A method of altering the sensitivity and/or selectivity of a chemiresistor sensor array

A resistance sensor and sensitivity technology, applied in the field of sensor arrays, can solve the problems of difficult and high cost of chemical resistor arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

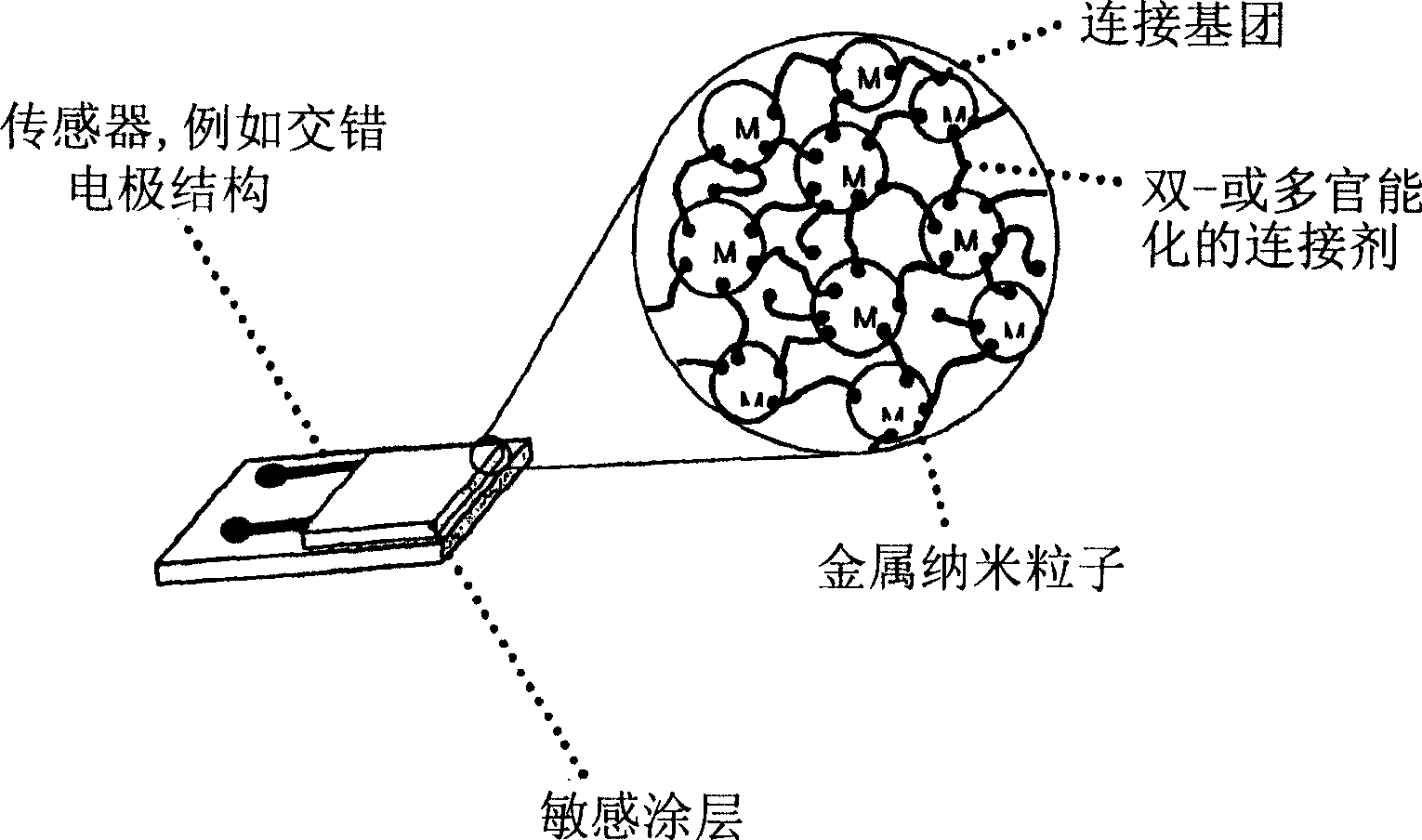

[0063] Among various materials, gold nanoparticles interconnected with organic poly- or dithiols are particularly suitable. These are prepared as described in EP 00 127 149 and EP 05 025 558.7. In the simplest case of interconnecting alkylene dithiols, functionalized SH groups can be oxidized, eg by ozone treatment.

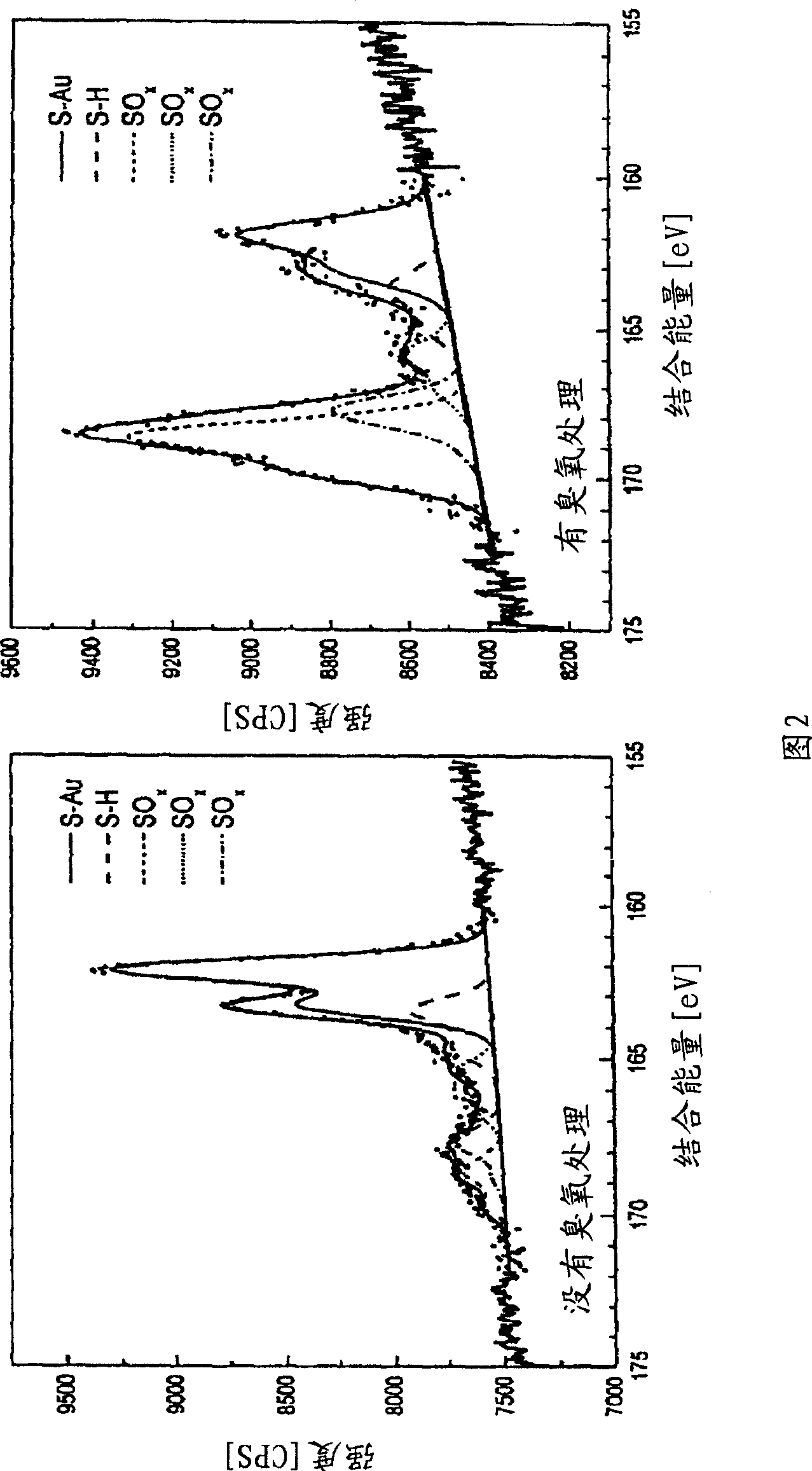

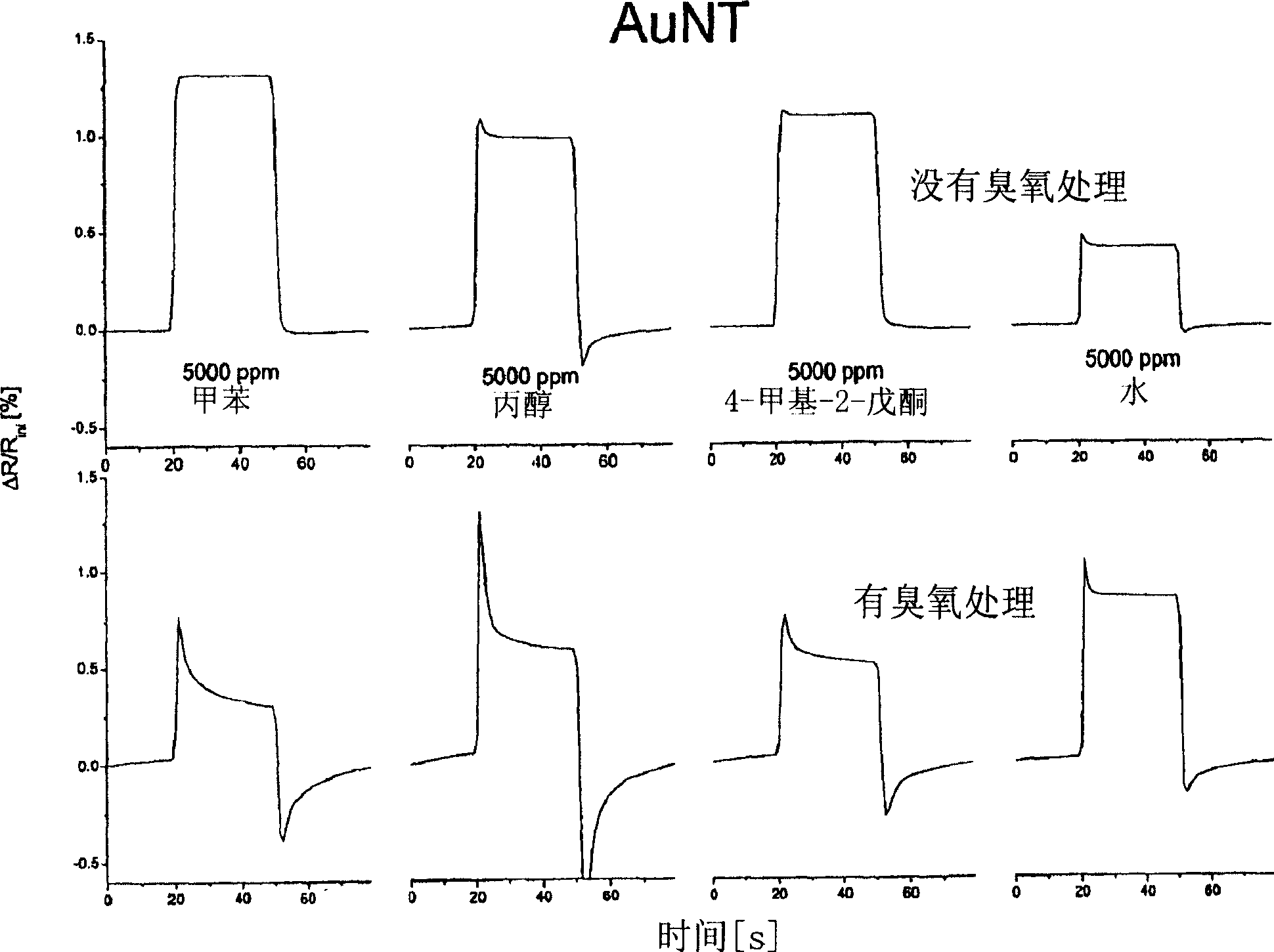

[0064] The X-ray photoelectron spectra (shown in Figure 2) of nonanedithiol-interconnected gold nanoparticles prepared by the layer-by-layer self-assembly method mainly reveal Au-S-R and R-S-H before treatment with ozone and after treatment with ozone Au-SO x (1 min ozone treatment in UVO-Cleaner, model no. 42-220, Jelight Company Inc., CA, USA). Due to this treatment, the sensitivity and selectivity of the sensor changes (compare image 3 ).

[0065] Figure 2 shows sulfur (2p) X-ray photoelectron spectra of chemistor coatings with and without ozone treatment. Ozone treatment is performed by generating ozone in situ.

[0066] As shown in the response traces...

Embodiment 2

[0068] A comparable effect is obtained by oxidative treatment of the sensor by soaking the chemi-resistor in, for example, a 5% hydrogen peroxide solution for 1-60 seconds.

Embodiment 3

[0070] For a single sensor device, this post-fabrication process allows selective conditioning of the sensor at a location different from where the sensor was fabricated and at a time significantly later than the original fabrication. This means that the consumer or the technician or any end user can adjust the sensor to specific needs at the end user if possible (cf. Figure 4 ).

[0071] Conditioning is facilitated by the use of special treatment kits that include different chemicals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com