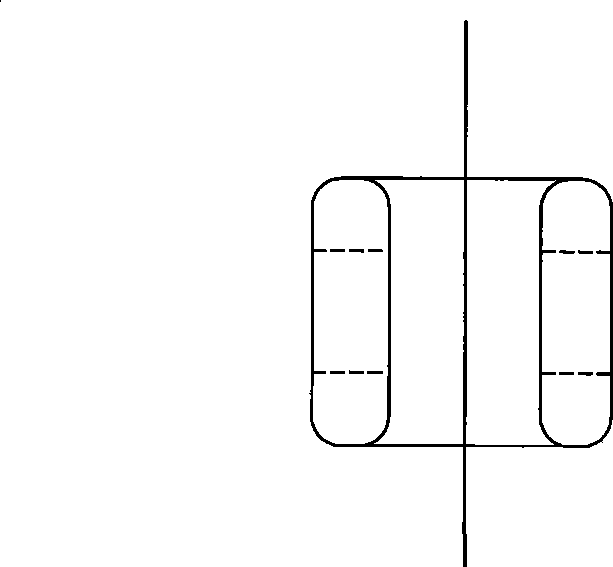

[0018] see figure 1 , solid die forging crescent-shaped suspension clamp, including a U-shaped cross-section clamp body 1, a U-shaped hanging plate 2, a connecting bolt 3, a U-shaped bolt 4, a pressure plate 5, and a pin 6. Its central line 7 is symmetrically provided with a group of bolt holes. After the U-shaped bolts 4 pass through the bolt holes of the clamp body 1, they pass through the holes of the pressure plate 5 and are fixed by nuts 8. The wire clamp between clamp body 1 is fixed, and U-shaped hanging plate 2 is connected with clamp body 1 through pin 6, and connecting bolt 3 passes the top of U-shaped hanging plate 3, plays the effect of suspending the whole suspension clamp.

[0019] The clamp body 1 is in the shape of a crescent as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com