Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

A technology for hydraulic fracturing and gas extraction, which is applied in the direction of gas discharge, earthwork drilling, and fluid extraction, etc. It can solve difficult problems such as rapid excavation, large amount of engineering, and limited conditions, so as to improve single-hole drainage capacity, The effect of improving pumping efficiency and shortening pumping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

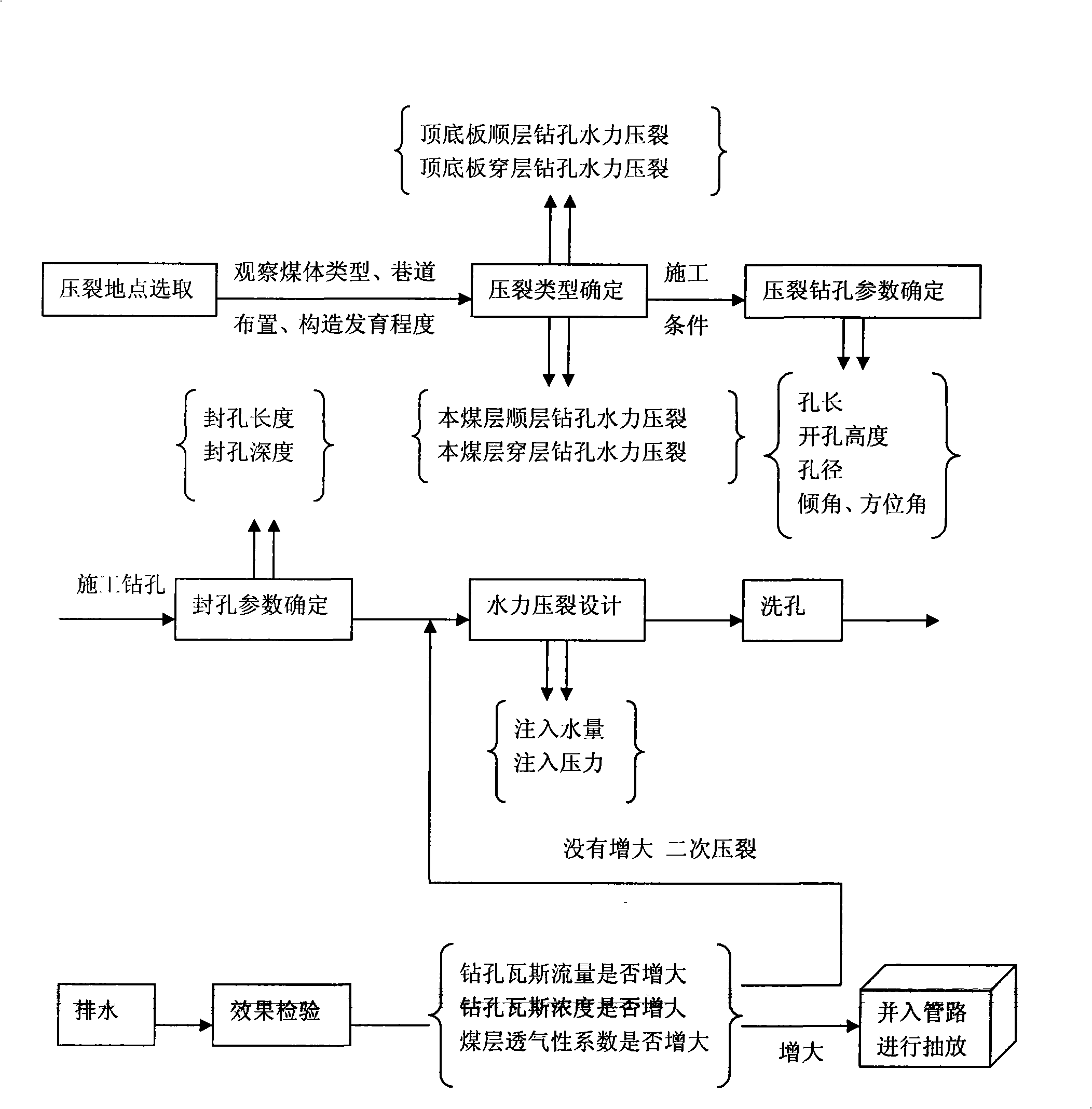

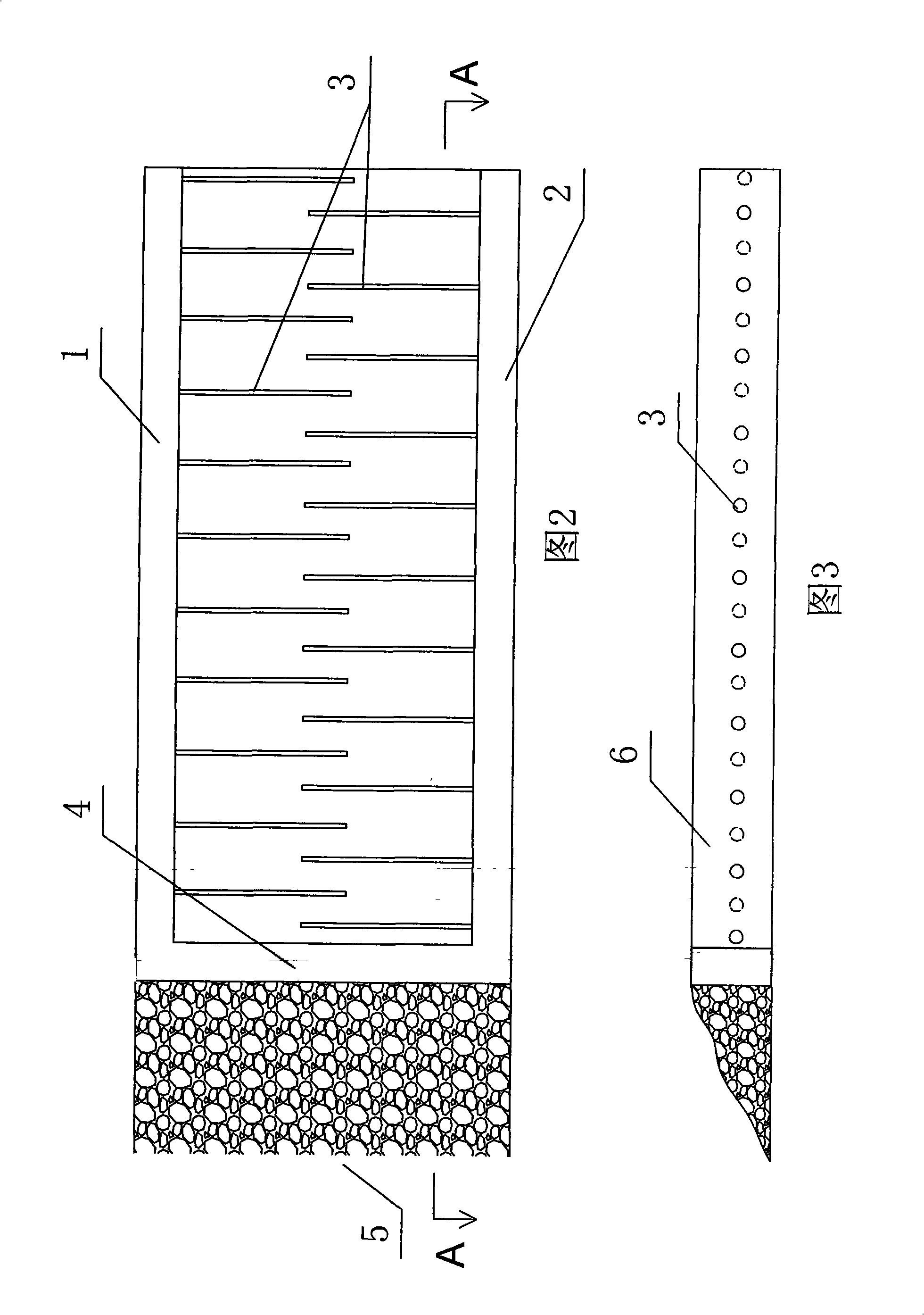

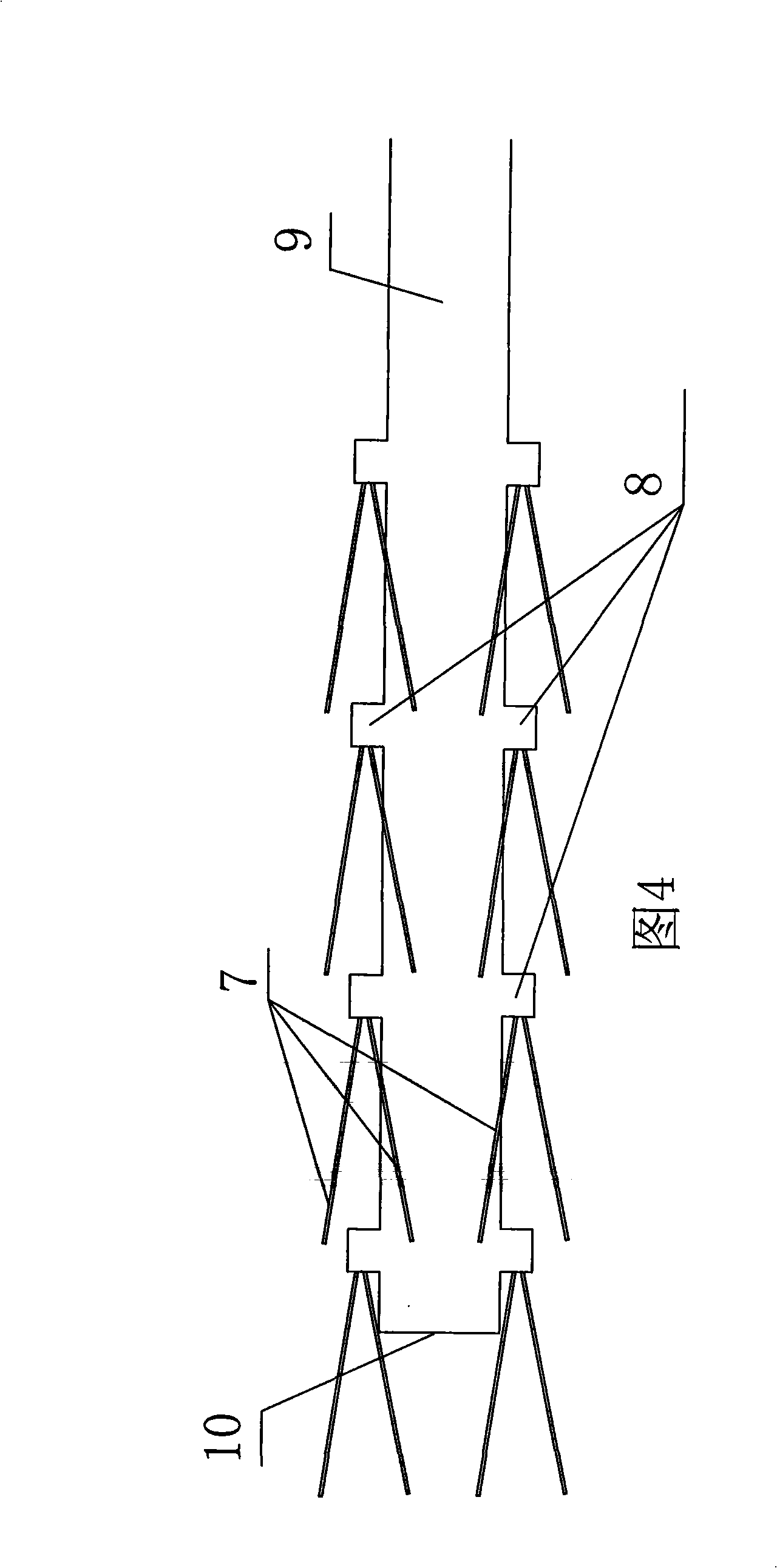

[0029] Embodiment: Underground coal mine drilling hydraulic fracturing anti-permeability gas drainage technology, including the following steps in turn: (1) select the fracturing site; (2) determine the pressure type according to the observed coal body type, roadway layout and structural development degree, The hydraulic fracturing of roof and floor drilling along the bedding, roof and floor through-bed drilling hydraulic fracturing, the coal seam's bedding drilling hydraulic fracturing or the coal seam's through-bed drilling hydraulic fracturing can be used; (3) Determine the drilling parameters for construction Drilling, drilling parameters include hole length, hole height, hole diameter, inclination, azimuth; (4) design hydraulic fracturing, including injection water volume and injection pressure; (5) washing holes; (6) drainage; (7) Check the fracturing effect, if it meets the requirements, proceed downward, if it does not meet the requirements, turn to step (4); (8) enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com