Rough element apparatus with variable rotary-out type wind tunnel

A rough element, screw-out technology, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

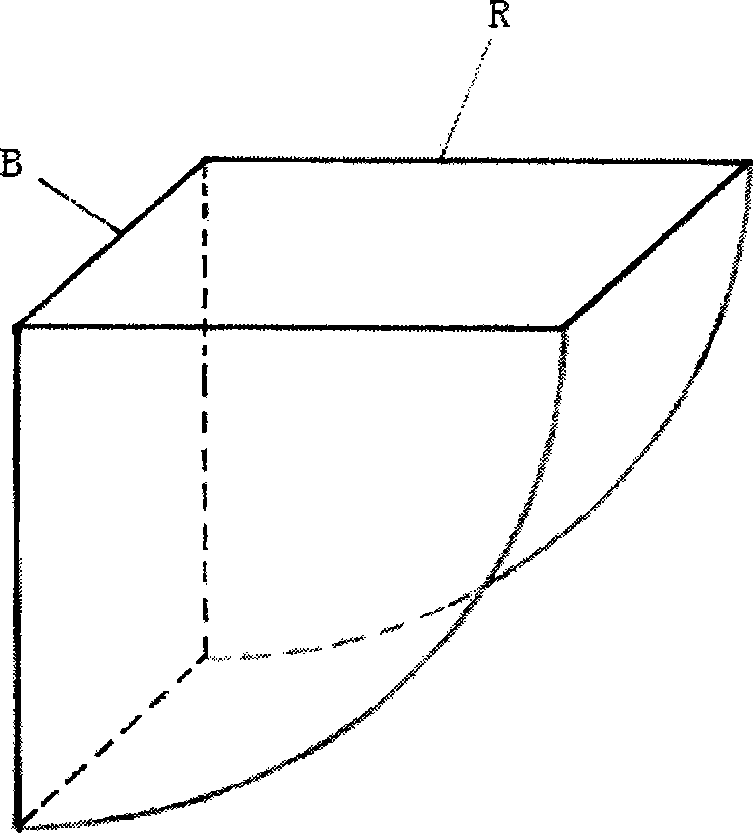

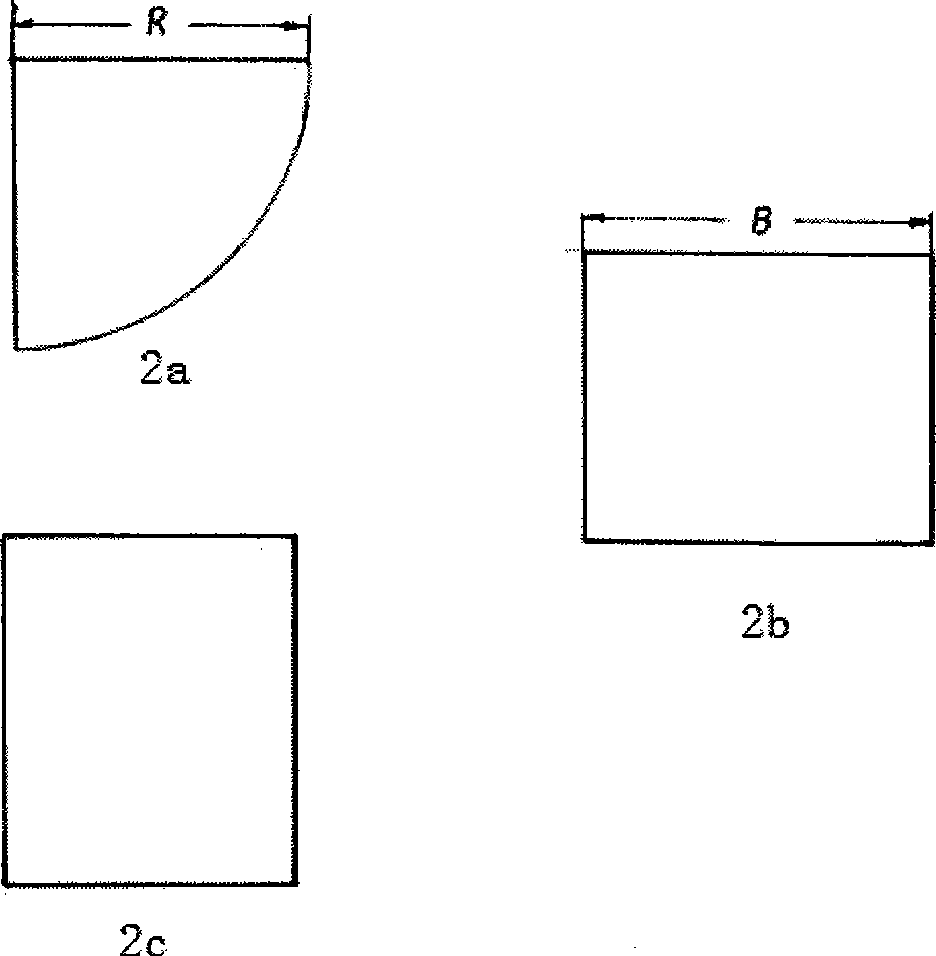

[0013] Example 1: The size of the rough element is as figure 1 , figure 2 and Figure 4 As shown, where the radius is R and the width is B, the distribution map of the rough elements is designed according to the experimental requirements, and a plurality of rough elements that meet the requirements are processed; the perforated plate and the lower plate (or frame) are processed for processing And easy to install, the whole screw-out variable roughness element device can be processed in sections and then butted together. Figure 4 It is a schematic diagram of the distribution of rough elements in the variable rough element device of the swing-out wind tunnel (only four rows are drawn), where R is the radius of the rough elements, B is the width of the rough elements; L is the row spacing, and S is the column spacing; the rough element installation When in the wind tunnel, its column direction is parallel to the wind tunnel axis.

Embodiment 2

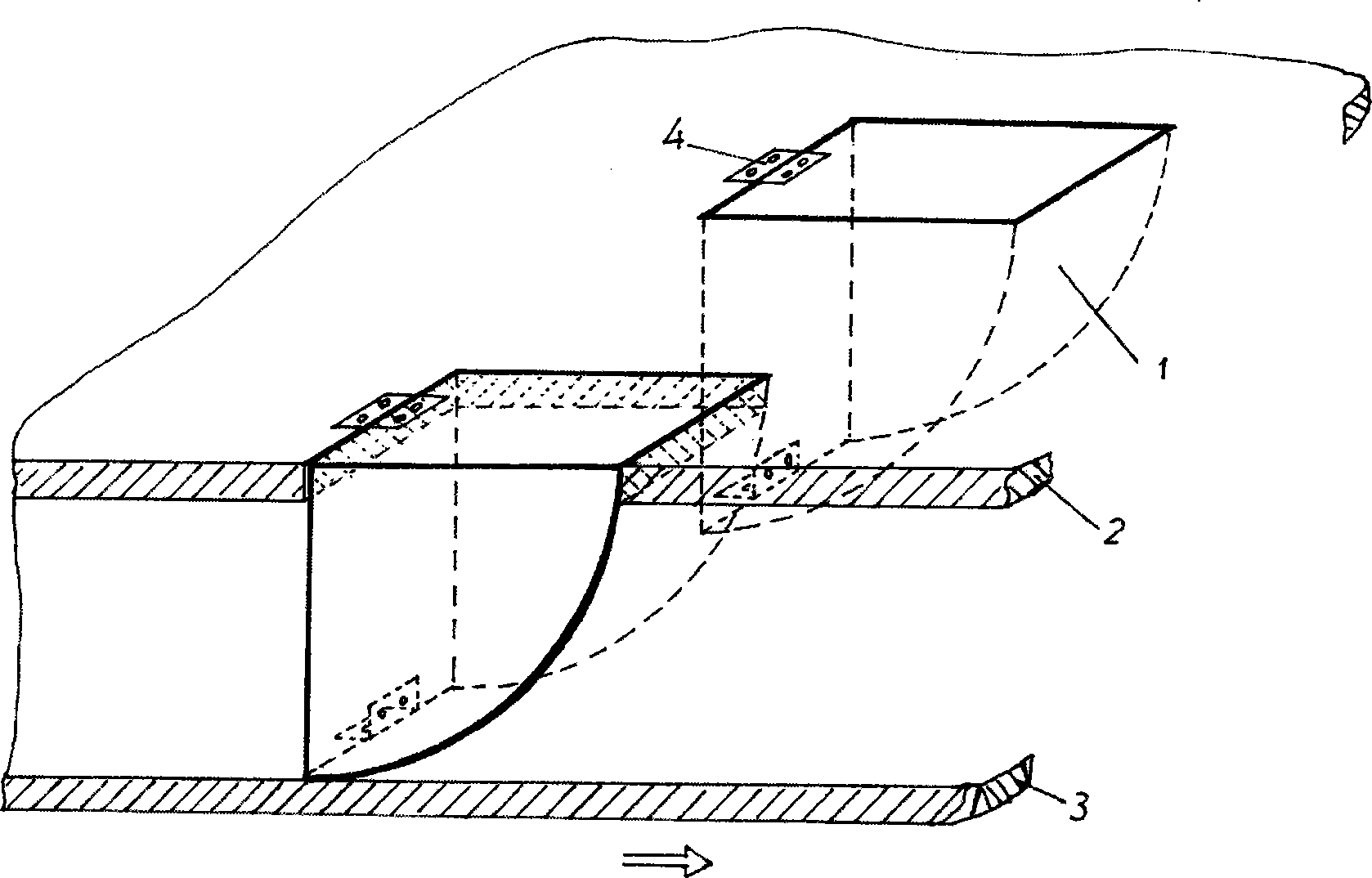

[0014] Example 2: image 3 It is a schematic diagram of the assembly of the variable rough element of the swing-out wind tunnel according to the present invention, wherein, 1 is a single rough element, 2 is a perforated plate, 3 is a lower plate, and 4 is a hinge. The arrow indicates the moving direction of the lower plate. This direction in the hole is usually also the direction of the airflow, but it can also be against the direction of the airflow. like image 3 As shown, the device consists of four main components: multiple rough elements, a perforated plate, a lower plate (or frame) and a hinge. The shape of the rough element is a quarter cylinder section, and the cylinder section is made of various materials such as wood, aluminum, and stainless steel. The purpose of making rough elements into a quarter cylindrical shell is to reduce the weight of each rough element, where the size (radius R, width B) and spacing of each rough element are determined by each wind tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com