Ore-washing ore processing equipment

A mineral concentrator and ore washing technology, which is applied in the field of mining machinery, can solve the problems of large water consumption and achieve the effects of energy saving, high production efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

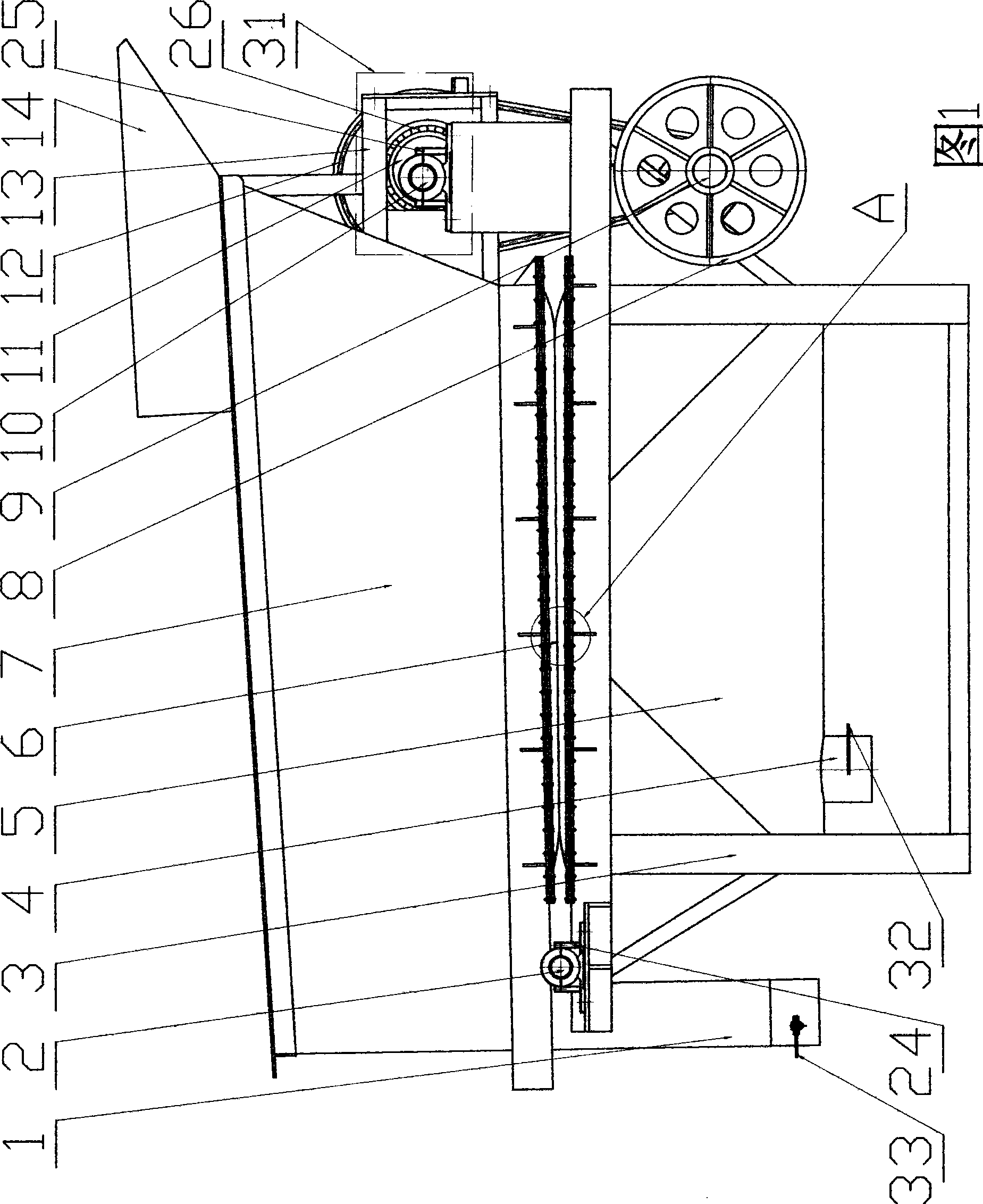

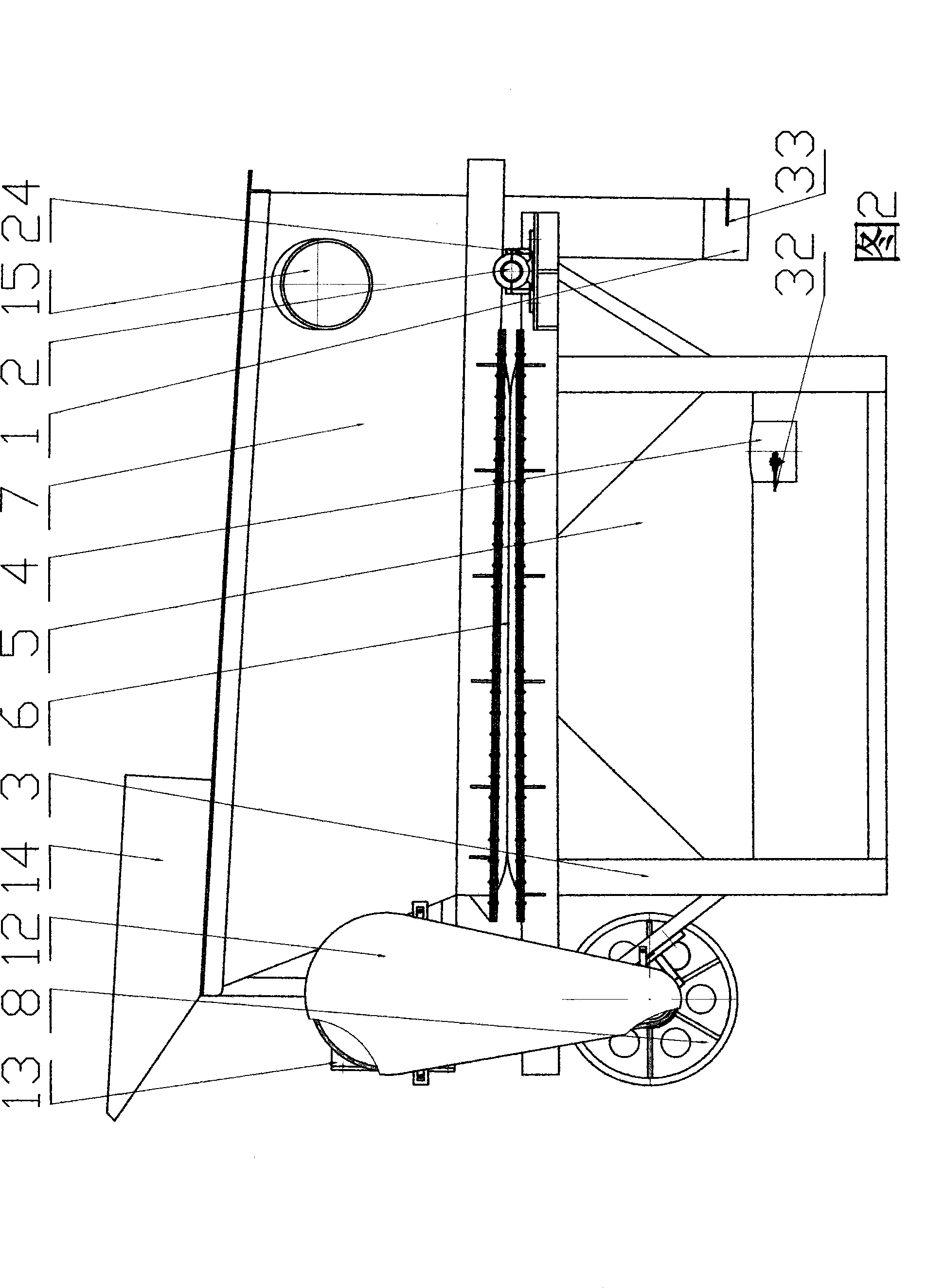

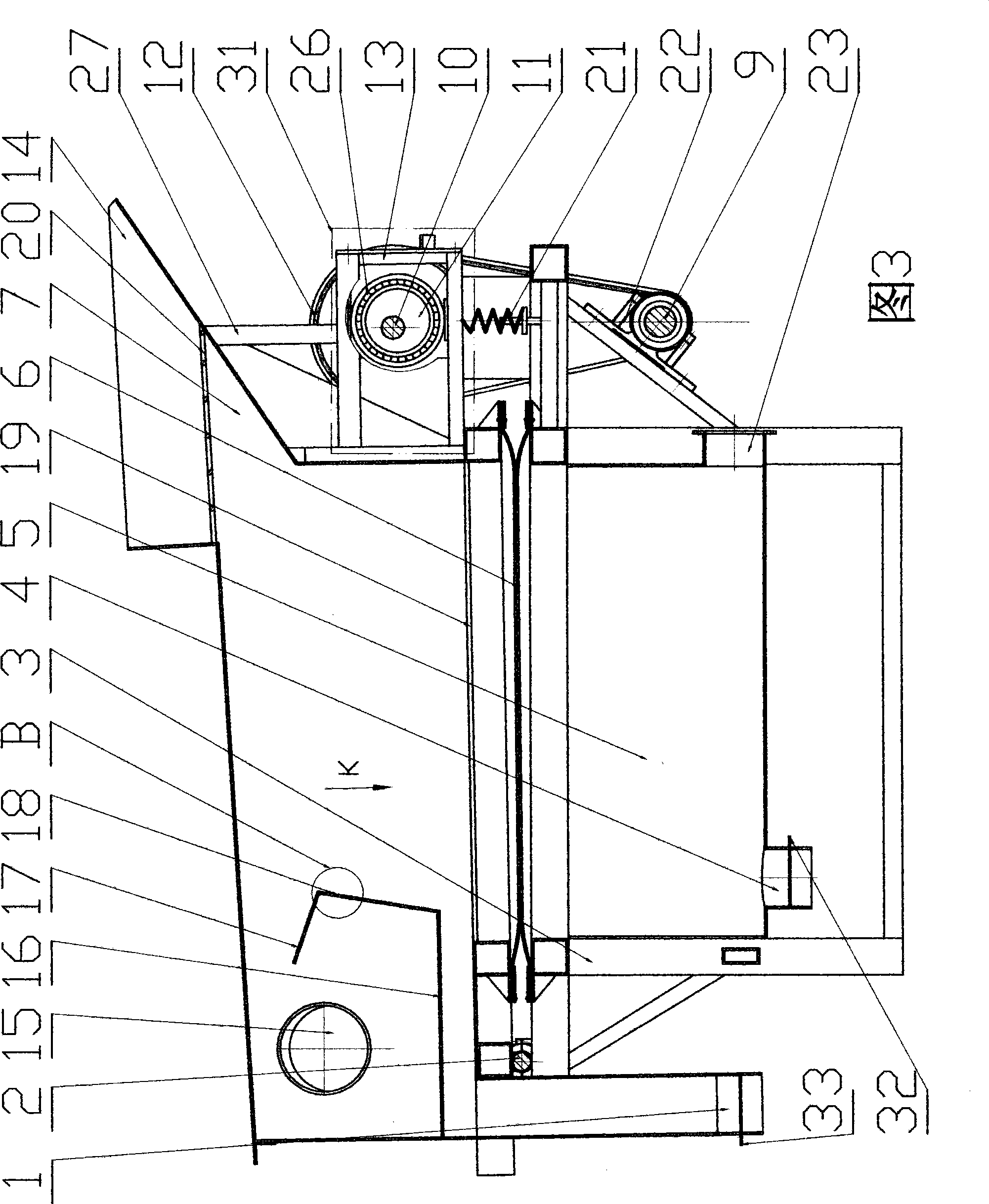

[0025] The present invention will be further described below in conjunction with the drawings and embodiments.

[0026] This embodiment is composed of a frame 3, a water tank 5, a movable ore washing and beneficiation tank 7, a power transmission device 12, a flexible connection device 6, two vibration devices 31 and two energy storage devices 21.

[0027] The frame 3 is a frame-shaped frame, and the water tank 5 is installed in the middle. A fine ore discharge hopper 4 is provided at the lower left of the water tank 5, a fine ore discharge hopper valve 32 is installed at the lower part of the fine ore discharge hopper 4, and a water tank inlet 23 is provided at the lower right side of the water tank 5. The front and rear sides of the upper left part of the frame 3 are respectively equipped with pin bearing seats 24, and the front and rear sides of the right middle part are equipped with brackets. The power input shaft 9 is installed on the bracket, and the front and rear sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com