Endogenous heat type hemicontinuous reduction furnace for producing magnesium, calcium and strontium

A semi-continuous, metal magnesium technology, applied in the field of internal heating metal magnesium, strontium reduction equipment, and calcium, can solve the problems of small reduction tank, low fuel utilization rate, and small primary capacity, so as to reduce the construction area and improve combustion Effect, effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

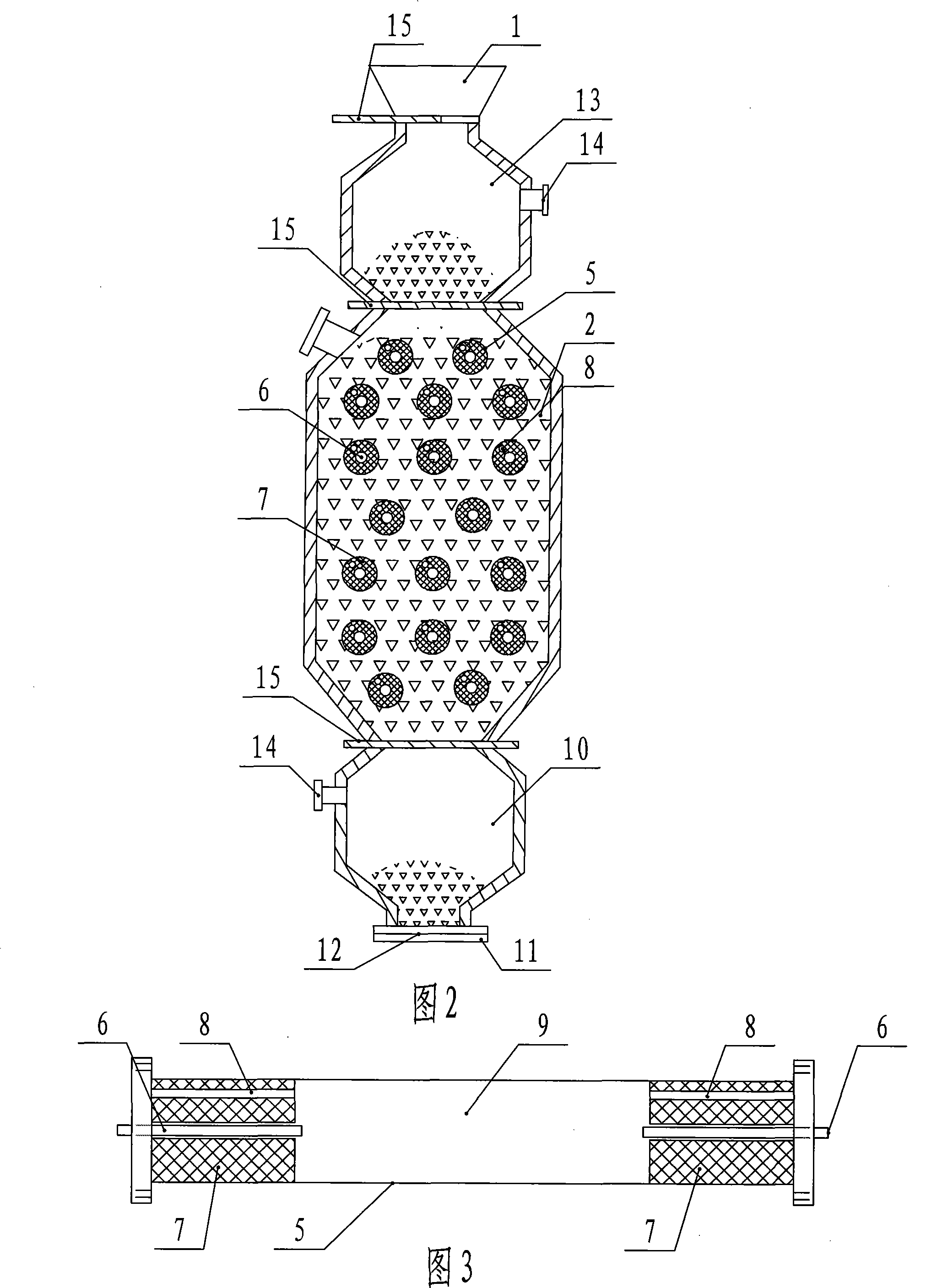

[0027] The internal heating semi-continuous reduction furnace for the production of metal magnesium, calcium and strontium, as shown in Figures 1 and 2, includes a furnace body, a feeding hopper 1 is arranged above the furnace body, a reduction chamber 2 is arranged in the furnace body, and a reduction chamber 2 is installed above the furnace body. There is a vacuum suction pipe 4 connected to the crystallizer 3, and the crystallizer and the vacuum suction pipe are respectively arranged on both sides of the reduction chamber, so as to be used alternately in the continuous production process; the internal heating pipe 5 is arranged transversely through the reduction chamber 2, adjacent The inner heating pipes are used as feeding reaction gaps, and the inner heating pipes 5 are evenly arranged in the reduction chamber 2; Connected regenerator 7, the regenerator 7 is inserted into the fuel core tube 6 connected with the fuel, the regenerator 7 is also provided with an ignition hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com