Filling device of filling machine

A filling device and filling machine technology, which is applied in the field of filling devices of filling machines, can solve problems such as product quality affecting sealing yield, inaccurate quantification, and incomplete cleaning, so as to improve matching accuracy and eliminate waste of raw materials , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

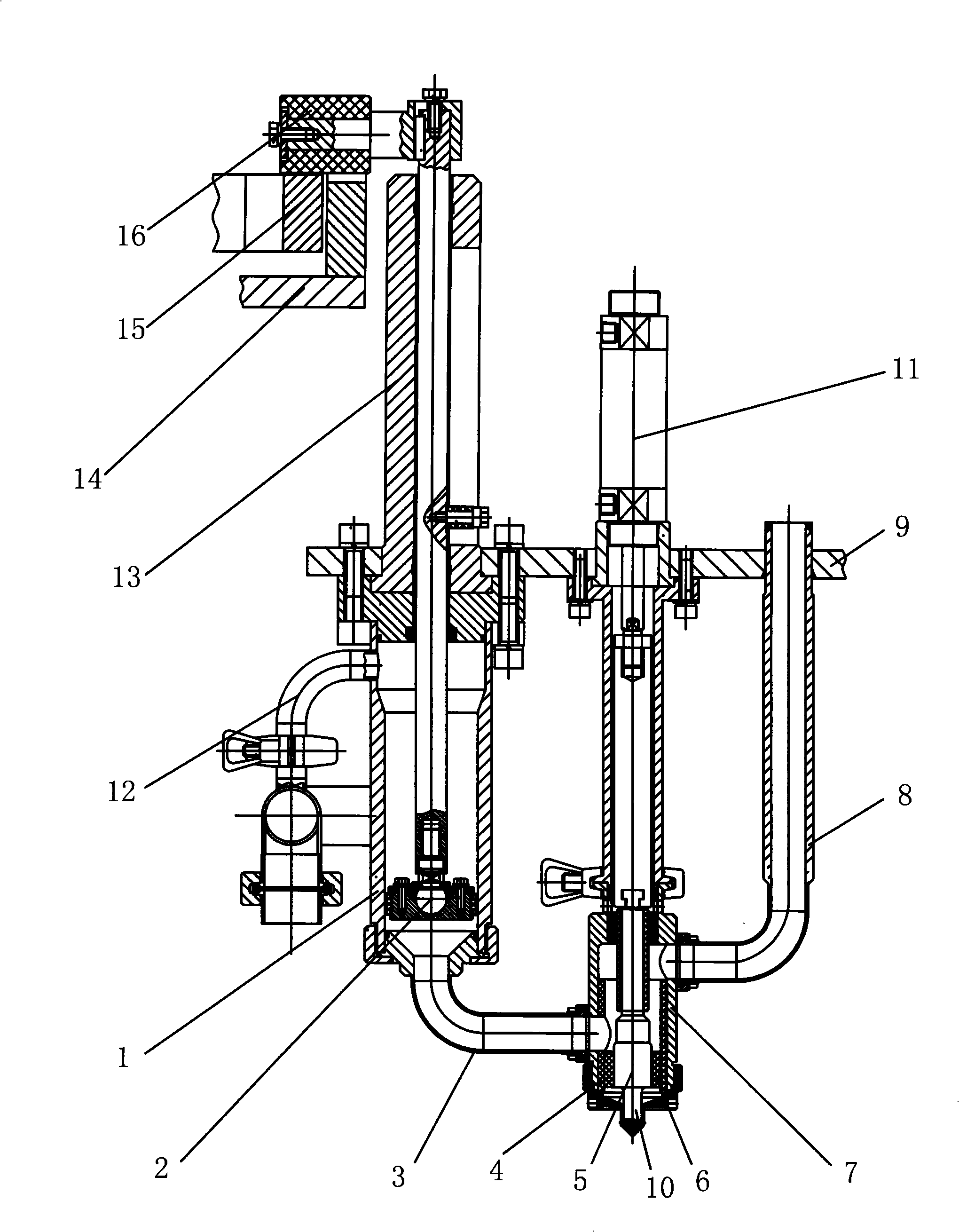

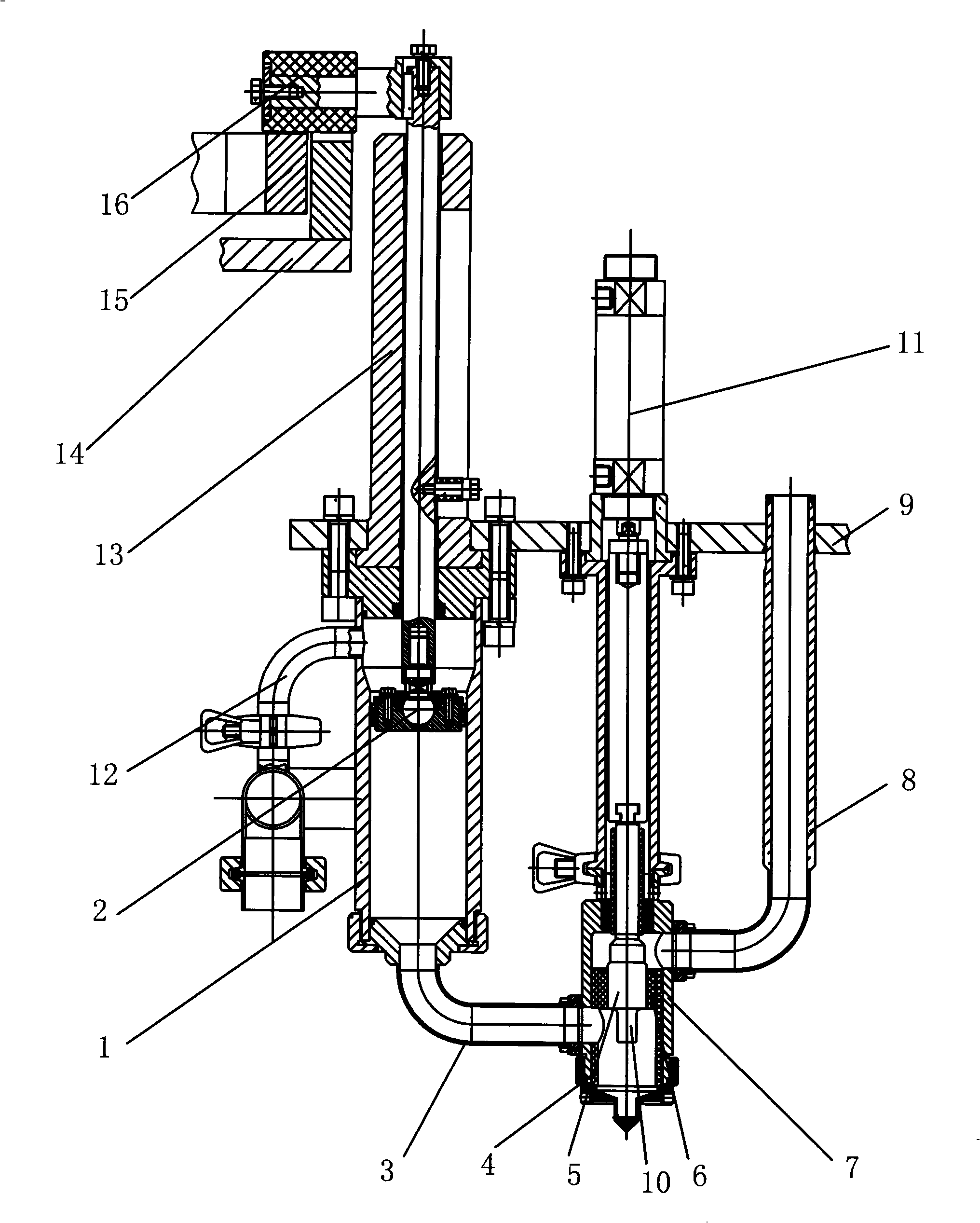

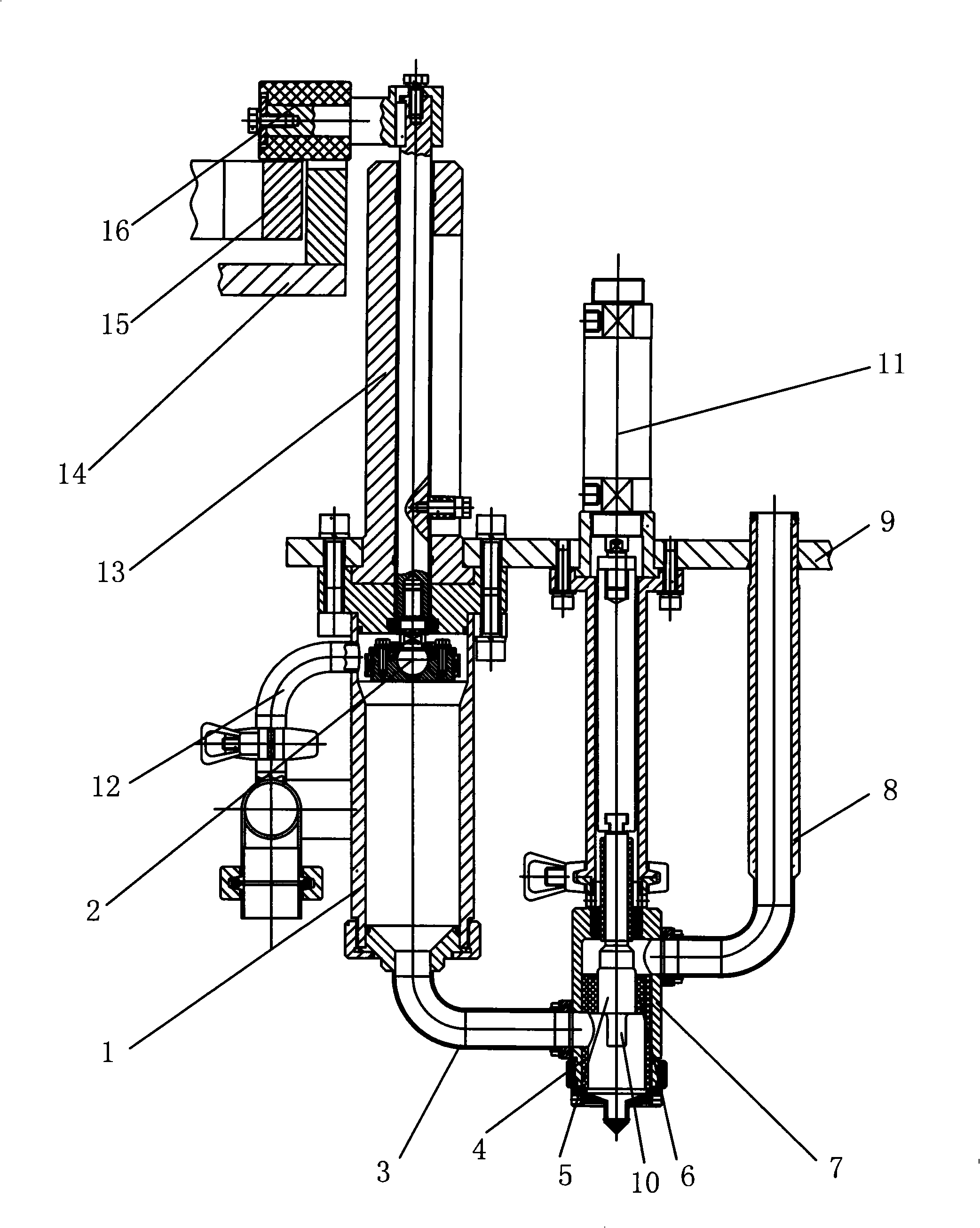

[0026] see Figure 1 to Figure 4 , The filling device of the filling machine is mainly composed of a quantitative cylinder 1, a connecting pipe, an on-off valve 7, and a valve core 5.

[0027] An inner piston 2 is arranged inside the quantitative cylinder 1 , and a first power mechanism is arranged above the inner piston 2 , and the power mechanism can make the inner piston 2 move up and down along the quantitative cylinder 1 . The bottom of the quantitative cylinder 1 is provided with a first connecting pipe 3, the quantitative cylinder 1 communicates with the first connecting pipe 3 inside, and the liquid flows from the first connecting pipe 3 to the quantitative cylinder 1 or through the first connecting pipe 3. Flow out of the quantitative cylinder 1.

[0028] The other end of the first connecting pipe 3 is connected with an on-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com