Method and apparatus for exchanging nozzle on line

A nozzle, assembly and disassembly technology, which is applied in the field of nozzle replacement, can solve problems such as furnace brick damage, and achieve the effects of prolonging service life, increasing effective gas content and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

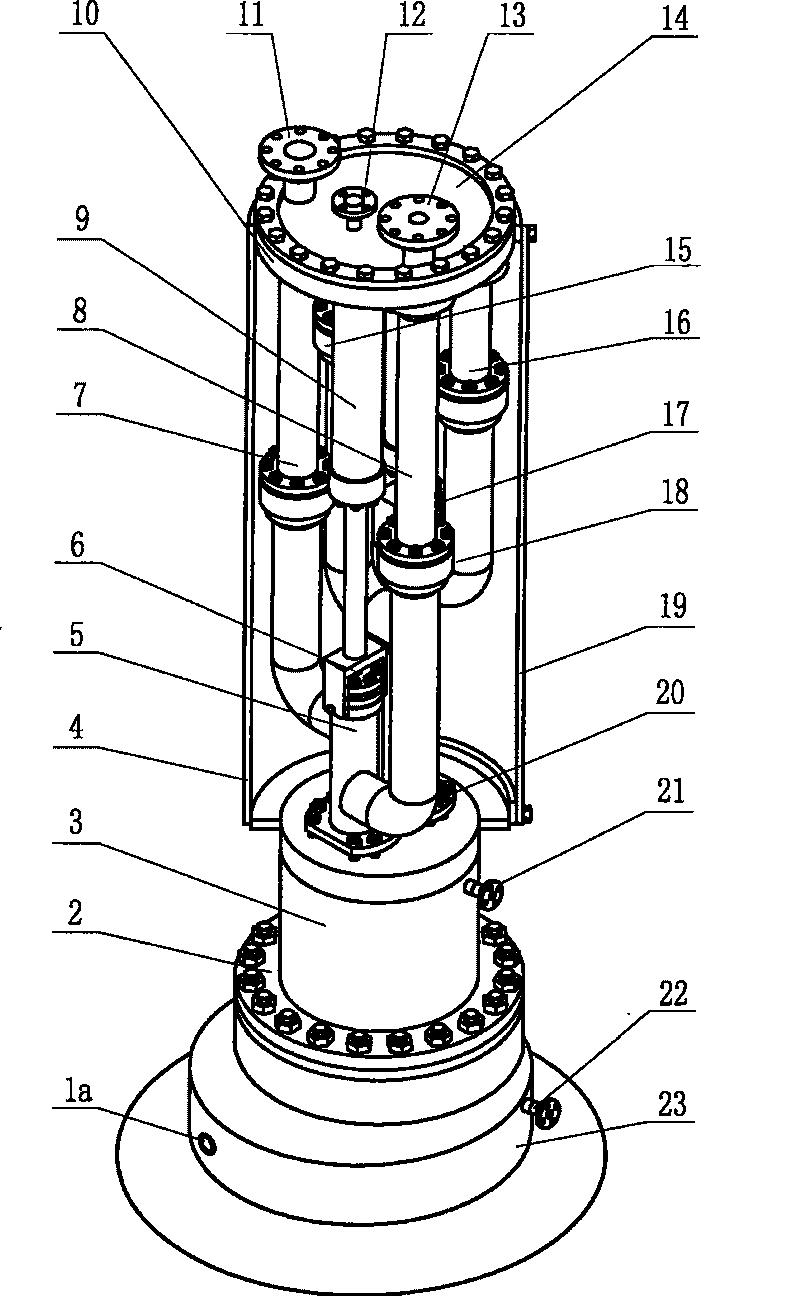

[0073] figure 1 It is a three-dimensional schematic diagram of the main body of the nozzle online replacement device with the outer shell cut off.

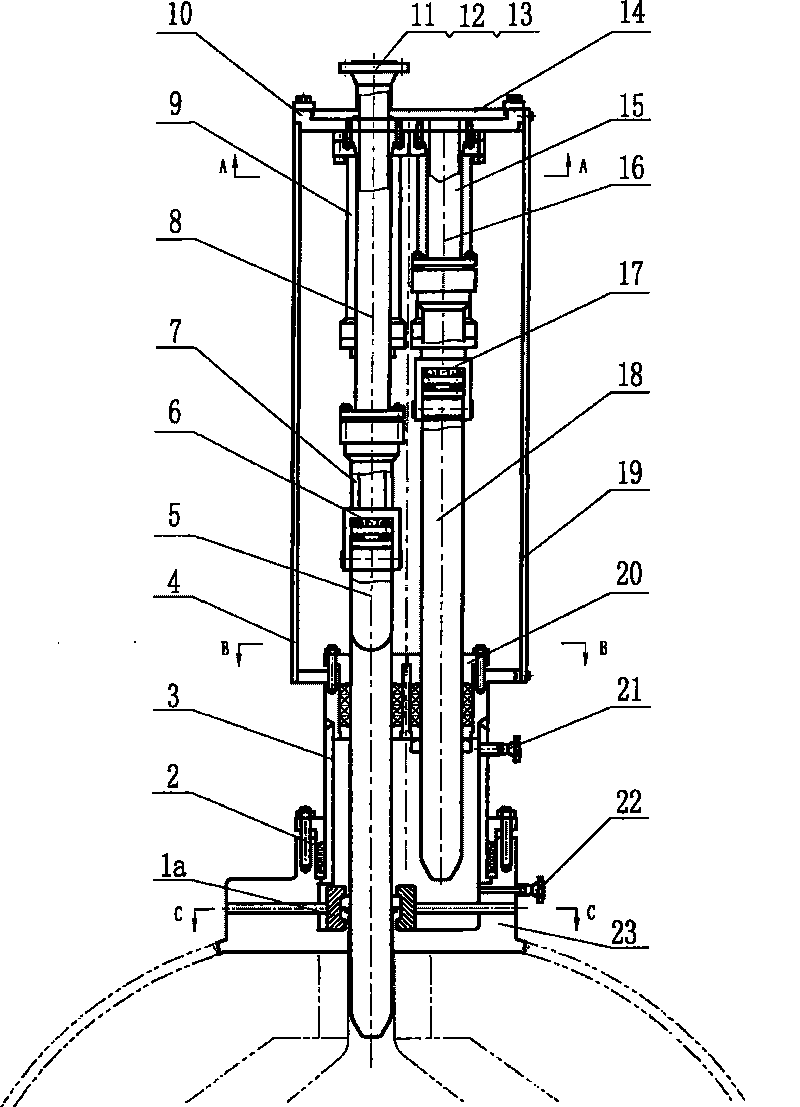

[0074] figure 2 It is a schematic diagram of the main mechanism of a specific embodiment of the online nozzle replacement device.

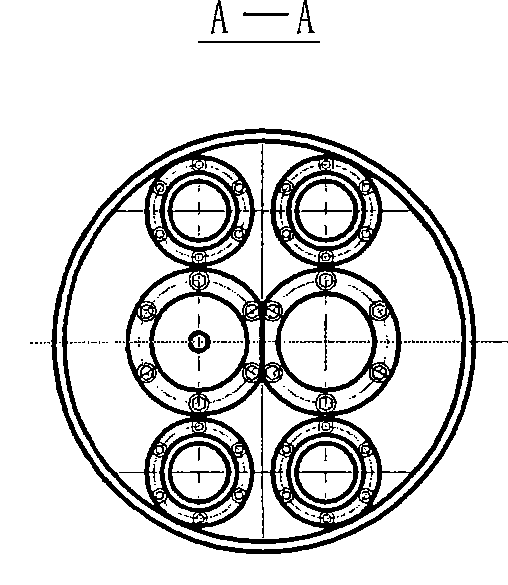

[0075] image 3 yes figure 2 The A-A sectional view of the figure shows the connection position diagram of each telescopic pipe flange and the rear flange of the nozzle driving oil cylinder and the rotary shell of the feed switcher.

[0076] Figure 4 yes figure 2 The B-B sectional view shows the eccentric position of the transition pressure tank and the furnace mouth and the mutual position diagram between the two nozzles.

[0077] Figure 5 yes figure 2 The C-C sectional view of the figure shows the schematic diagram of the clamp type quick assembly and disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com