Method for down-hole multilevel micrologging for oil prospecting and electric coupler

A technology for oil exploration and micro-logging, which is applied in wellbore/well components, earthwork drilling, seismic energy generation, etc. The effect of strong interference ability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with reference to the accompanying drawings.

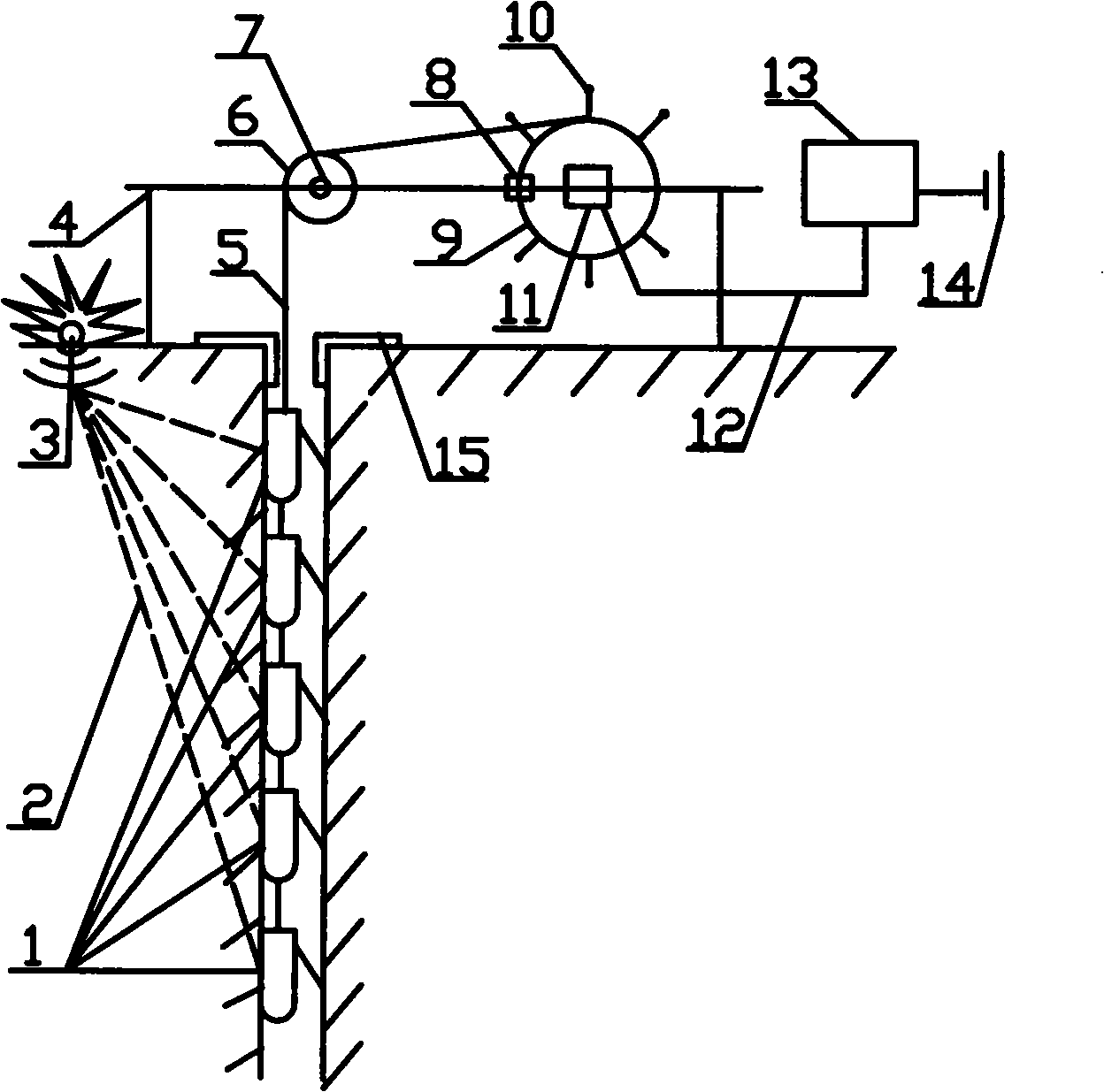

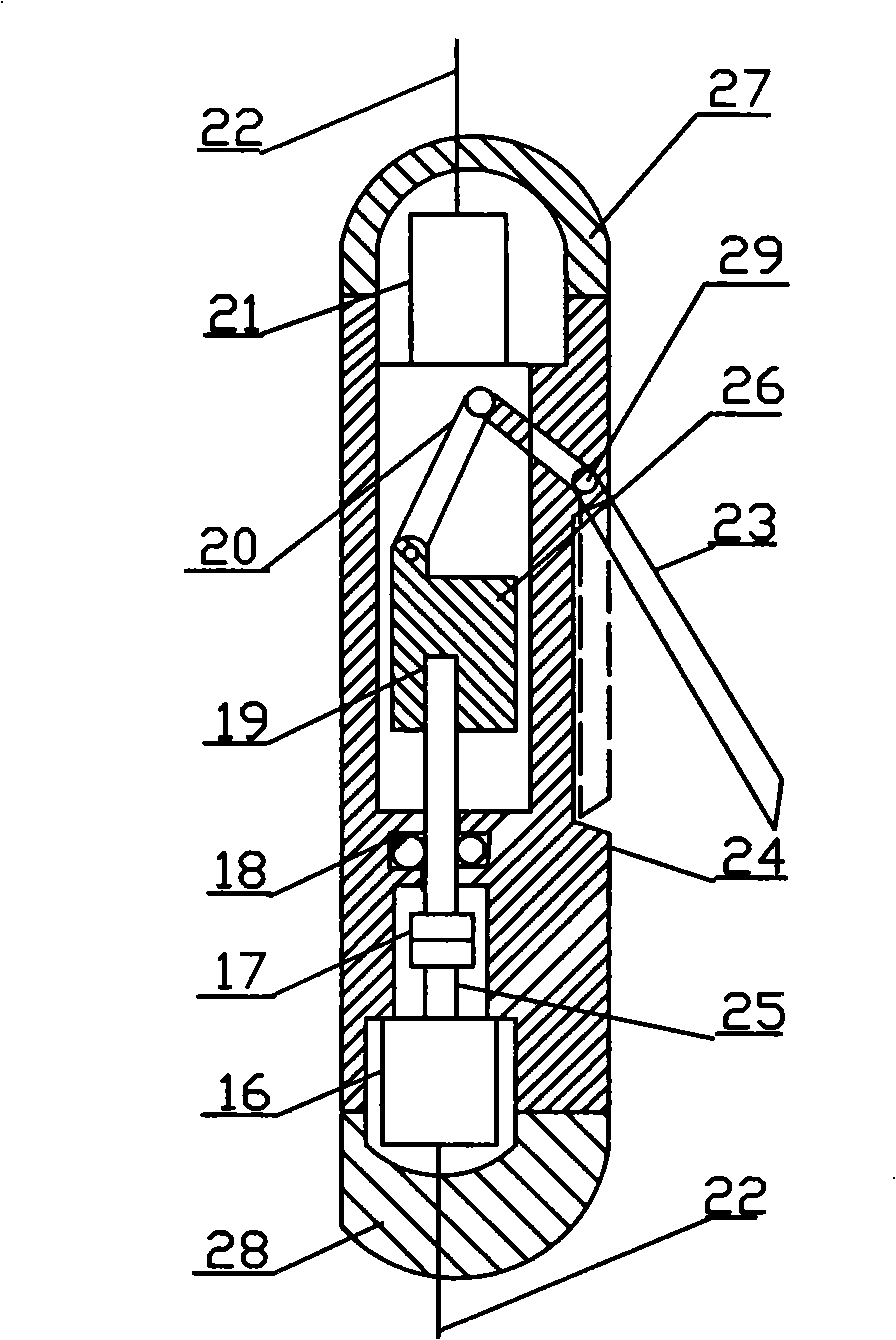

[0010] like figure 1 , figure 2 , place the wellhead protector 15 on the wellhead, turn the handle 10 to drive the drum 9 to rotate, release the cable 5 to run the electric coupler group 1 into the well through the pulley 6, and the running depth is displayed and controlled by the depth indicator 7. When the depth requirement is met, use The fixed pin 8 fixes the rotation of the drum 9, the power supply 14 is turned on, the current reaches each electric coupler 1 through the control and recorder 13, the data line 12, the collector ring 11, and the cable 5 in sequence, and the current enters the electric coupler 1 through the wire 22, The motor 16 rotates, and drives the lead screw 19 to rotate through the coupling 17 and the shaft 25, and drives the crank rocker 20 to open and close the feet 23. When the feet 23 are opened and are in close contact with the wellbore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com