LCD device and backlight device

A technology of backlight device and liquid crystal display, applied in the field of backlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

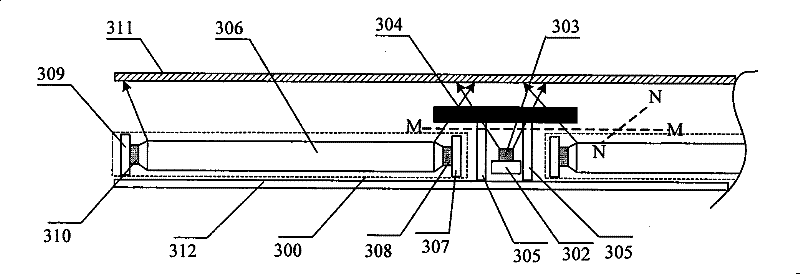

[0029] Such as image 3 Shown is a side view of an embodiment of the backlight device of the present invention, Figure 4 for image 3 A top view of the backlight device of the illustrated embodiment on the M-N plane. See also image 3 and Figure 4 , the backlight device of the embodiment of the present invention includes a casing 301, and the casing 301 may be a plastic product. Housing 301 is provided with more than one light emitting unit 300 distributed on the same plane (such as image 3 As shown in the dotted line box), a first PCB302 is arranged between two adjacent light-emitting units 300, and more than one first light-emitting source 303 is arranged on the first PCB302, and the first light-emitting source 303 is surface-attached on the first PCB302 . As a specific embodiment, the first light emitting source 303 may be a CCFL or a white LED, or a white LED including chips of three primary colors of red, green and blue. Since the red, green, and blue primary co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com