Contact tip construction of non-excited tapping switch

A technology of tap changer and contact, which is applied in the direction of electric switch, electrical components, prior contact arrangements, etc. It can solve the problems of application limitation of contact structure, increase of running stroke, poor stability, etc., and achieve switch gear shifting operation torque light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

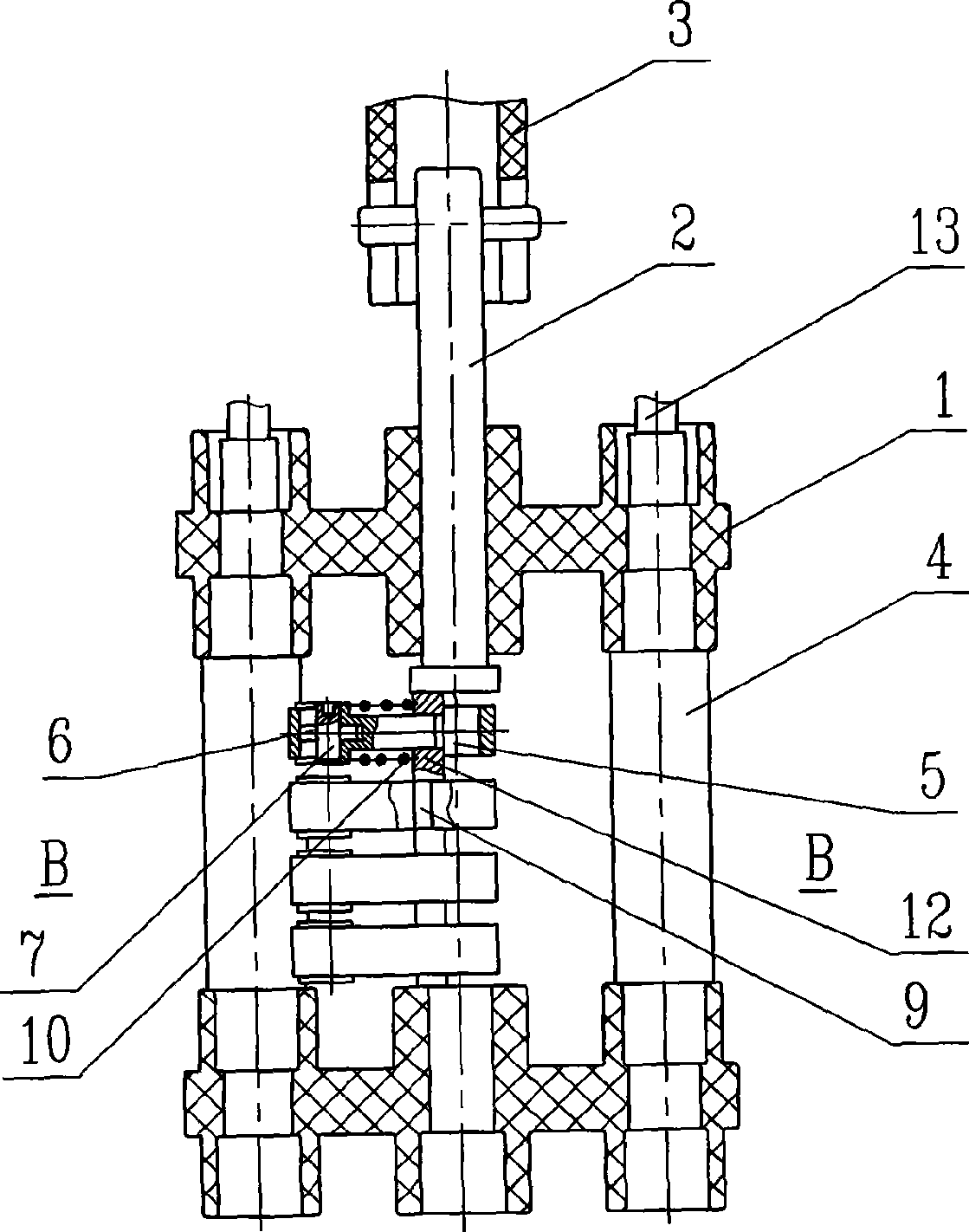

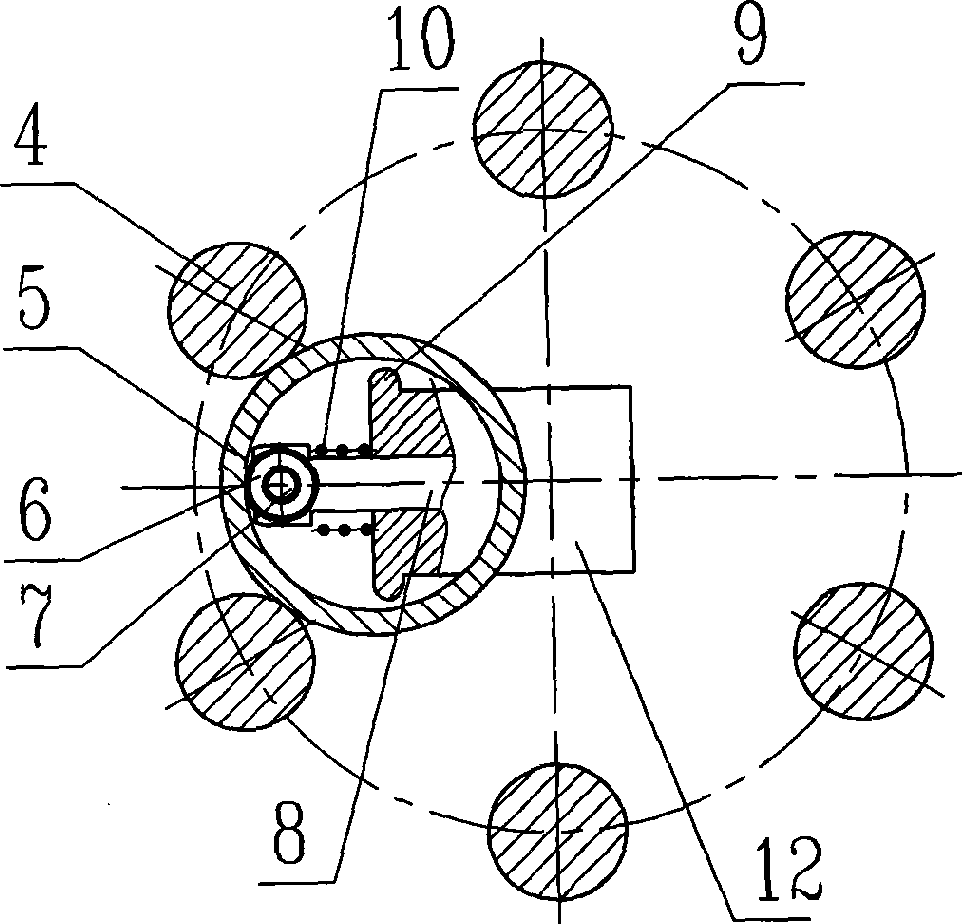

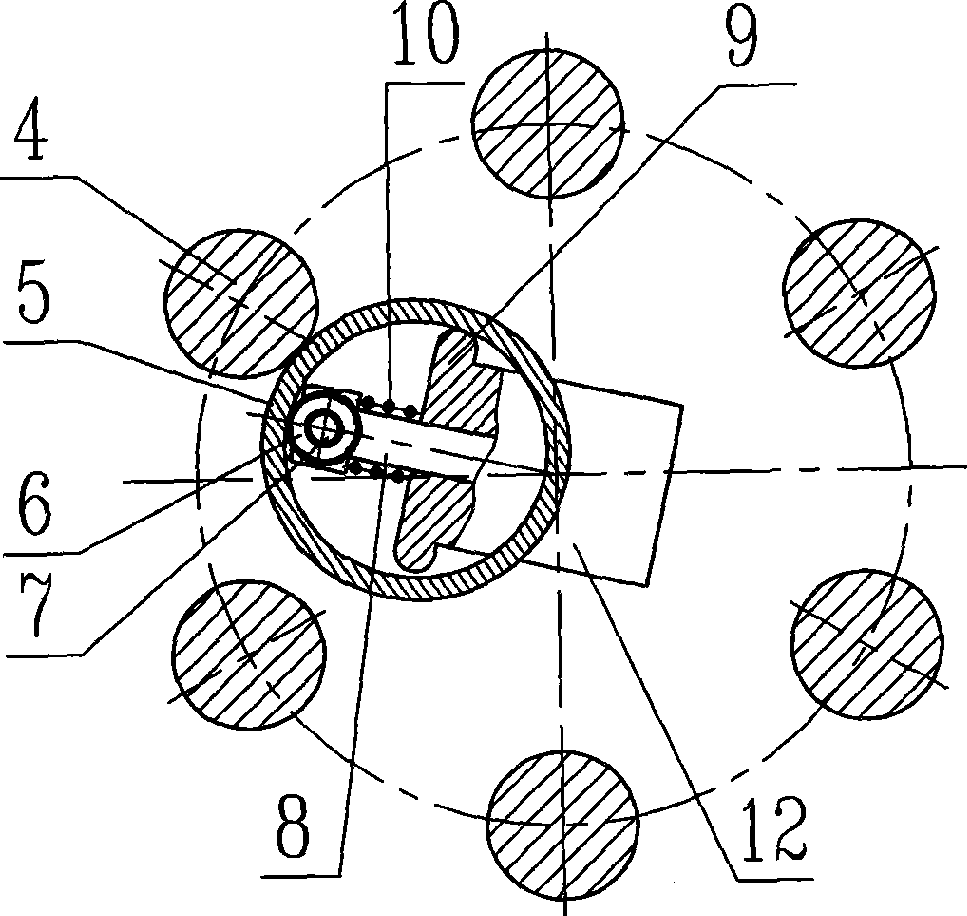

[0015] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0016] An example of the present invention is figure 1 , 2 . As shown in 3, it is a single-phase five-speed non-excitation drum-shaped tap changer, including switch supports 1 arranged up and down, and a main shaft 2 is installed between the two switch supports, and the upper end of the main shaft is connected with the switch operating mechanism 3 , an eccentric support piece 12 is installed on the main shaft, and a columnar fixed contact 4 is arranged at intervals along the circumferential direction between the two switch supports. The upper end of the columnar fixed contact is connected with a lead wire 13 or a terminal, and two adjacent columnar fixed contacts There is a ring-shaped moving contact 5 across the head, and the ring-shaped moving contact is set on the support and configured with the radial sliding pin 8 and the spring 10 installed on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com