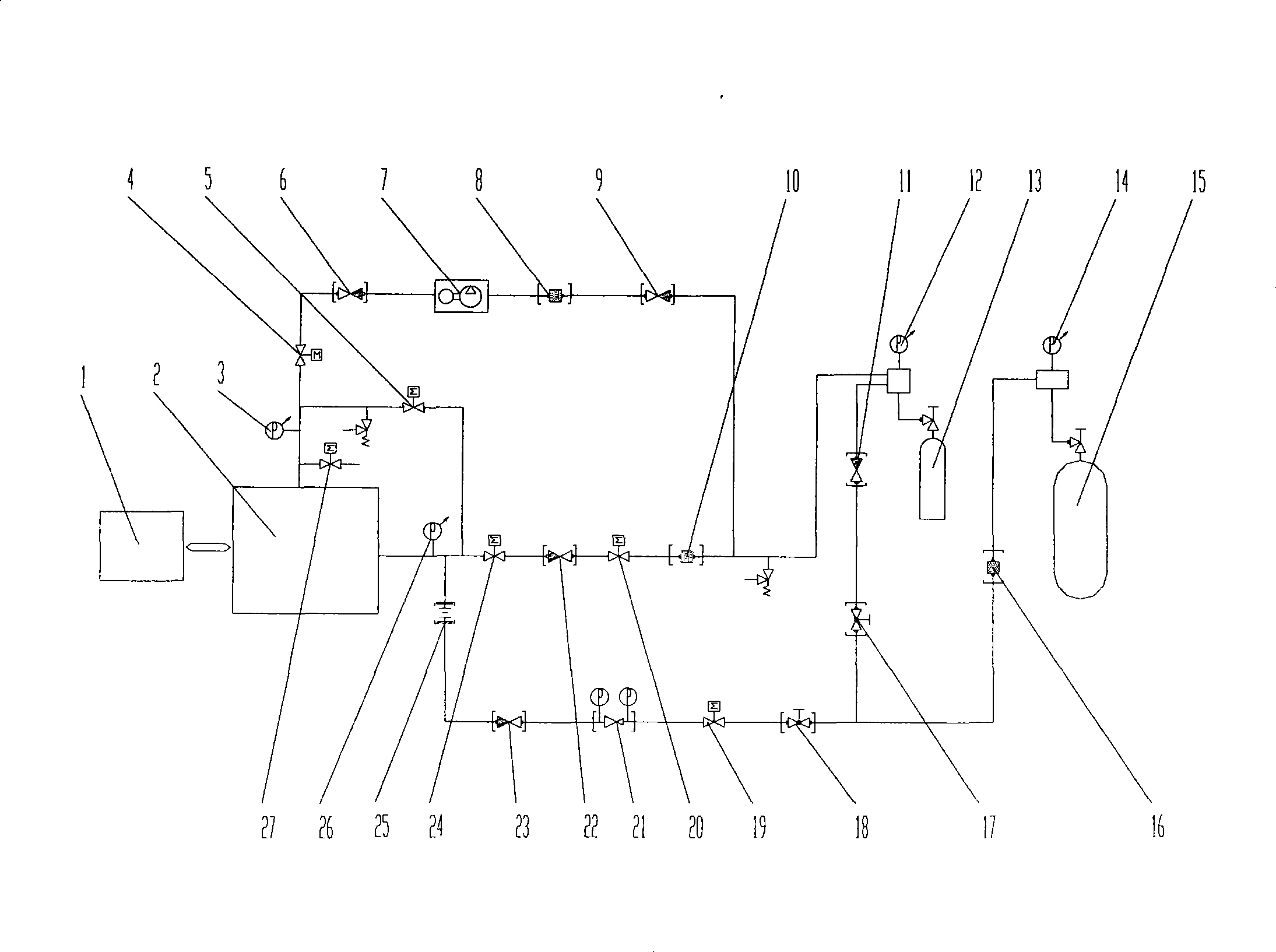

Stirling engine working substance system

A Stirling engine and working medium technology, which is applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve the problem of low temperature control accuracy of heating tubes and difficulty in applying Stirling engines and working medium types Limitation and other problems, to achieve the effect of reducing the consumption of working fluid, preventing the speed from being too high, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The STM company of the United States discloses the Stirling engine working medium system, which is only suitable for hydrogen working medium, which includes the internal working medium system, control module and external working medium system. The external working medium system consists of a hydrogen generating device and a hydrogen booster device. Composed of gas supply pipelines, the function is to pressurize and filter the generated hydrogen to the internal working fluid system of the Stirling engine. From the hydrogen generator to the Stirling engine, there are hydrogen booster devices, check valves, and ball valves connected in sequence. Or electromagnetic valves, filters and other equipment and valves, connected to the exhaust pipeline of the working fluid system in the machine, are vent valves, which can be manual ball valves or solenoid valves, and are used to discharge the working fluid in the machine. The hydrogen generating device uses the principle of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com