Drinking vessel fillable from the bottom and apparatus for dispensing a beverage therein

一种饮用容器、饮料的技术,应用在分配装置、特殊分配装置、液体流量进行控制的装置等方向,能够解决不卫生等问题,达到避免泄漏、缩短稳定时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

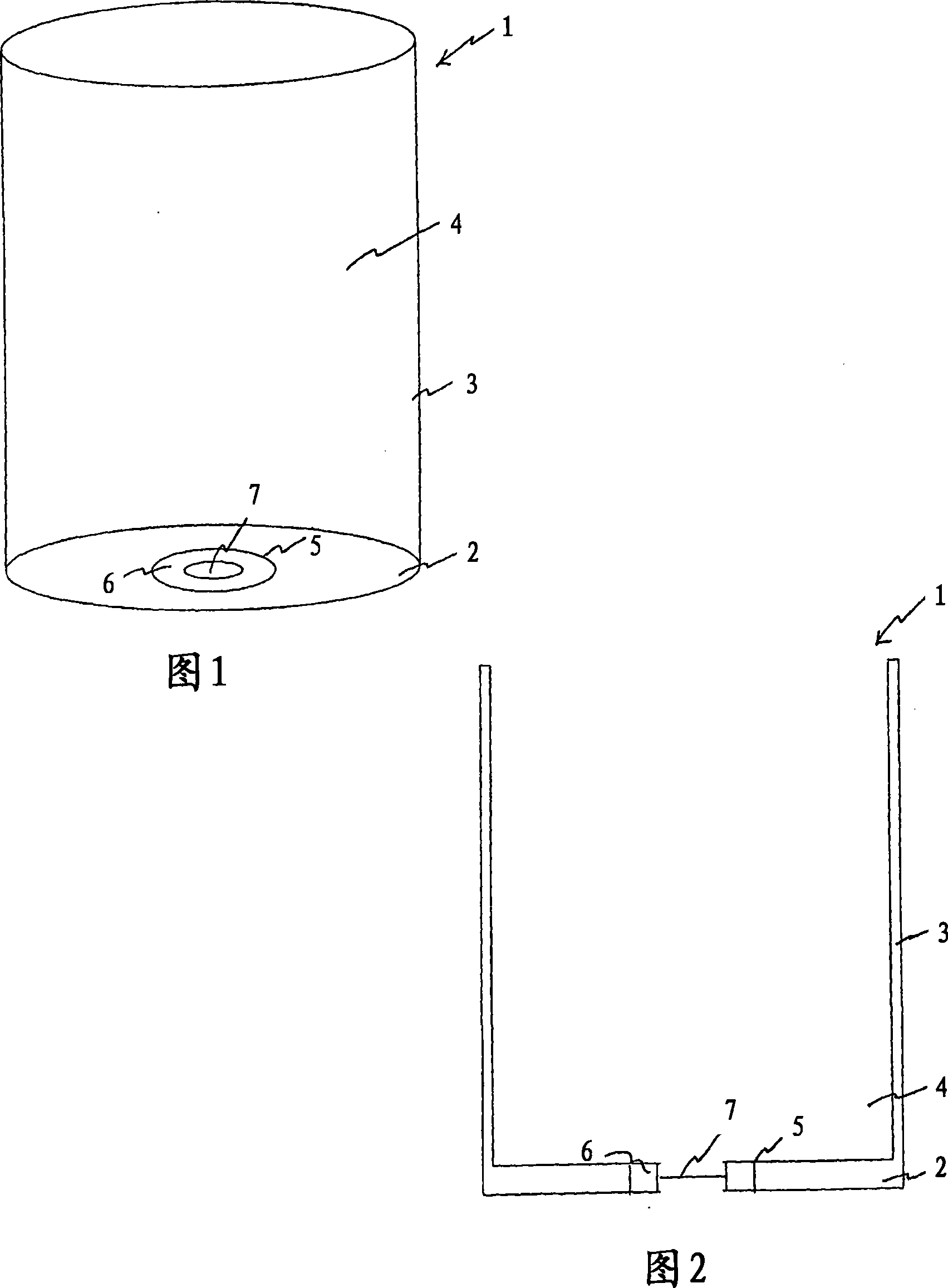

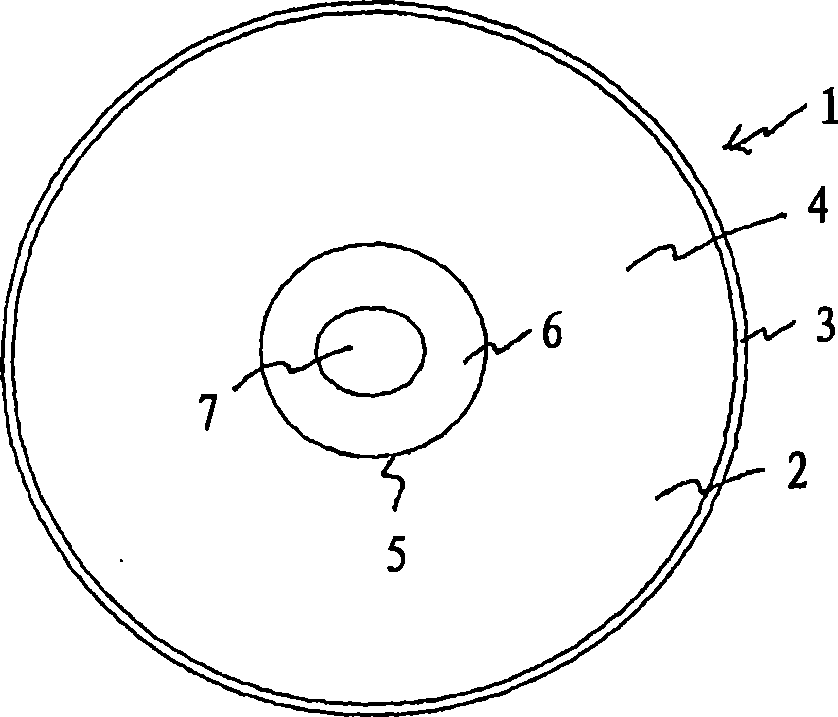

[0036] Referring to Figures 1-3, a drinking container 1 comprising a base 2 and a substantially cylindrical wall 3 is depicted. The bottom 2 and the wall 3 together define a chamber 4 containing the beverage. The container 1 also comprises a sealable aperture 5 provided in the base 2 for filling the chamber 4 with beverage.

[0037] The container 1 further comprises a non-return valve 6 located in the bore 5 . A one-way valve 6 allows beverage to be dispensed into the chamber through the aperture 5, while preventing beverage from flowing out of the container through the aperture. In the embodiment shown, the non-return valve is of the type comprising a membrane 7 of silicone rubber with a slit disposed therein.

[0038] In use, beverage is dispensed through the sealable aperture 5 of the base 2 into the container. After the beverage has been dispensed into the container, the aperture is automatically sealed by the valve 6 .

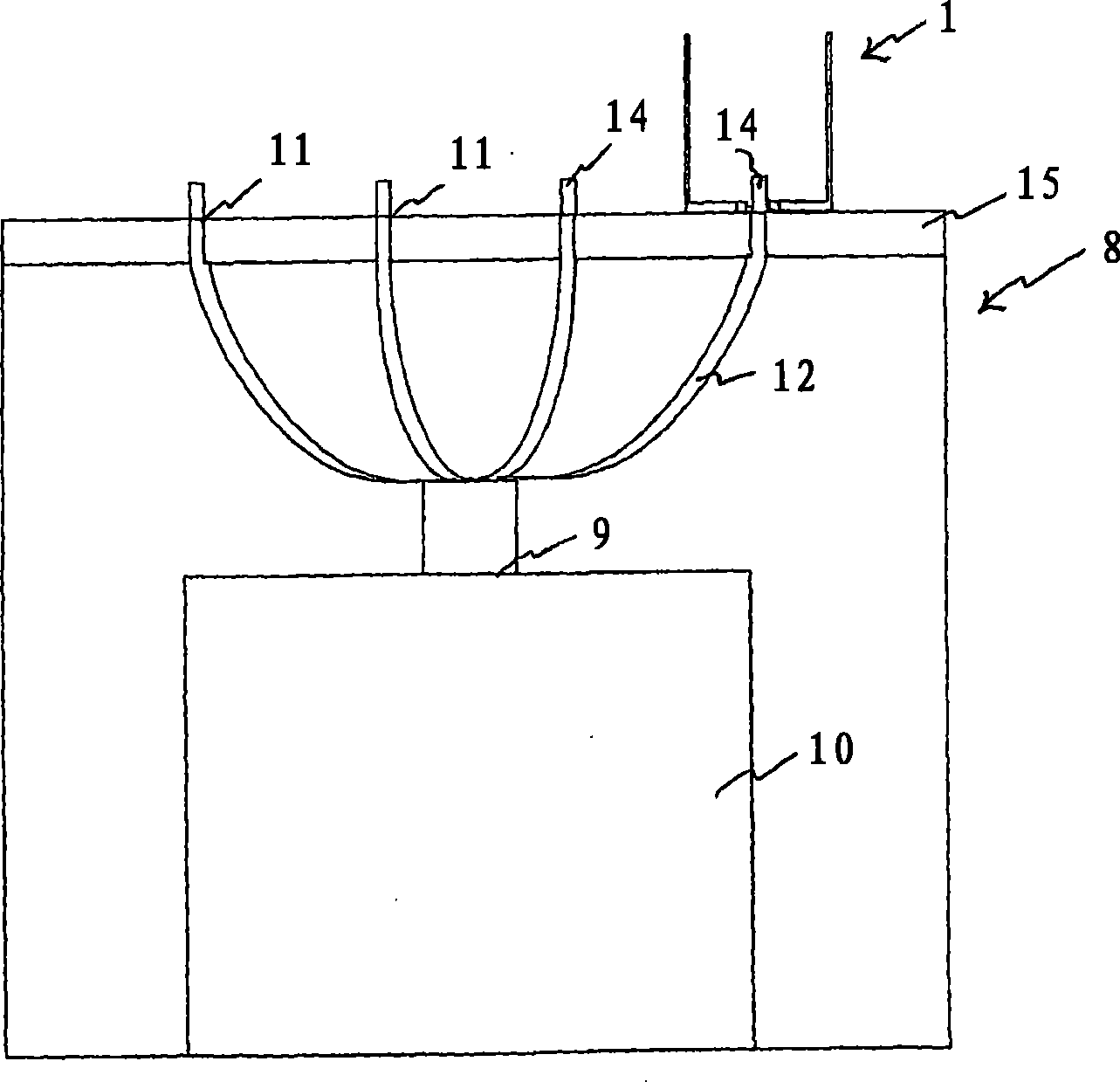

[0039] now refer to Figure 4 and 5 , the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com