Process for producing long-chain alkyl-phenyl modified silicone oil

A long-chain alkanephenyl and alkanephenyl technology, which is applied in the field of preparation of long-chain alkanephenyl modified silicone oil, can solve the problems of numerous steps, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

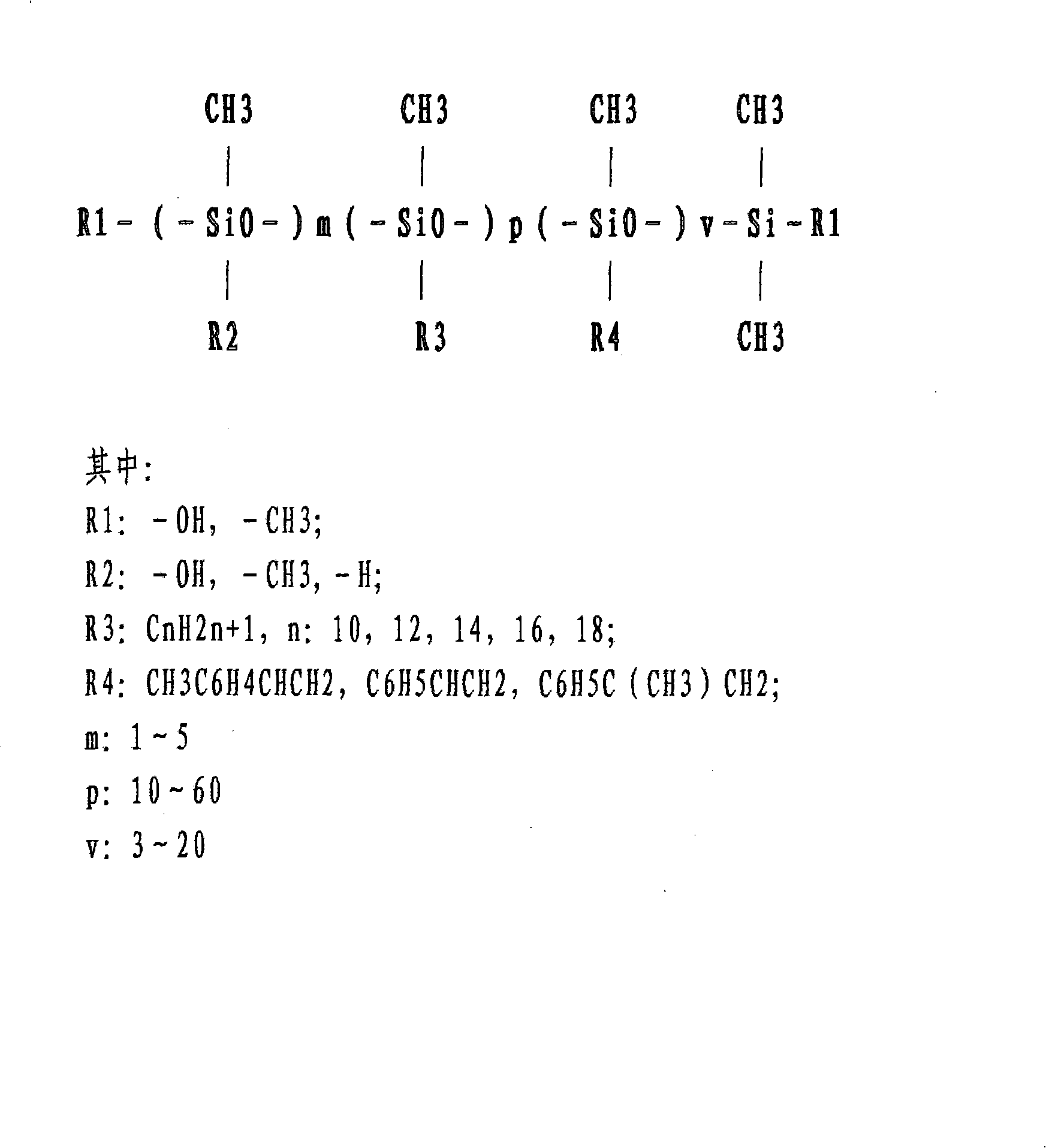

Image

Examples

Embodiment 1

[0013] Product Name: Long-chain alkylphenyl modified silicone oil (RH-1)

[0014] Catalyst: Dissolve 1g of chloroplatinic acid in 200g of isopropanol, take 2.5g;

[0015] Raw materials: Hydrogen-containing siloxane: 150g of 202 hydrogen-containing silicone oil;

[0016] Long-chain carbon olefins: 400g of α-dodecene, purity 99-99.9%;

[0017] Styryl hydrocarbons: α-methylstyrene 78g;

[0018] Process conditions: a reactor with a stirrer, thermometer, heating, cooling, and vacuum device, with a volume of 1000ml; addition reaction process: under an atmospheric pressure, add styrene-based hydrocarbons to the reactor, raise the temperature to 50 ° C, drop The catalyst is added, and after 5 minutes, the hydrogen-containing siloxane is added dropwise. After the dropwise addition, the long-chain carbon olefin is added dropwise. The temperature is controlled at 100° C., and the reaction is carried out for 6 hours. After testing the residual hydrogen content to be qualified, lower th...

Embodiment 2

[0024] Product Name: Long chain alkyl phenyl modified silicone oil (RH-2)

[0025] Catalyst: Dissolve 1g of chloroplatinic acid in 200g of isopropanol, take 2.6g;

[0026] Raw material: Hydrogen-containing siloxane: 200g of 202 hydrogen-containing silicone oil;

[0027] Long-chain carbon olefins: α-dodecene, a total of 500g divided into two parts of 200g and 300g, with a purity of 99-99.9%;

[0028] Styryl hydrocarbons: styrene 100g;

[0029] Process conditions: a reactor with a stirrer, thermometer, heating, cooling, and vacuum device, with a volume of 1000ml; addition reaction process: 200g of long-chain carbon olefins and styrene-based hydrocarbons are added to the reactor at an atmospheric pressure , the temperature was raised to 70°C, the catalyst was added dropwise, the temperature was raised to 90°C, the hydrogen-containing siloxane was added dropwise, and the temperature was controlled at 130°C. After the dropwise addition, 300g parts of long-chain carbon olefins wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com