Rotary atomizer head type paining machine

A technology of rotary atomization and coating machine, which is applied in the direction of spraying device, electrostatic spraying device, spraying device with movable outlet, etc., which can solve the problems of poor coating quality, bending of rotating shaft, bearing damage, etc., and achieve improved coating quality. The effect of improving the quality of installation, improving reliability and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

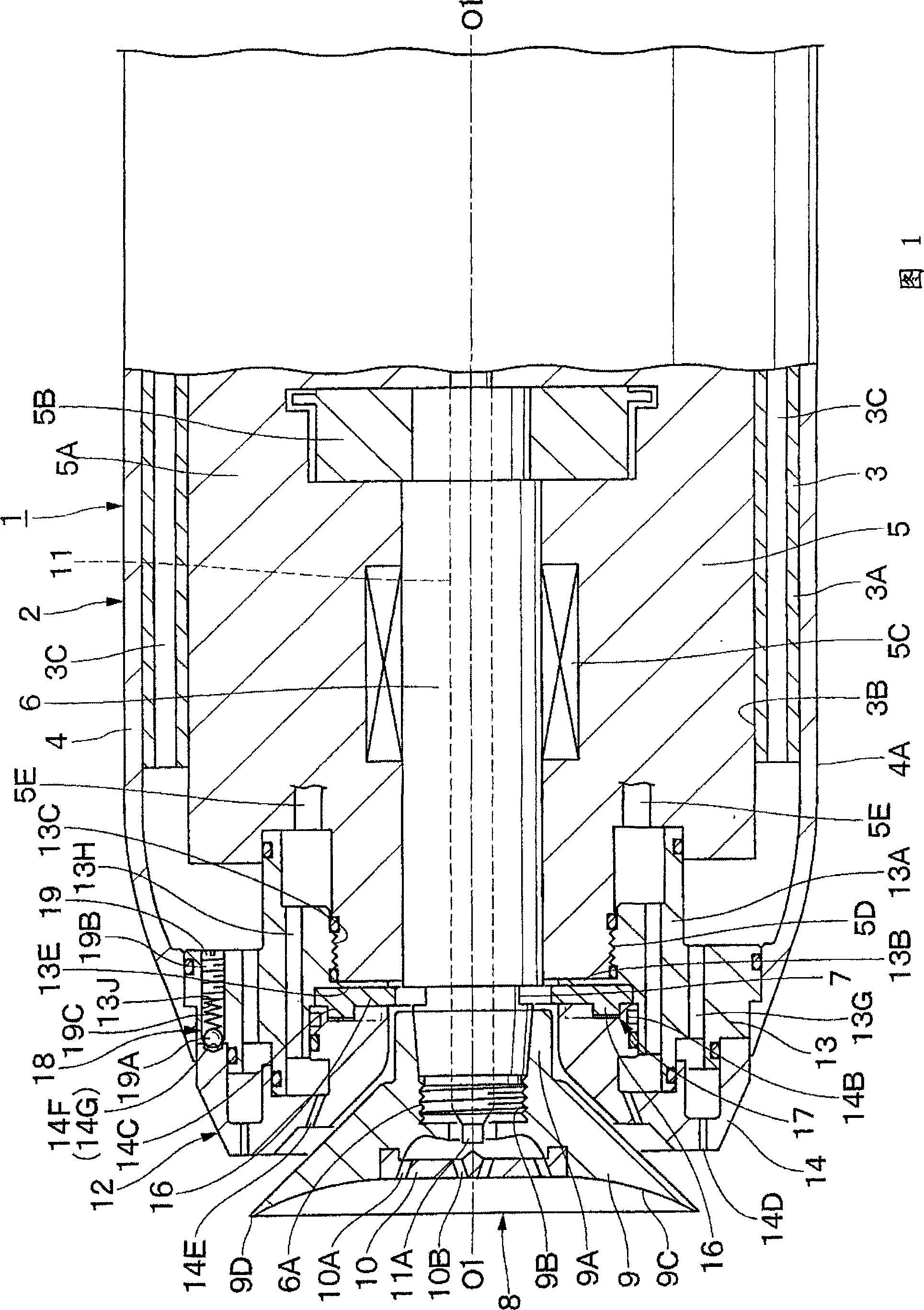

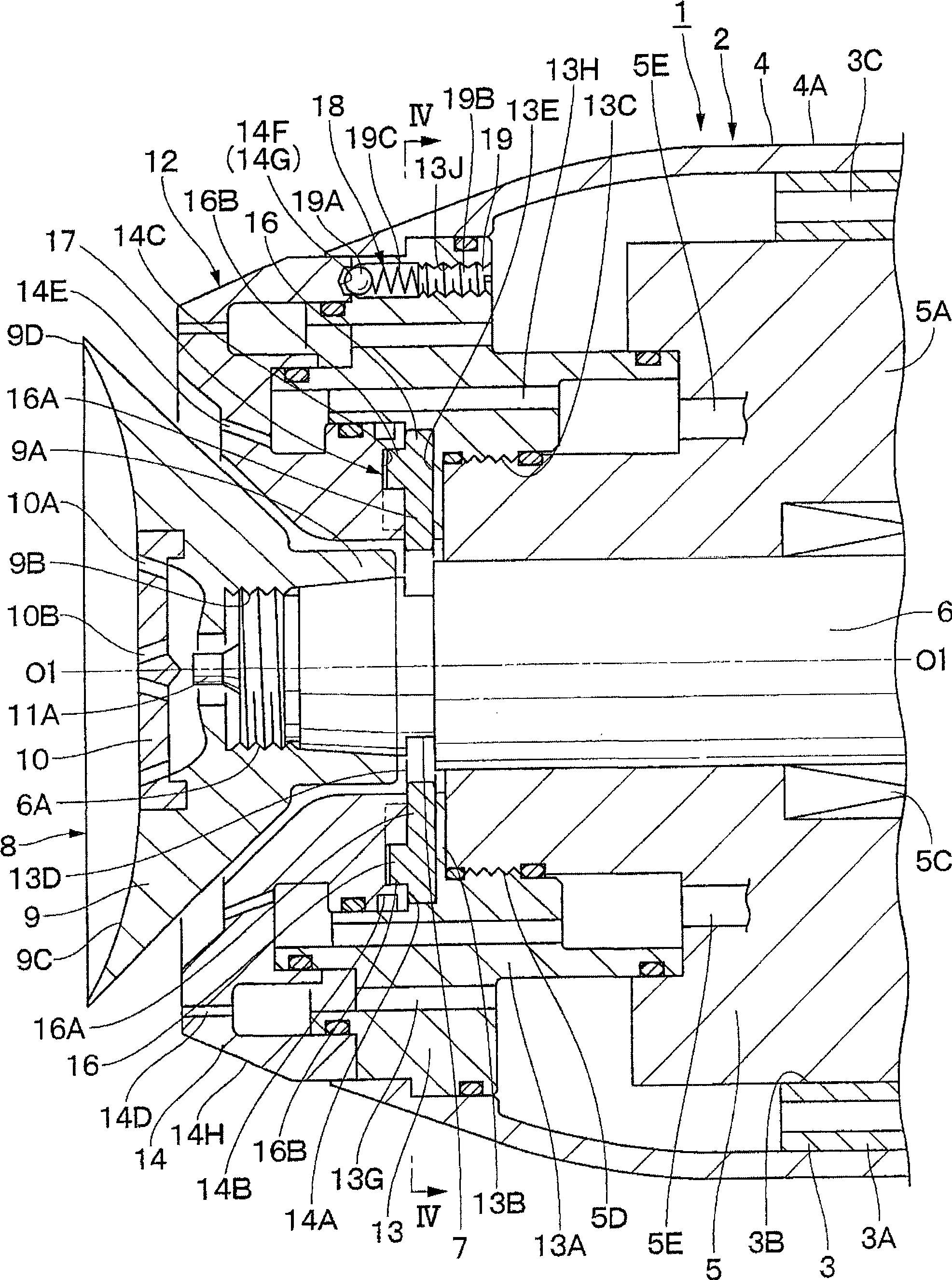

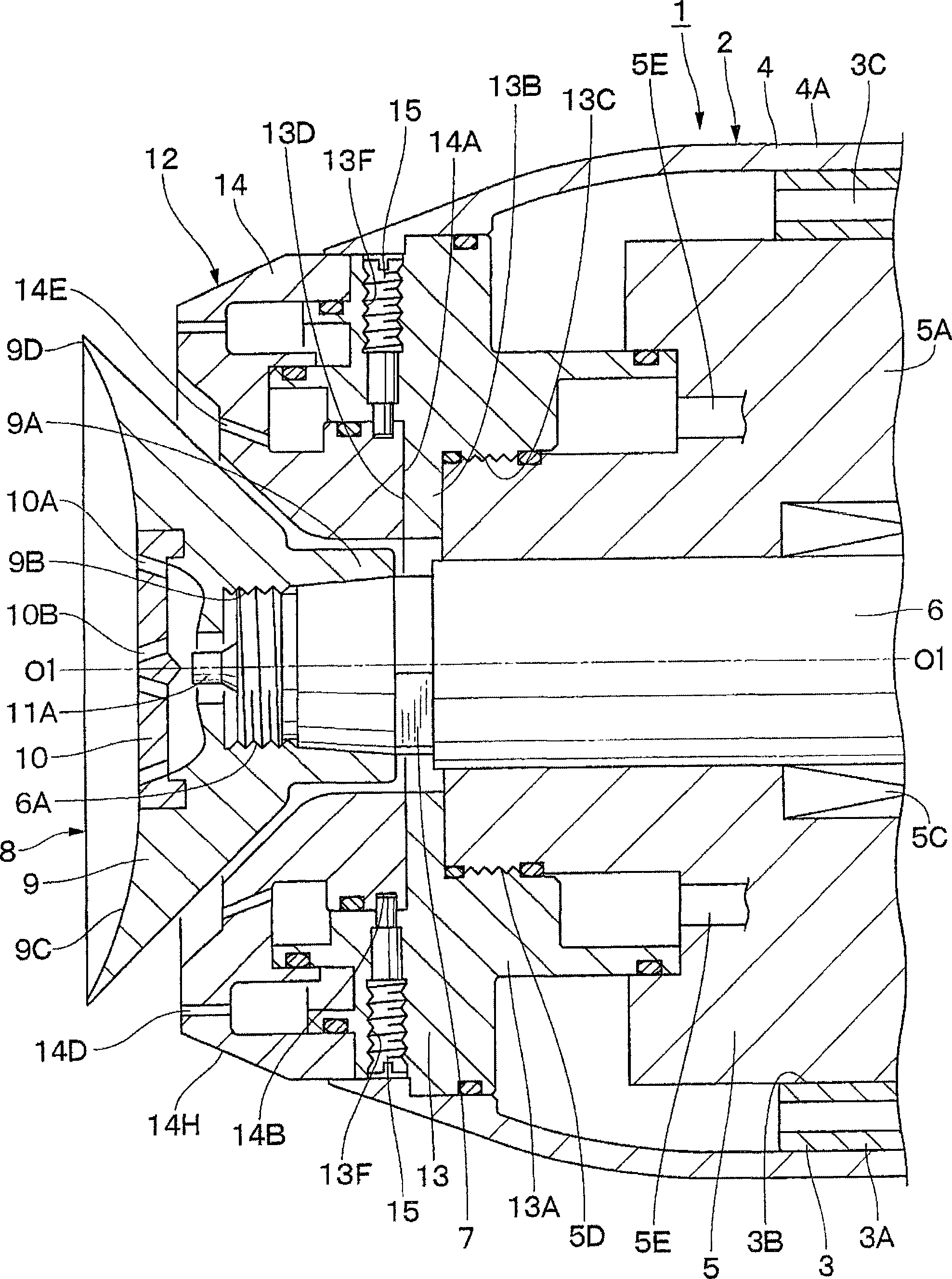

[0052] Hereinafter, a rotary atomizing head type coating machine according to an embodiment of the present invention will be described in detail with reference to the drawings.

[0053] First, Figure 1 to Figure 8 The first embodiment of the present invention is shown.

[0054] In FIG. 1 , reference numeral 1 denotes a rotary atomizing head type coating machine according to a first embodiment. This coating machine 1 is attached to the front-end|tip of the arm (not shown) of a robot for coating, a reciprocating mechanism, etc., for example. Moreover, the rotary atomizing head type coating machine 1 roughly includes a housing 2, an air motor 5, a rotating shaft 6, a fitting part 7, a rotary atomizing head 8, a feeding pipe 11, a shaping air ring 12, and the like which will be described later.

[0055] Reference numeral 2 is a casing forming the outer shape of the coating machine 1 . The case 2 is composed of a case main body 3 on the inside and a cover 4 on the outside. Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com