Method and apparatus for demoulding precise forming part

A precision forming and demoulding device technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of difficult to ensure the dimensional accuracy of parts, increase production costs, and increase the scrap rate, so as to reduce the scrap rate, not easy to deform, and have a long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

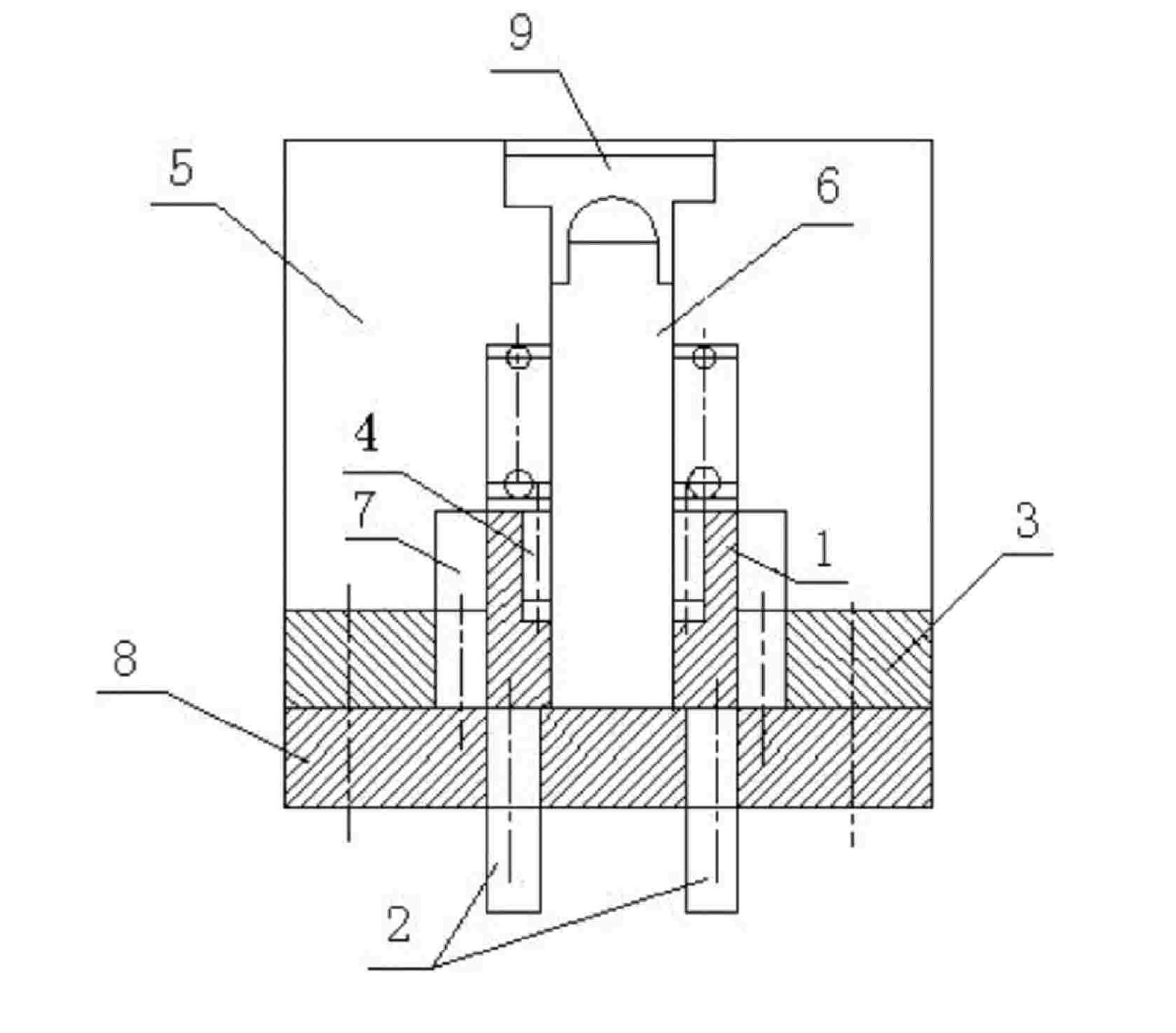

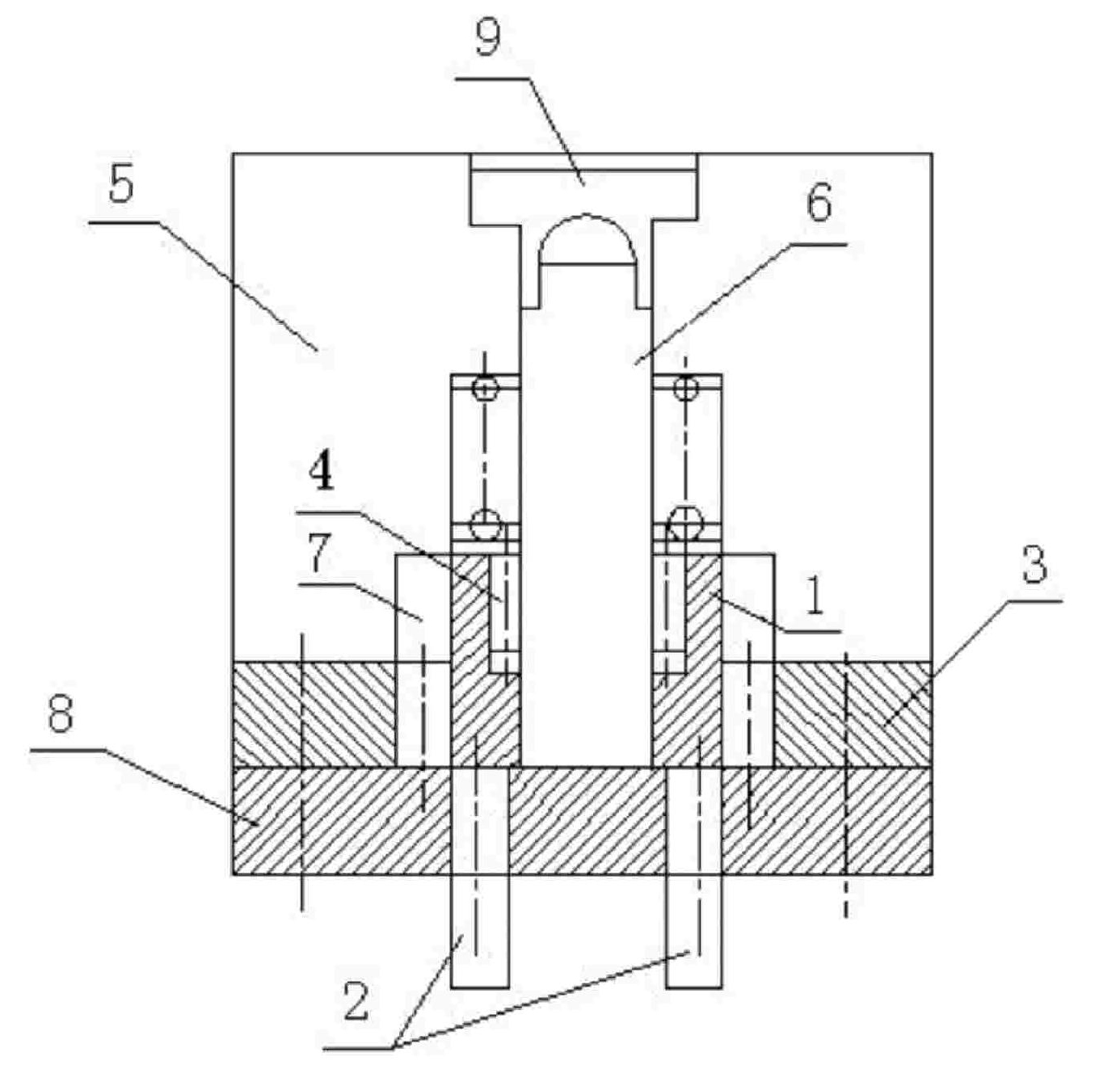

[0012] Embodiments of the present invention: as attached figure 1 As shown, it is composed of the mold core sleeve 1, the ejector pin 2 and the die sleeve 3, the mold core sleeve 1 is connected with the mold core 6 installed in the die 5 through the screw pair 4, and the screw pair 4 adopts a conventional screw The auxiliary mechanism is installed to realize the conversion of linear motion and rotary motion. In order to ensure that when the ejector pin 2 pushes the mold core sleeve 1, the mold core sleeve 1 can only move in the axial direction, the mold core sleeve 1 is also connected with the die sleeve 3 through the moving pair 7, and the moving pair 7 adopts a conventional moving pair mechanism to install. For ease of installation and operation, a backing plate 8 is also installed at the bottom of the die sleeve 3, and the top of the ejector rod 2 passes through the backing plate 8 and pushes against the bottom of the mold core rotary sleeve 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com