Battery assembly

A battery and component technology, applied in the field of battery components, can solve the problems of accumulation, condensation of cooling air, difficult short circuit, etc., and achieve the effect of compact overall structure, reducing vehicle space and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Hereinafter, the battery module of the present invention will be described in detail with reference to specific examples and experimental examples.

no. 1 example

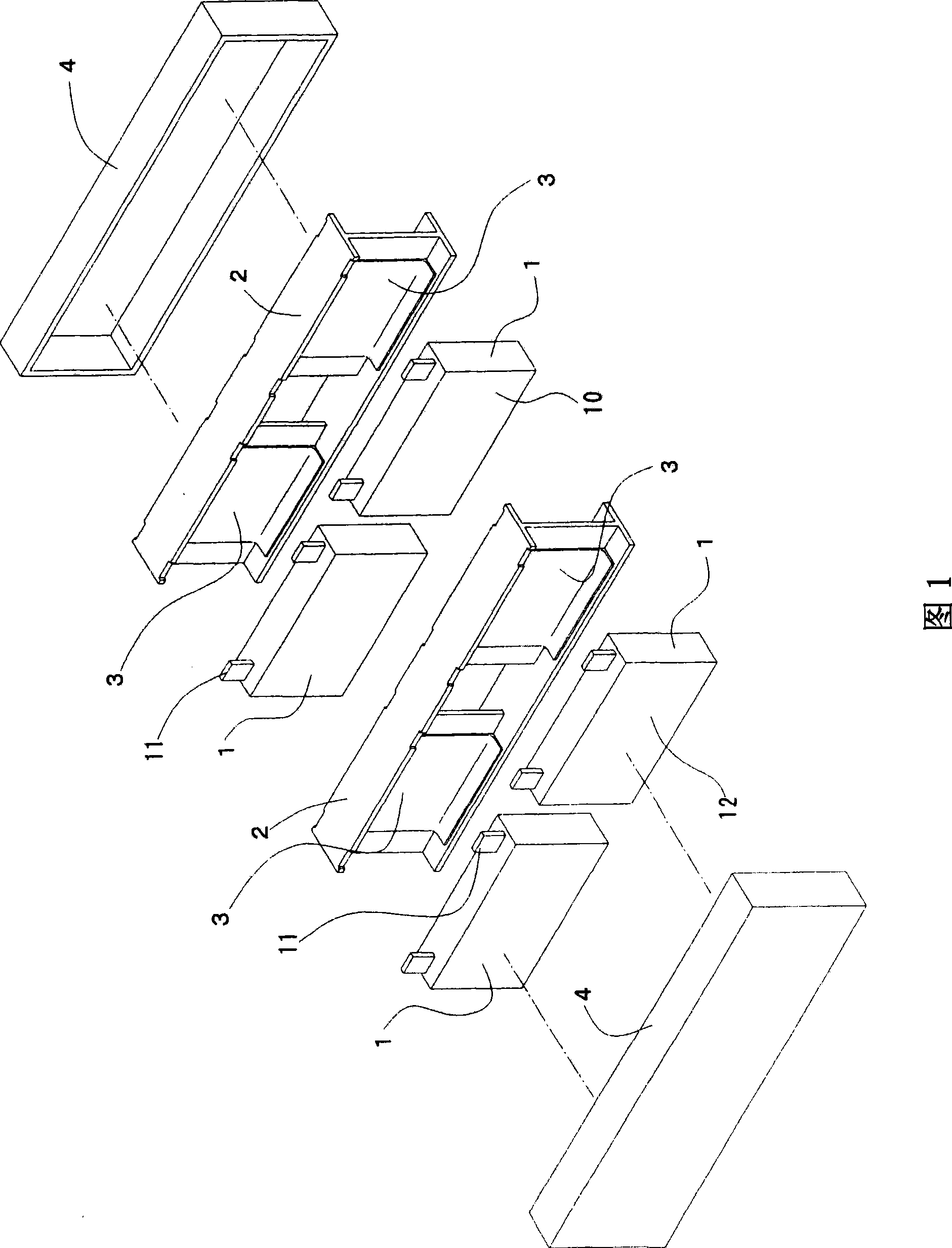

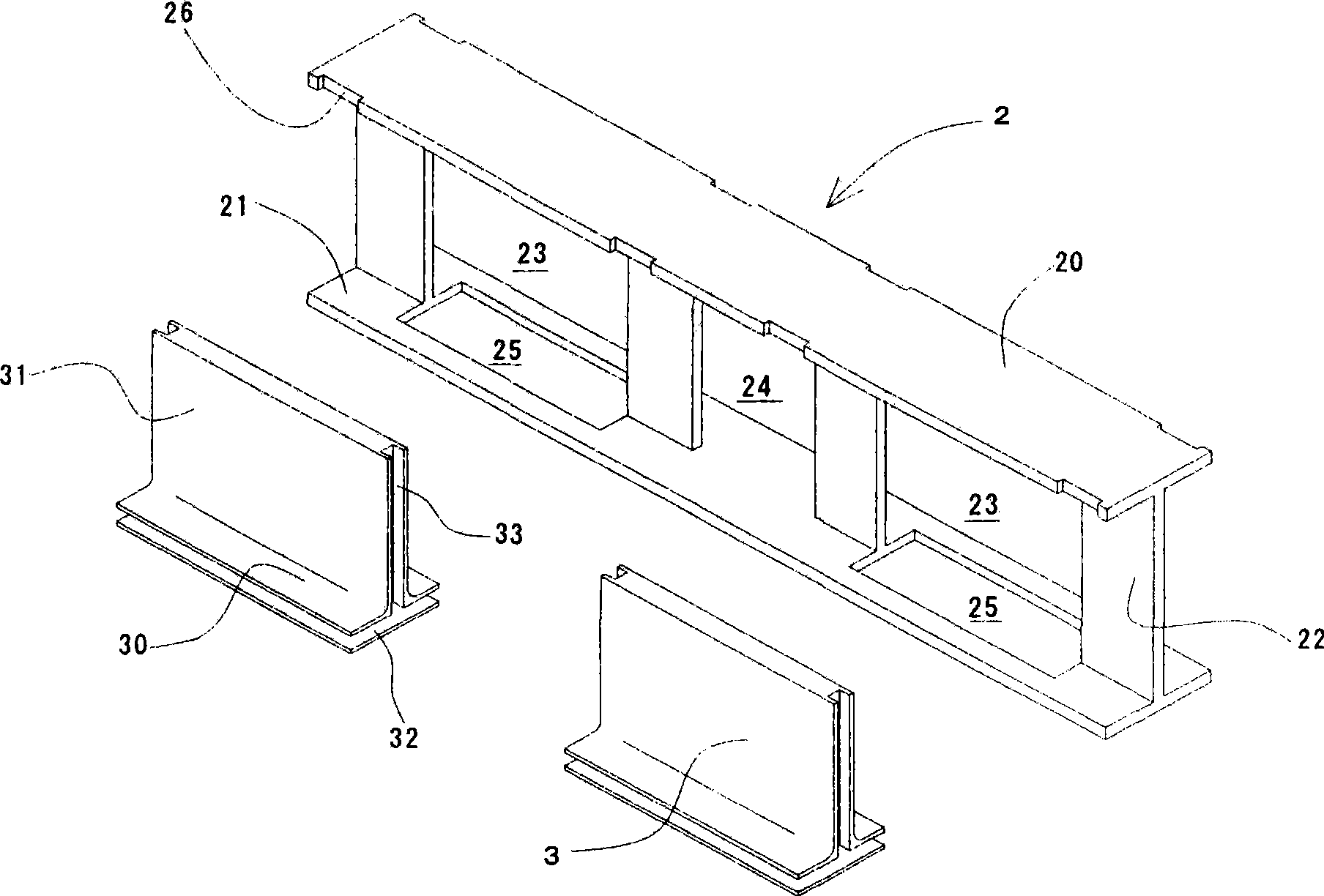

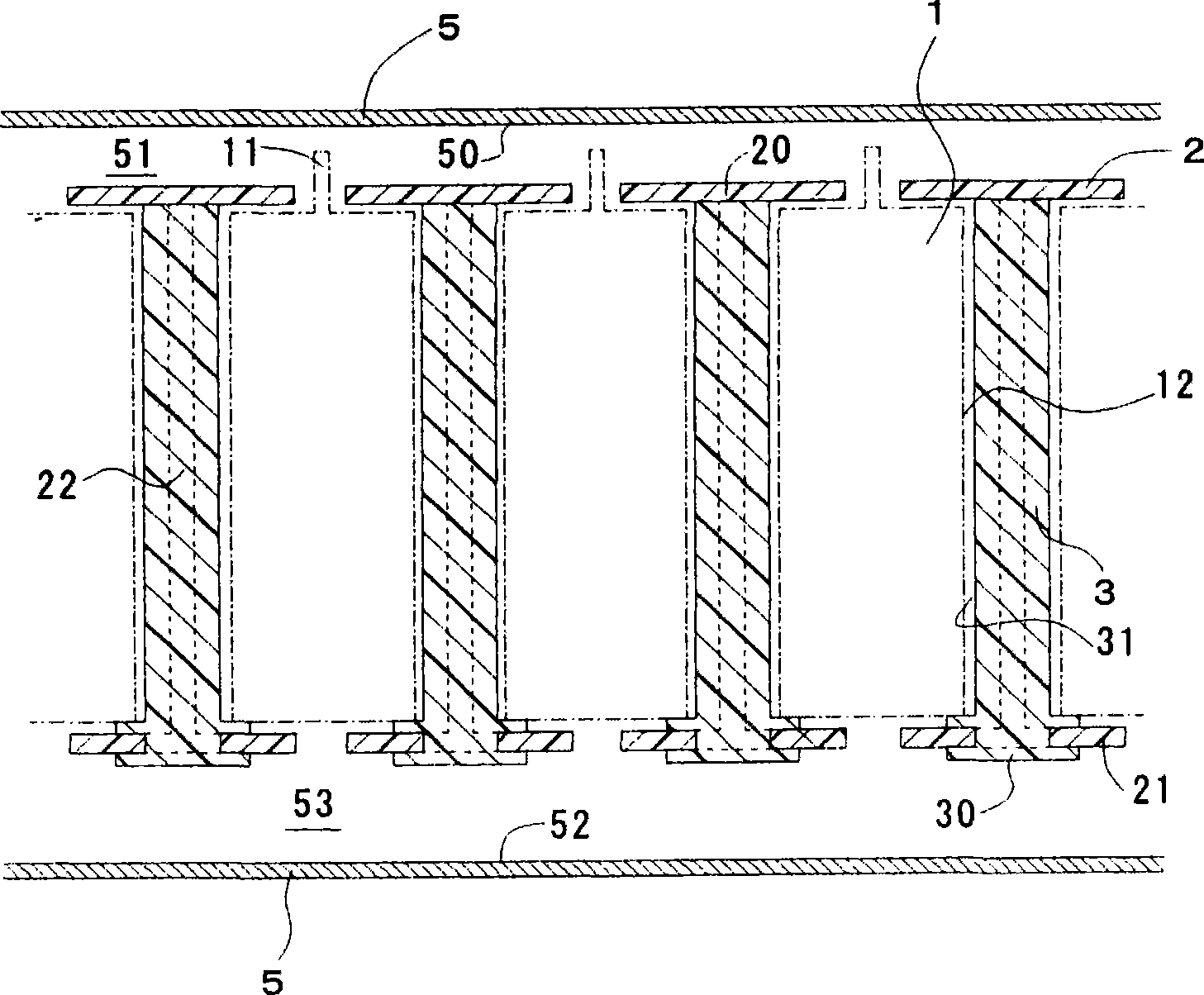

[0044] Fig. 1 is an exploded isometric view illustrating a battery assembly according to a first embodiment of the present invention. The battery assembly according to the first embodiment includes dozens of unit cells 1, separators 2 and heat conducting members 3. The single cell 1 is formed in a rectangular parallelepiped structure, and each has two sides 12 with the largest area. The separator 2 is made of electrically insulating resin. Half of the single cells 1 and the heat-conducting parts 3 are arranged alternately in rows, thereby forming the left battery sub-assembly in the figure. The other half of the single cells 1 and the heat-conducting elements 3 are also arranged alternately in rows to form the right battery sub-assembly in the figure. The formed two rows of battery sub-assemblies—the left and right battery sub-assemblies are arranged parallel to each other. Note that in the two rows of battery subassemblies arranged in parallel with each other, the separator 2 is ...

no. 2 example

[0056] Such as Figure 4 As shown, the battery assembly according to the second embodiment of the present invention includes a heat-conducting member 3 provided with a lug 34 that extends downward from the base 30 into the space 53. Except for this feature, the battery assembly according to the second embodiment is constructed in the same manner as the battery assembly according to the first embodiment.

[0057] The battery assembly according to the second embodiment of the present invention includes a lug 34, which makes the surface area of the base 30 of the heat-conducting member 3 exposed in the space 53 larger. Therefore, the cooling efficiency of the battery assembly according to the second embodiment of the present invention is higher than that of the battery assembly according to the first embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com