Winding machine

A technology of winding machine and bobbin, which is applied in the field of winding machine to achieve the effect of enhancing the rigidity of the bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

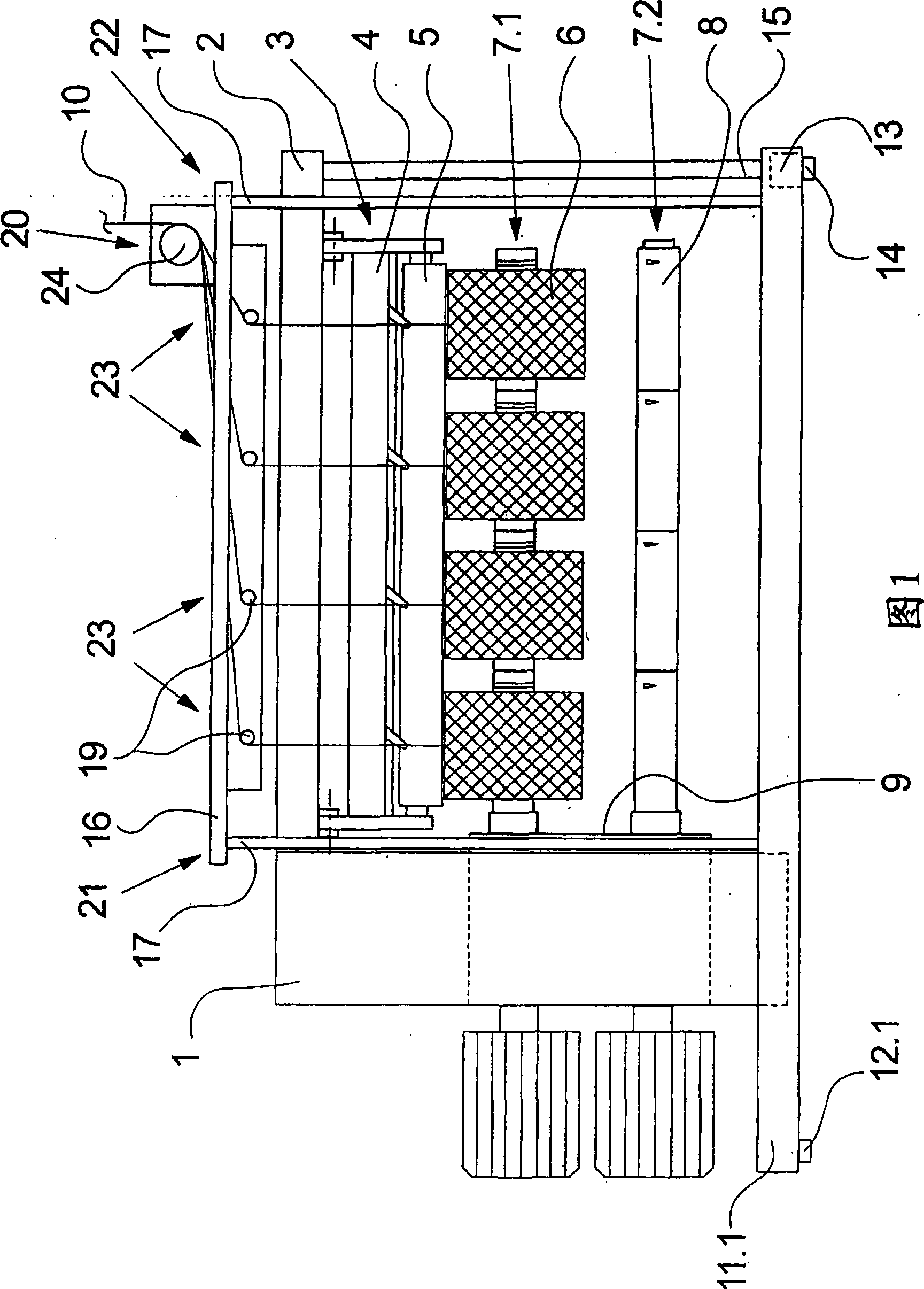

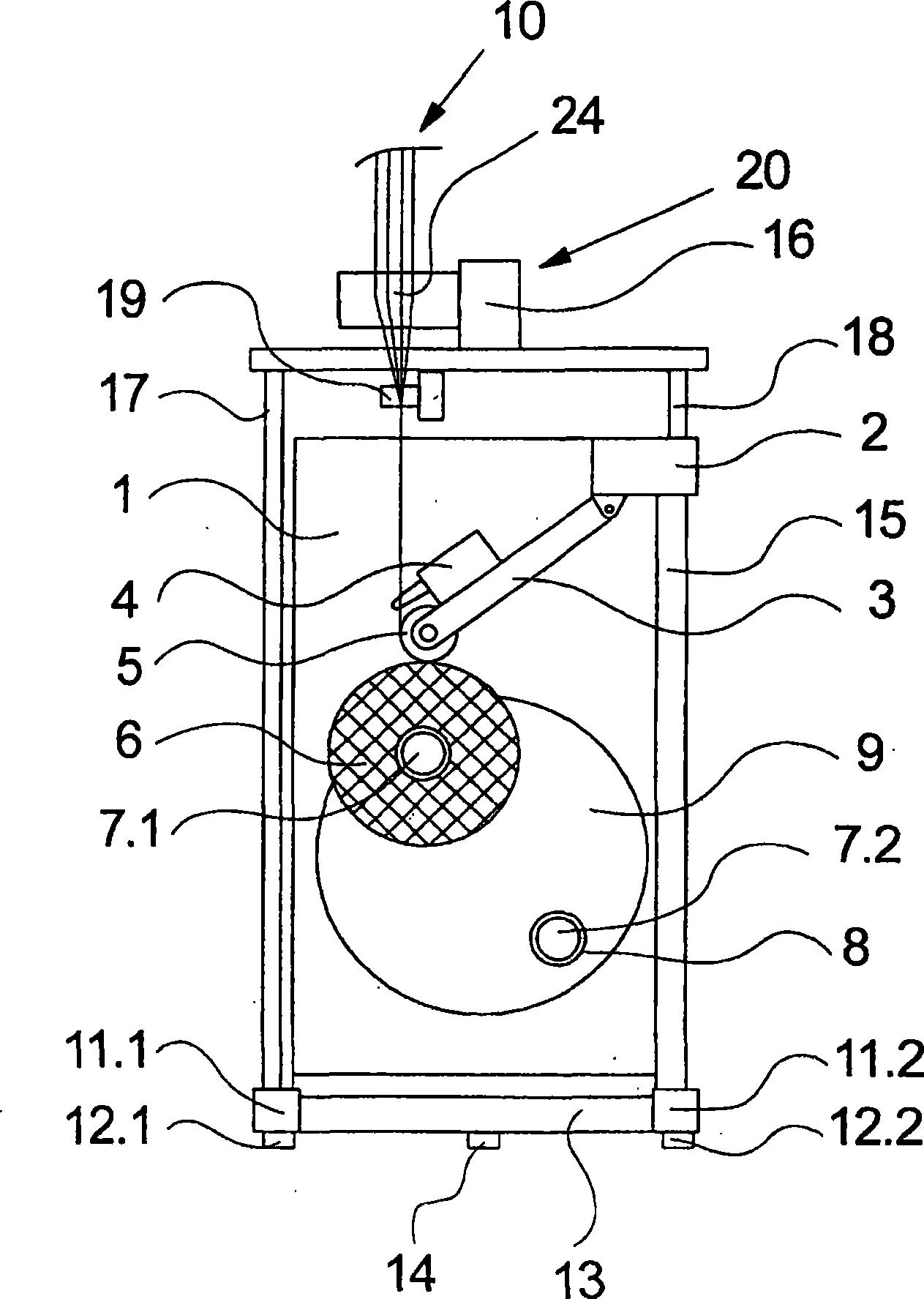

[0026] FIG. 1 shows a side view of a first embodiment of a winding machine according to the invention. figure 2 A front view of the same winder is shown. The following description refers to these two figures.

[0027] The housing 1 of the winding machine supports a rotatable turntable 9 in which two bobbin spindles 7.1, 7.2 and their drives are rotatably mounted. By rotating the turntable 9, the bobbin spindles 7.1, 7.2 can be swiveled alternately into a lower changing area and an upper winding area. In the winding area, a pressure roller 5 is arranged above the bobbin spindle 7.1. Turntable 9 is at the same time the device by which the distance between pressure roller 5 and winding spindle 7.1 increases as the diameter of the package increases.

[0028] In the winding machine shown here, four winding heads 23 and four bobbins 6 are shown to simplify the illustration. This is typical for one or for a greater number of winding heads. Especially in the bobbin spindles with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com