Guide bracket

A guiding bracket and guiding technology, applied in the field of brackets, can solve problems such as unfavorable adjustment of elastic force, lack of protection of tension springs and compression springs, fixed elastic parameters, etc., to achieve the best passability, improve service life, and protect the sealing state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

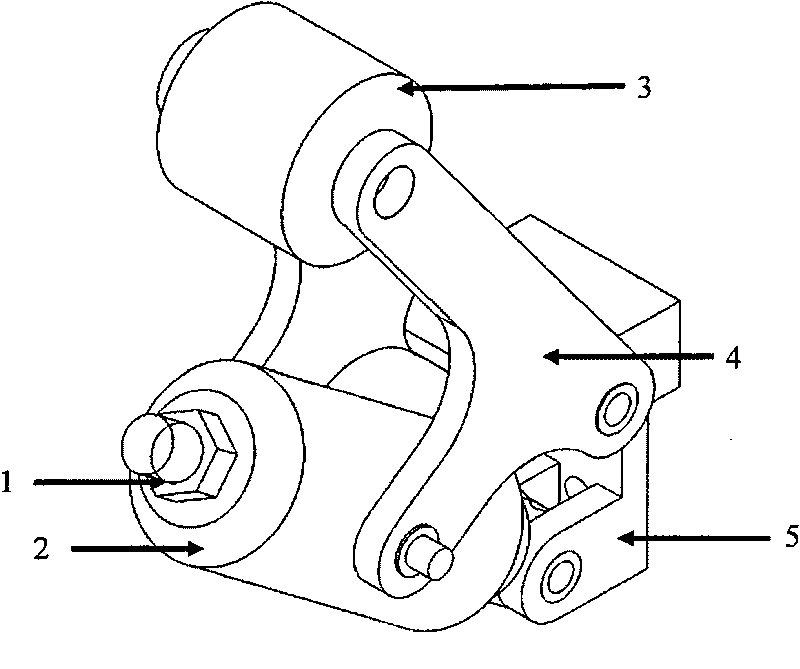

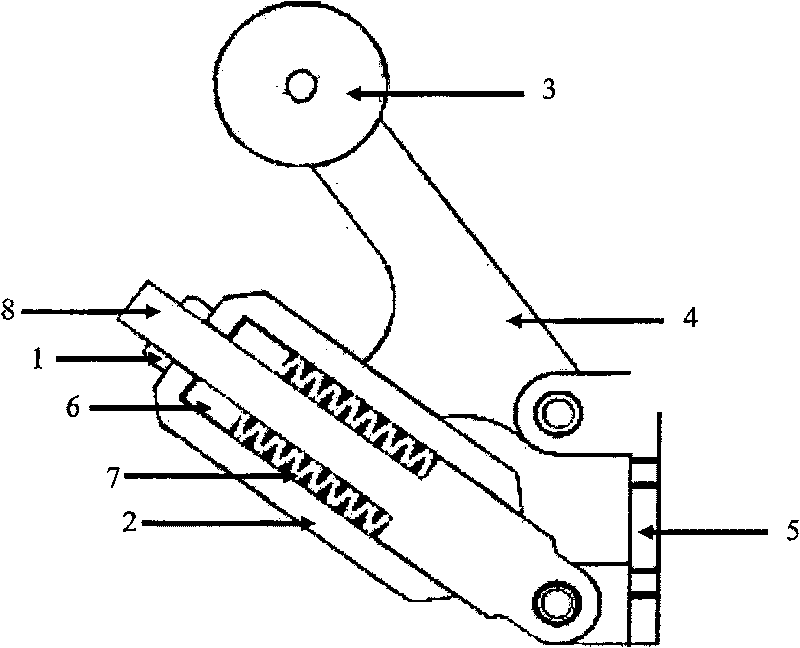

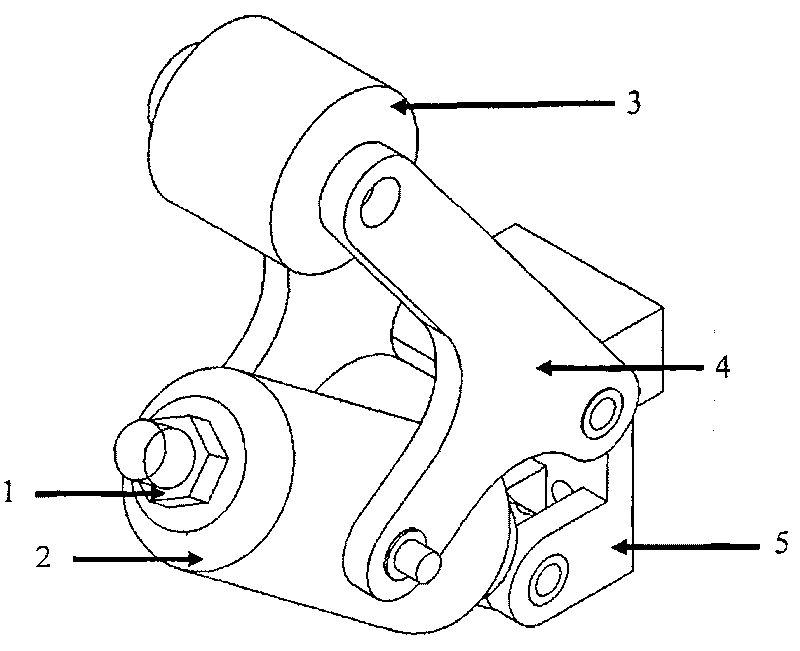

[0036] The three-dimensional structural diagram of the guide bracket with adjustable supporting force of the present invention is as follows figure 1 As shown, its internal structure diagram is shown in figure 2shown. The guide bracket is composed of a base frame 5, a three-point link 4 and an elastic component; the base frame is connected to the main body of the intelligent pig for oil pipelines; the three-point link 4 is provided with three hinge supports Seat hole, the three hinged support holes are distributed in a triangle, wherein the three-point connecting rod 4 is connected with the base frame 5 through the hinged support hole (also called the proximal hole) near the end of the base frame 5, the three points The connecting rod 4 is connected with the guide wheel 3 (also called the roller) through the hinge bearing hole (also called the distal hole) away from the base frame 5, and the three-point connecting rod 4 is connected with the third hinge bearing hole through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com