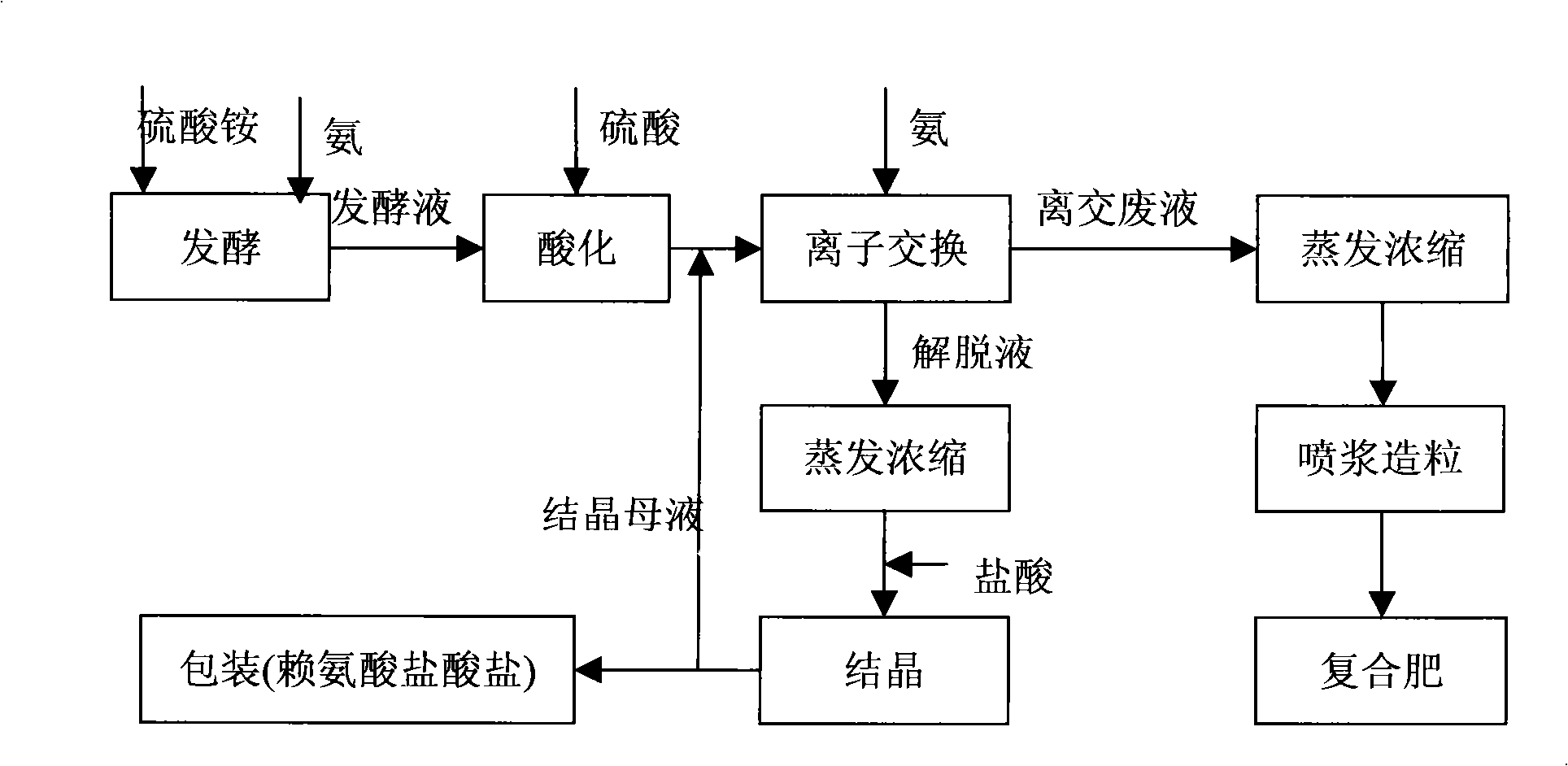

Method for processing ion exchange waste liquor of lysine production by fermentation method

A technology for lysine and lysine fermentation, which is applied in the field of fermentation and can solve the problems of difficulty in treatment and utilization of severance waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Ordinary electrodialyzer is a one-stage, single-stage ordinary electrodialyzer that operates independently, and the direction of liquid flow in adjacent compartments adopts the form of parallel flow. The area of the ion exchange membrane is 210mm×62mm, using JAM-10 type anion exchange membrane and JCM-1 type cation exchange membrane. Anion exchange membrane and cation exchange membrane form a two-compartment membrane stack structure (such as Figure 5 ) Repeat for 5 pairs. A titanium-coated ruthenium electrode is used as the anode plate, and a stainless steel electrode is used as the cathode plate. Both the partition and the net are polypropylene materials, the partition is a non-loop partition, and the partition is a woven mesh type.

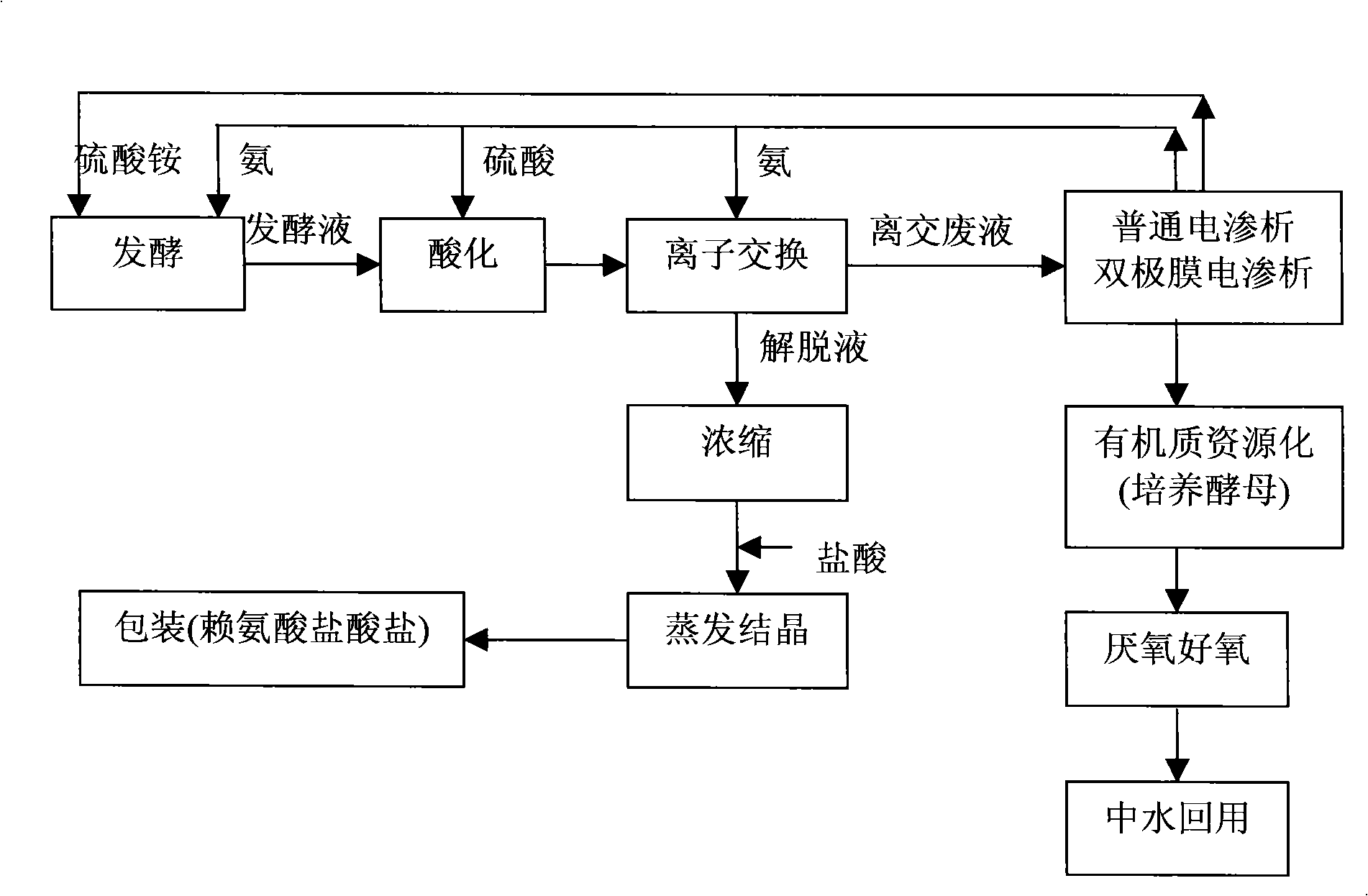

[0084] See figure 2 . Pass 3.0L of lysine separation waste liquid containing 60g / L ammonium sulfate and COD about 53000mg / L from China Ningxia Yipin Bioengineering Co., Ltd. into the salt chamber of an ordinary electrodialyzer; th...

Embodiment 2

[0087] Common electrodialyzer is with embodiment 1.

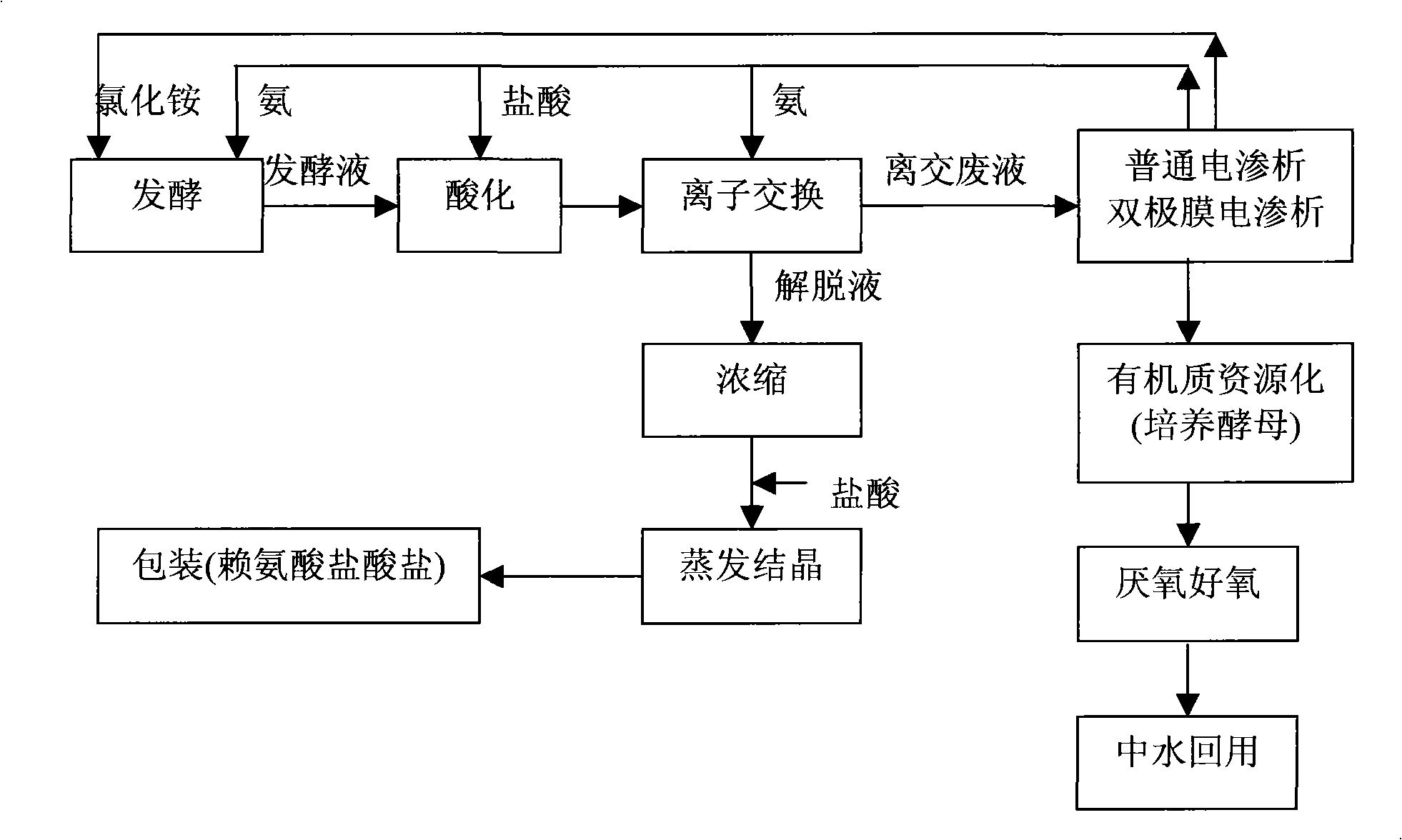

[0088] See image 3 . Pass 3.0L of lysine separation waste liquid containing 48g / L ammonium chloride and COD about 52000mg / L from China Ningxia Yipin Bioengineering Co., Ltd. into the salt chamber of the ordinary electrodialyzer; It is 3.0L 0.05mol / L ammonium chloride aqueous solution, and the two-electrode chamber liquid is 1L 0.25mol / L sodium sulfate solution.

[0089] Control current density 30mA / cm during operation 2 , the linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of feed liquid in each compartment is 30°C. Measure the conductance value of the feed solution in the salt chamber every 10 minutes, and stop the ordinary electrodialysis operation when the conductance value drops to 5 μS / cm. Obtain about 3.09 liters of ammonium chloride aqueous solution with a concentration of about 0.9mol / L in the concentrated chamber. The waste liquid obtained in the salt chamber of the ordinary e...

Embodiment 3

[0091] Common electrodialyzer is with embodiment 1.

[0092] See Figure 4 . Pass 6.0L of lysine separation waste liquid containing 72g / L ammonium nitrate and COD about 54000mg / L of China Ningxia Yipin Bioengineering Co., Ltd. into the salt chamber of an ordinary electrodialyzer; the initial liquid of the concentrated chamber is 1.0L of 0.05mol / L ammonium nitrate aqueous solution, and both electrode chamber liquids are 1L of 0.25mol / L sodium sulfate solution.

[0093] Control current density 30mA / cm during operation 2 , the linear velocity of liquid flow in each compartment is 3cm / s, and the temperature of feed liquid in each compartment is 30°C. Measure the conductance value of the feed solution in the salt chamber every 10 minutes, and stop the ordinary electrodialysis operation when the conductance value drops to 5 μS / cm. Obtain about 1.08 liters of ammonium nitrate aqueous solution with a concentration of about 5.0mol / L in the concentrated chamber. The waste liquid ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com