Method and system for producing a dental prosthesis

A technology for dentures and tooth frames, which is applied in the field of producing dentures including or including tooth frames and dental decorations, and can solve problems such as casting flash, casting defects, and burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

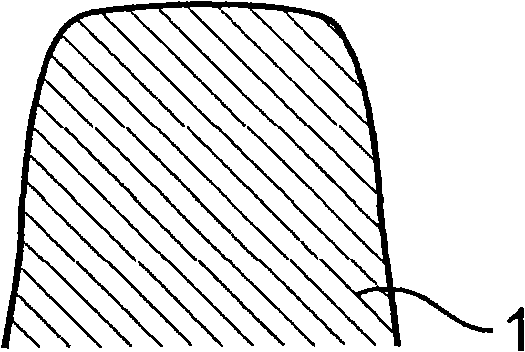

[0080] figure 1 A dental post or model 1 of a dental post is shown. Of particular importance here is the geometrical data of the outer contour of the post, the frame (see figure 2 ) to match the inner contour.

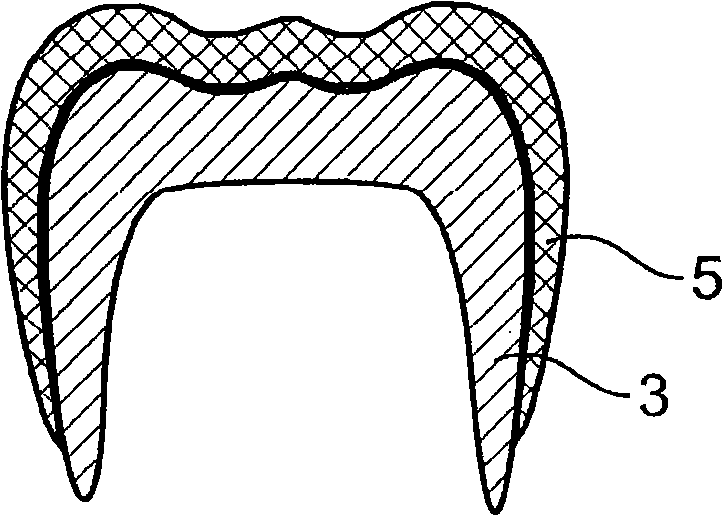

[0081] figure 2 A dental bracket 3 with an inner contour adapted to the outer contour of the dental post 1 is shown. The tooth frame 3 in turn has an inner contour of the dental veneer which must be defined to match its outer contour.

[0082] image 3 A first embodiment of a dental bracket 3 is shown, on top of which a model 5 of a dental veneer is positioned. The model 5 is directly generated on the dental frame 3 itself based on the three-dimensional geometric data of the dental frame 3, or is formed separately, and has an outer contour corresponding to the intended denture.

[0083] Figure 4 A second embodiment of the combination of a dental frame 3 and a model is shown. The model consists of two model parts 5a, 5b which are produced separately from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com