Vehicle side-wall inner-plate

A side wall inner panel and automobile technology, applied to vehicle components, upper structure, upper structure sub-assembly, etc., can solve the problems of insufficient support, insufficient strength, and affecting the service life of the body, so as to prevent glue loss and improve torsional strength , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail;

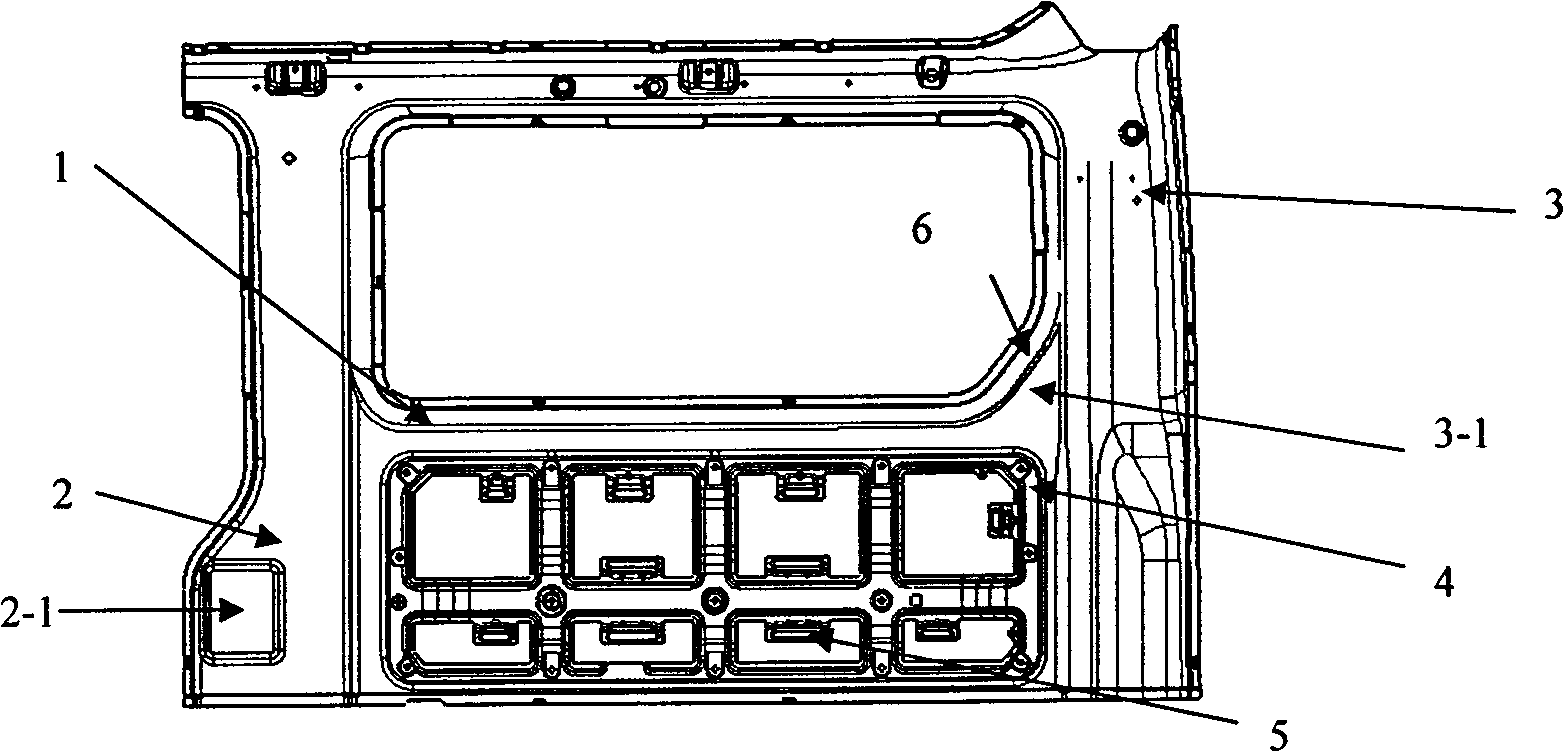

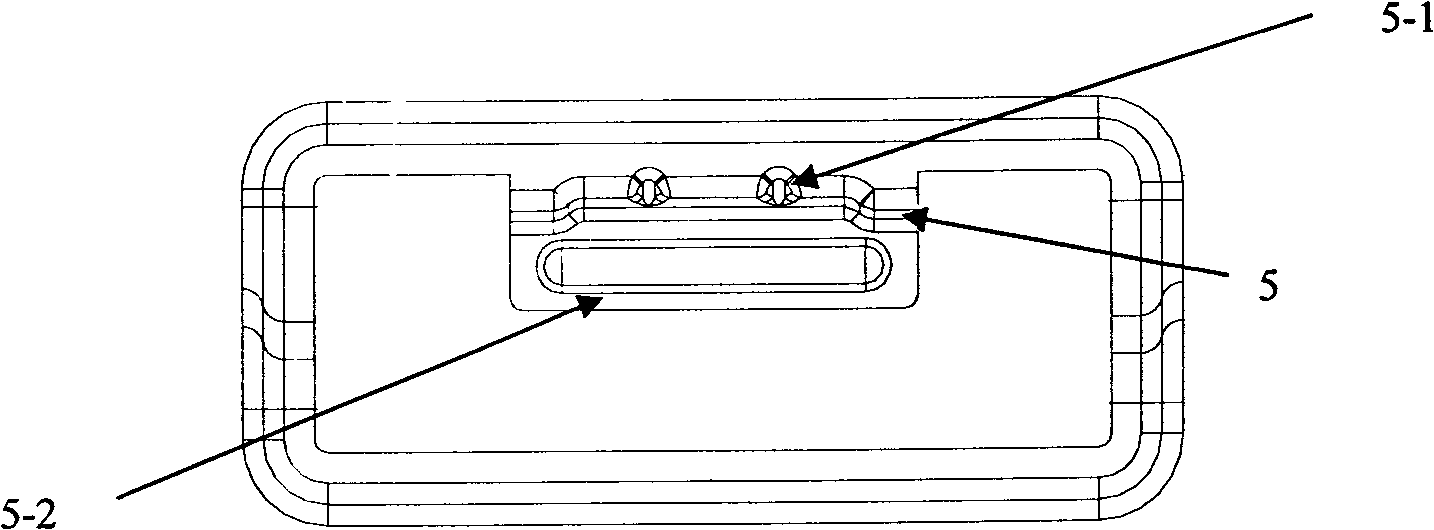

[0017] See figure 1 , figure 2 , the automobile side wall inner panel of the present invention, the plate body 1 is approximately rectangular, the front part of the plate body 1 is a C-pillar 2, and the lower end of the C-pillar 2 is provided with a groove 2-1, which can improve the torsional strength of the vehicle. The rear part of the plate body 1 is the D-pillar 3, and the middle part 3-1 of the D-pillar is in the shape of a trumpet, which not only plays a transitional role, but also reduces stress concentration. The middle and upper part of the plate body is the rear side window frame 6, which is in an inverted trapezoidal shape, and its lower part is narrower near the middle part 3-1 of the D-pillar, which is an inward bevel, which can avoid cracking of the side wall outer panel. A plurality of weight-reducing holes 4 are evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com