Mixed flow fan

A mixed-flow fan and air duct technology, which is applied in the direction of ventilation systems, mechanical equipment, machines/engines, etc., can solve the problems of reduced fan life, corona hazards, overheating, etc., and achieve the effect of reducing vibration and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The first embodiment of the present invention provides a mixed flow fan suitable for heat dissipation of locomotive inverters. It should be clear that the mixed flow fan can also be used in other similar occasions.

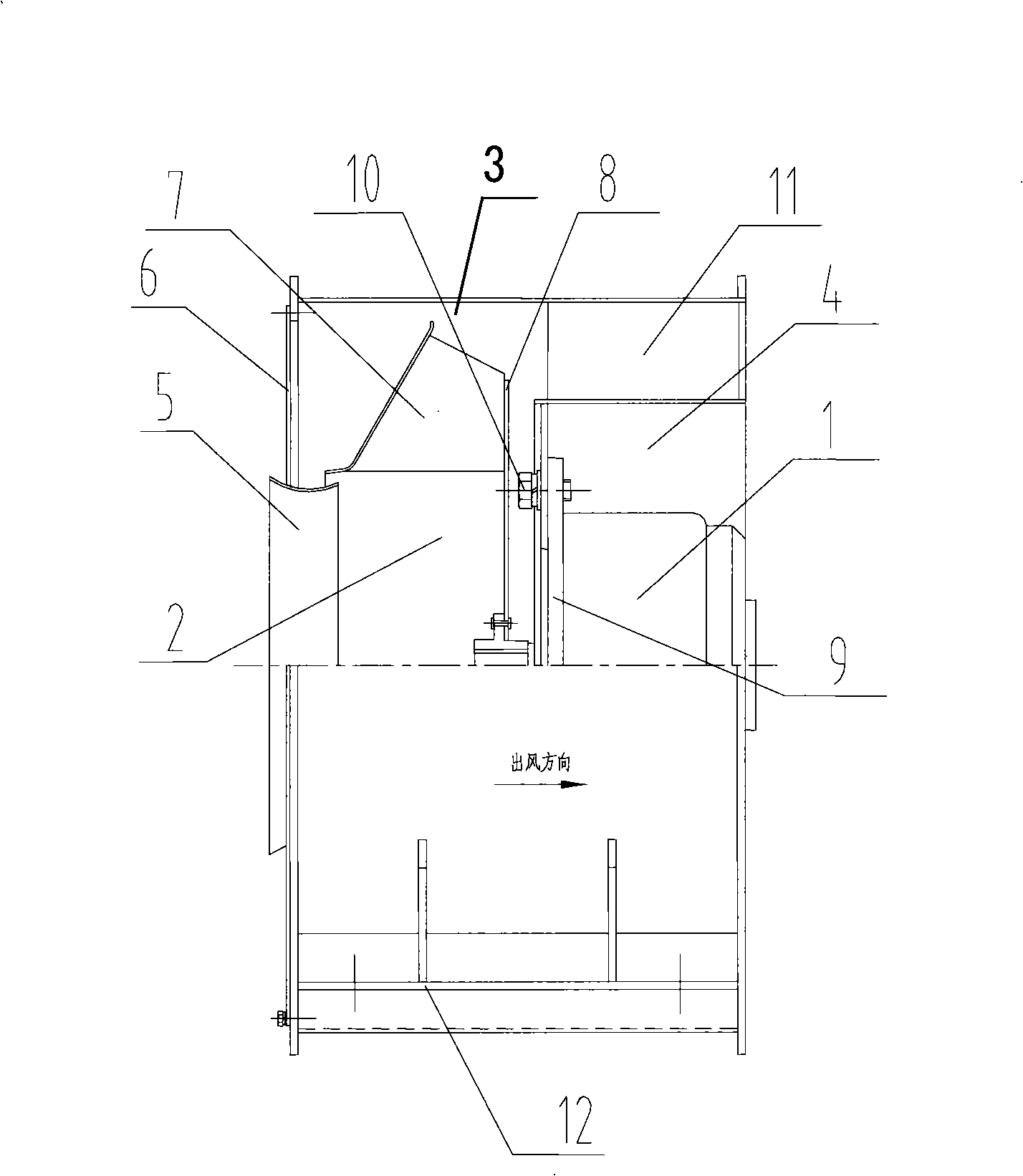

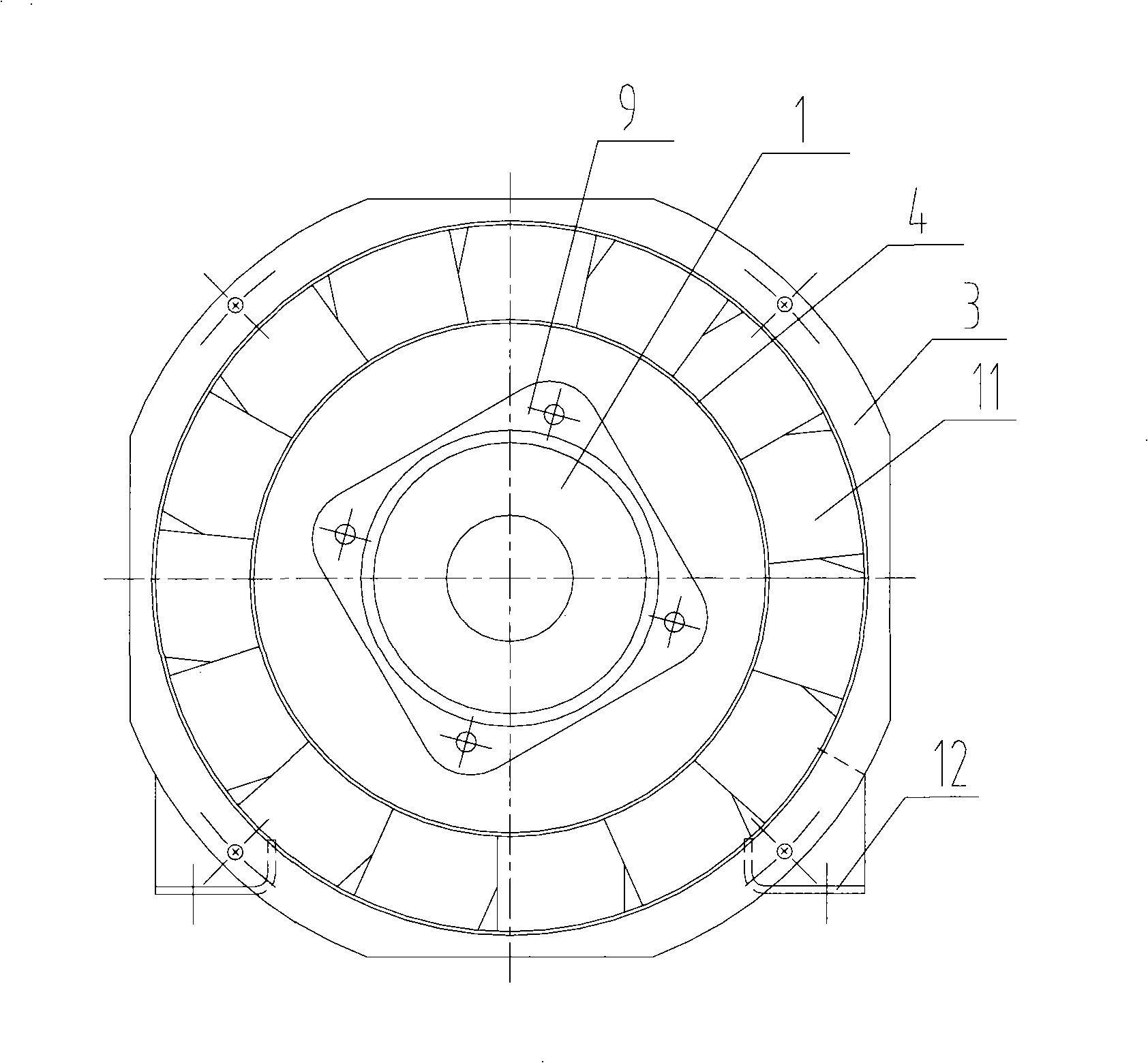

[0036] Please see figure 1 , which is a half-sectional view of the left side of the mixed-flow fan provided by the first embodiment of the present invention. and see also figure 2 , the figure is the front view of the mixed flow fan. The front view direction of the above-mentioned views refers to the direction of viewing the fan from the fan outlet side along the fan axis.

[0037] It can be seen from the figure that the mixed-flow fan includes a drive motor 1 , an impeller 2 , an air cylinder 3 , a guide vane cylinder 4 and guide vanes 11 .

[0038]Wherein, both the air cylinder 3 and the guide vane cylinder 4 are cylindrical, and the diameter and length of the air cylinder 3 are larger than the guide vane cylinder 4 . A plurality of arc-shaped guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com