Method for shortening maize immersion time in cornstarch production process

A production process and corn soaking technology, applied in the field of corn deep processing, can solve the problems of high energy consumption, long soaking time and high production cost, and achieve the effects of low energy consumption, enhanced competitiveness, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

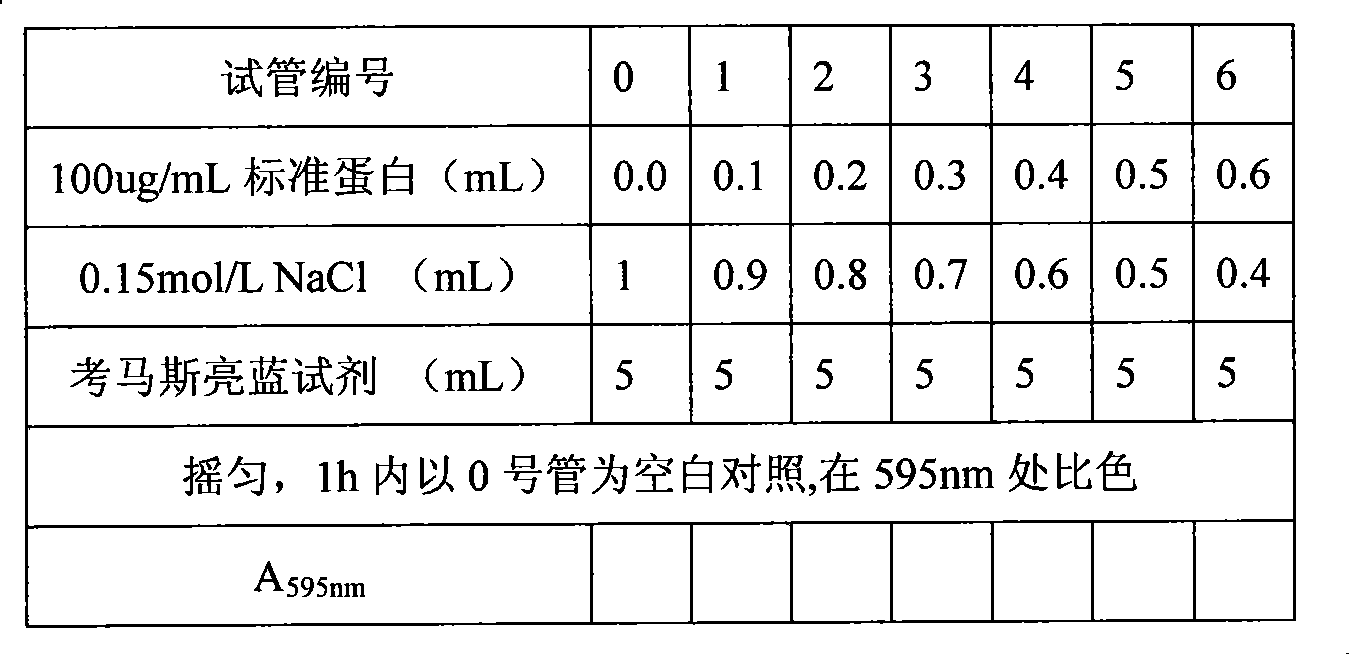

Image

Examples

Embodiment 1

[0029] Select 3.5kg of whole corn with full grains, no insects, no mildew, remove impurities, wash three times, drain overnight, put it into a 10L multifunctional reaction kettle, add water with a mass ratio of 1:1 to corn Finally, add Alkaline protease (Alkalineprotease) produced by Novozymes Biotechnology Co., Ltd. at a ratio of 1200IU / g corn, add cellulase produced by Zhaodong Richeng Enzyme Preparation Co., Ltd. at 20IU / g corn, stir evenly, and adjust the air The compressor keeps the pressure of the reactor at 0.2MPa atmospheric pressure, adjust the steam generator and the cooling device in the reactor to maintain the temperature of the soaking liquid at 45°C, after soaking for 15 hours, remove the pressure, open the lid of the reactor, take out the soaked corn and soak liquid. The moisture content of the corn after soaking was measured to be 43.2%, the dry matter content in the soaking solution was 3.75%, the protein content in the soaking solution was 0.041 mg / mL, and th...

Embodiment 2

[0031] Select 3.5kg of whole corn with full grains, no insects, no mildew, remove impurities, wash three times, drain overnight, put it into a 10L multifunctional reaction kettle, add water with a mass ratio of 1:1 to corn Finally, add the acid protease (Acidprotease) produced by Ningxia Hersbit Biotechnology Co., Ltd. at a ratio of 1000IU / g corn, add cellulase produced by Zhaodong Richeng Enzyme Preparation Co., Ltd. at 20IU / g corn, stir evenly, and adjust the air The compressor keeps the pressure of the reactor at 0.2MPa atmospheric pressure, adjusts the steam generator and the cooling device in the reactor to keep the temperature of the soaking liquid at 45°C, after soaking for 12 hours. Remove the pressure, open the lid of the reactor, and take out the soaked corn and the soaking liquid. The moisture content of the corn after soaking was measured to be 44.5%, the dry matter content in the soaking solution was 3.85%, the protein content in the soaking solution was 0.043mg / m...

Embodiment 3

[0033] Select 3.5kg of whole corn with full grains, no insects, no mildew, remove impurities, wash three times, drain overnight, put it into a 10L multifunctional reaction kettle, add water with a mass ratio of 1:1 to corn Finally, add bromelain (Bromelain) produced by Nanning Pangbo Biological Engineering Co., Ltd. at a ratio of 1200IU / g corn, add cellulase produced by Zhaodong Richeng Enzyme Preparation Co., Ltd. at 20IU / g corn, stir evenly, and adjust the air compression Machine to keep the pressure of the reactor at 0.2MPa atmospheric pressure, adjust the steam generator and the cooling device in the reactor to keep the temperature of the soaking liquid at 45°C, after soaking for 15 hours. Remove the pressure, open the lid of the reactor, and take out the soaked corn and the soaking liquid. The moisture content of the corn after soaking was measured to be 43.3%, the dry matter content in the soaking solution was 3.7%, the protein content in the soaking solution was 0.041mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com