Biological preparation capable of preventing and treating cruciferae club root and use thereof

A cruciferous and biological preparation technology, applied in the field of microorganisms, can solve problems such as clubroot disease of cruciferous family that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

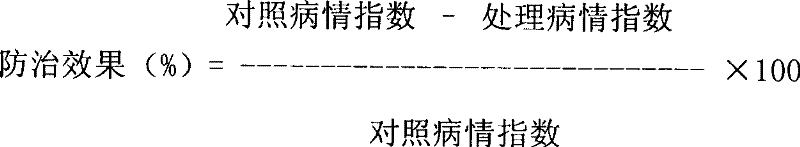

Method used

Image

Examples

Embodiment 1

[0067] Bacillus subtilis (Bacillus subtilis) XF-1 was transferred to a test tube slant medium, and the formula for test tube slant culture was: 1% tryptone, 0.5% yeast extract, 1% NaCl, 1.5% agar, pH7.0. Cultivate in an incubator at 30°C for 2 days to obtain test tube species.

[0068] Liquid fermentation medium formula: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0; inoculate the test tube into 500ml Erlenmeyer flask (200ml per bottle) liquid medium, at 30°C, the rotation speed is 150rpm Cultivate on a shaker for 48 hours, and the resulting culture solution is the biological preparation of the present invention.

Embodiment 2

[0070]At first will obtain test tube seed (with embodiment one), test tube seed is inoculated in 500ml Erlenmeyer flask (every bottle adorns 200ml) liquid medium, medium formula is: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0. Cultivate at 30° C. for 48 hours on a shaker with a rotating speed of 180 rpm, and the obtained culture solution is the biological preparation of the present invention.

Embodiment 3

[0072] At first will obtain test tube seed (with embodiment one), test tube seed is inoculated in 500ml Erlenmeyer flask (every bottle adorns 200ml) liquid medium, medium formula is: soybean flour 2.0%, corn flour 1.0%, glucose 0.3%, peptone 0.3%, CaCO 3 0.2%, (NH 4 ) 2 SO 4 0.05%, MgSO 4 .7H 2 O0.03%, KH 2 PO 4 0.1%, NaOH 0.1%, peanut oil 0.2%, defoamer 0.01%, pH6.8-7.0. Cultivate at 30° C. for 48 hours on a shaker with a rotating speed of 200 rpm, transfer the obtained culture liquid to a fermenter for fermentation production, and obtain the fermented liquid which is the biological preparation of the present invention.

[0073] Production conditions in the fermenter:

[0074] Tank temperature: The temperature in the fermenter is controlled at 30°C to 37°C, measured by a thermometer inserted into the culture medium, and adjusted by passing cooling water or hot water into the interlayer.

[0075] Tank pressure: The tank pressure of the fermenter is controlled at 0.5 / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com