Production method of level bubble shell

A production method and technology of level bubble, which is applied in the field of level bubble shell production, can solve problems such as low efficiency, inability to form a smooth transition, and reduce measurement accuracy, so as to improve measurement accuracy, facilitate smooth drift, and high concentric precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

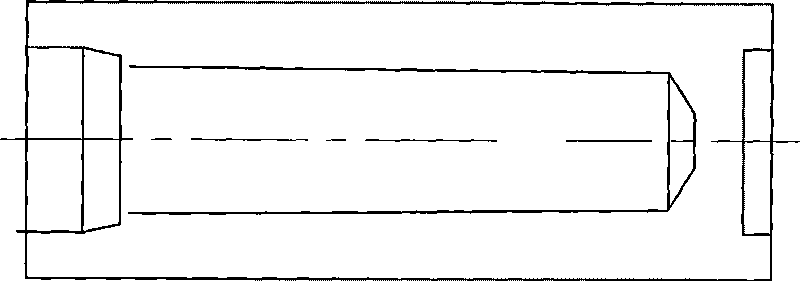

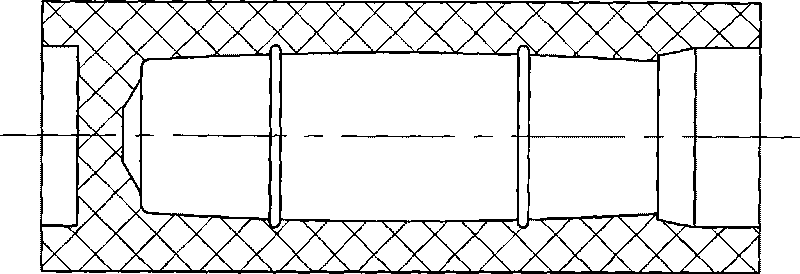

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

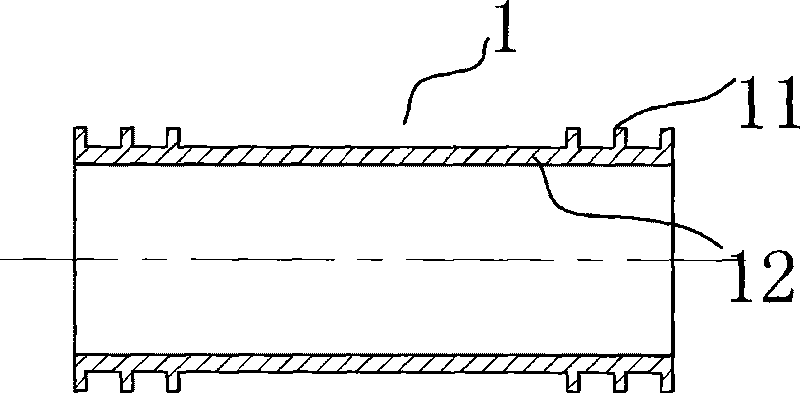

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] Such as Figure 3-5 It shows a production method of a level blister. The key point of this invention is to use a unique blister core cover 1. The blister core cover 1 is made of aluminum or copper, or plastic. When using plastic, it is best to be able to make The transparent plastic of the blister blank is of different colors, so that the engraved line is more eye-catching and prominent. The blister core sleeve 1 is produced by mold processing. During the manufacturing process, the surface of the blister core sleeve 1 is preformed with at least two or more convex rings 11. In this embodiment, there are 6 convex rings 11, and the convex rings 11 are distributed on the blister core. On the left and right sides of the surface of the cover 1, there are 3 convex rings at each end, and the blister core cover 1 is oxidized into dark black. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com