Oil well with rod pressure test operation method

A technology of pressure testing and rods, which is applied in earthwork drilling, wellbore/well components, measurement, etc. It can solve problems such as pressure testing difficulties, achieve convenient operation, improve construction progress, and improve the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiment of the sucker rod hanger 12: take the sucker rod hanger 12 with the outer diameter of the suspension body 3 as 47mm, the upper internal thread screw thread 2 as 25.4mm, and the lower internal thread sucker rod buckle 4 as 22.2mm as an example , the present invention will be described in further detail.

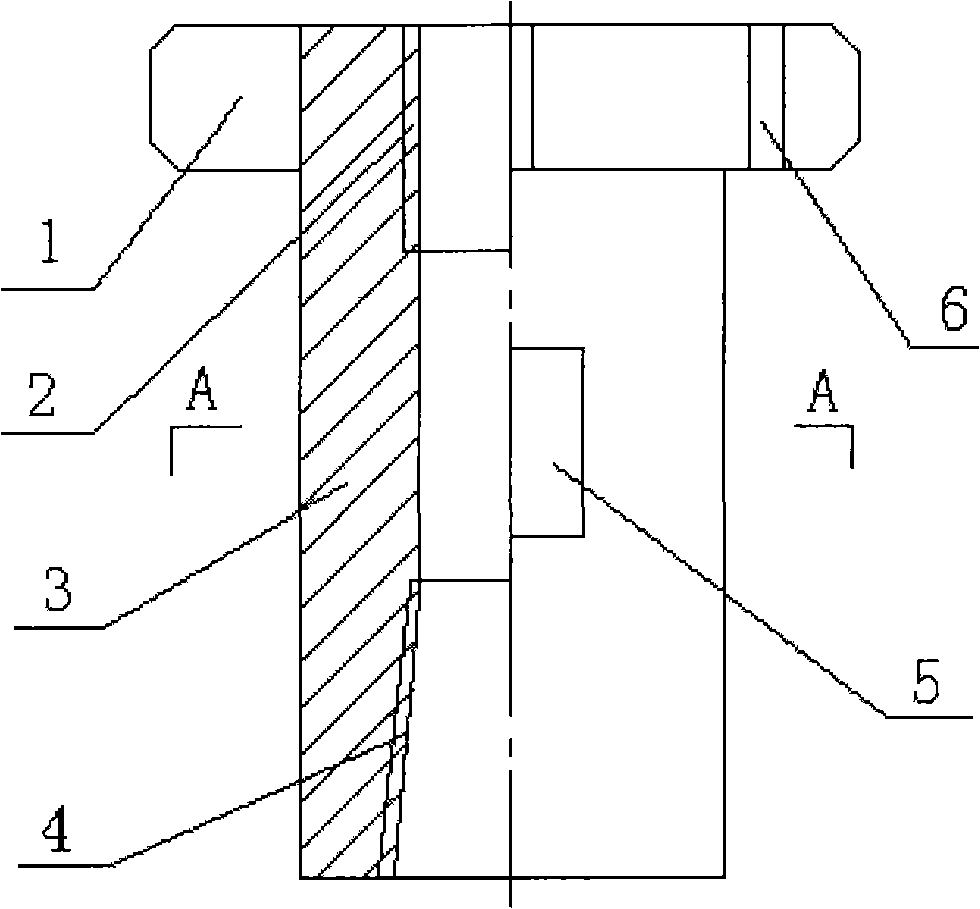

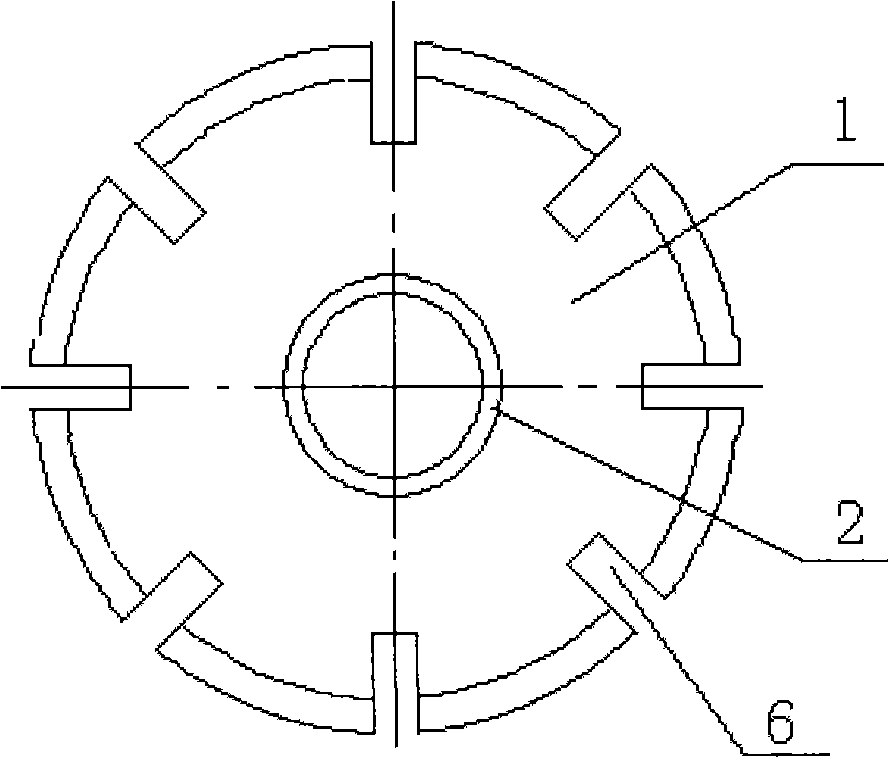

[0032] refer to figure 1 . The sucker rod hanger 12 of the present invention is composed of a base plate 1 and a suspension body 3 . The suspension body 3 is cylindrical, with an outer diameter of 47mm and a length of 240mm. The suspension body 3 has a central hole. The upper end of the center hole has an internal screw thread 2 with a specification of 25.4mm, which can be connected to a 25.4mm sucker rod nipple. The lower end of the center hole has an internal thread sucker rod buckle 4, and the specification is 22.2mm, which can be connected to a 22.2mm sucker rod.

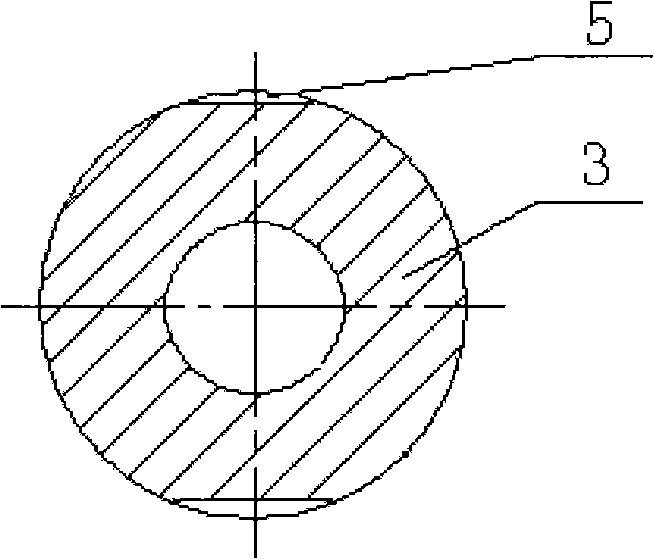

[0033] refer to image 3 . There is a symmetrical plane 5 on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com