Conductive member containing fiber nanocarbon and contact device using such conductive member

A fibrous, nano-carbon technology, used in the field of contact devices and conductive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

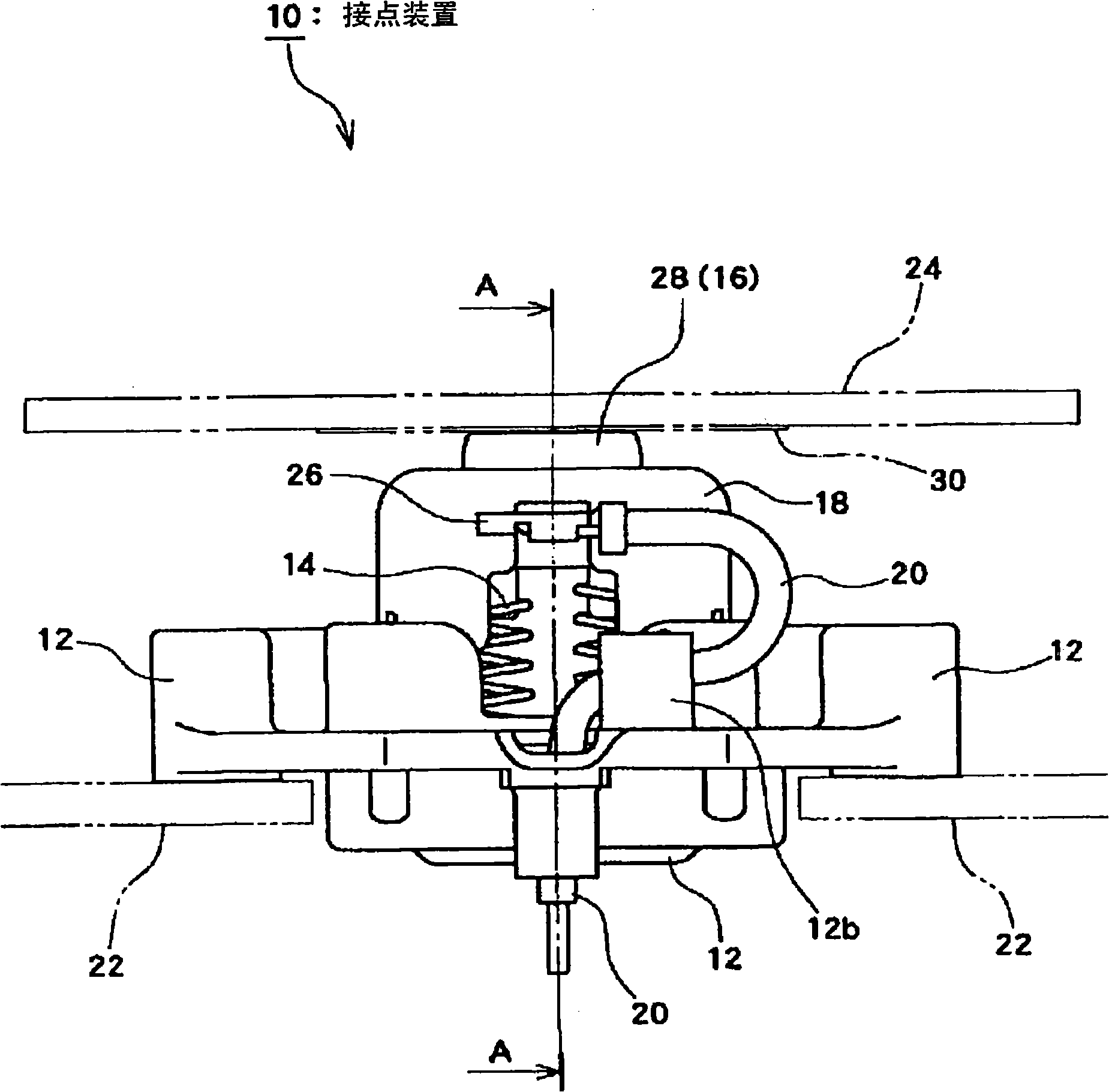

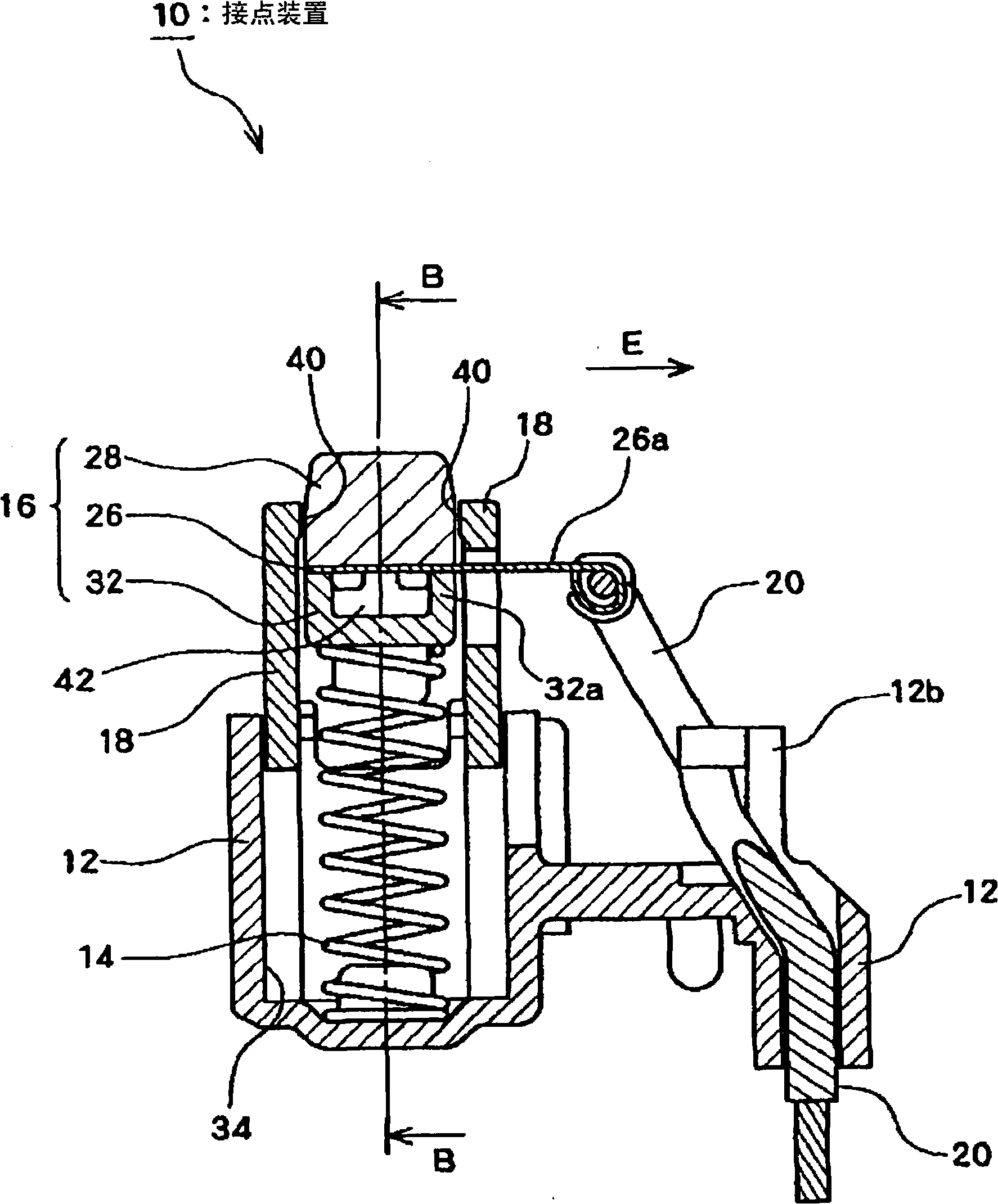

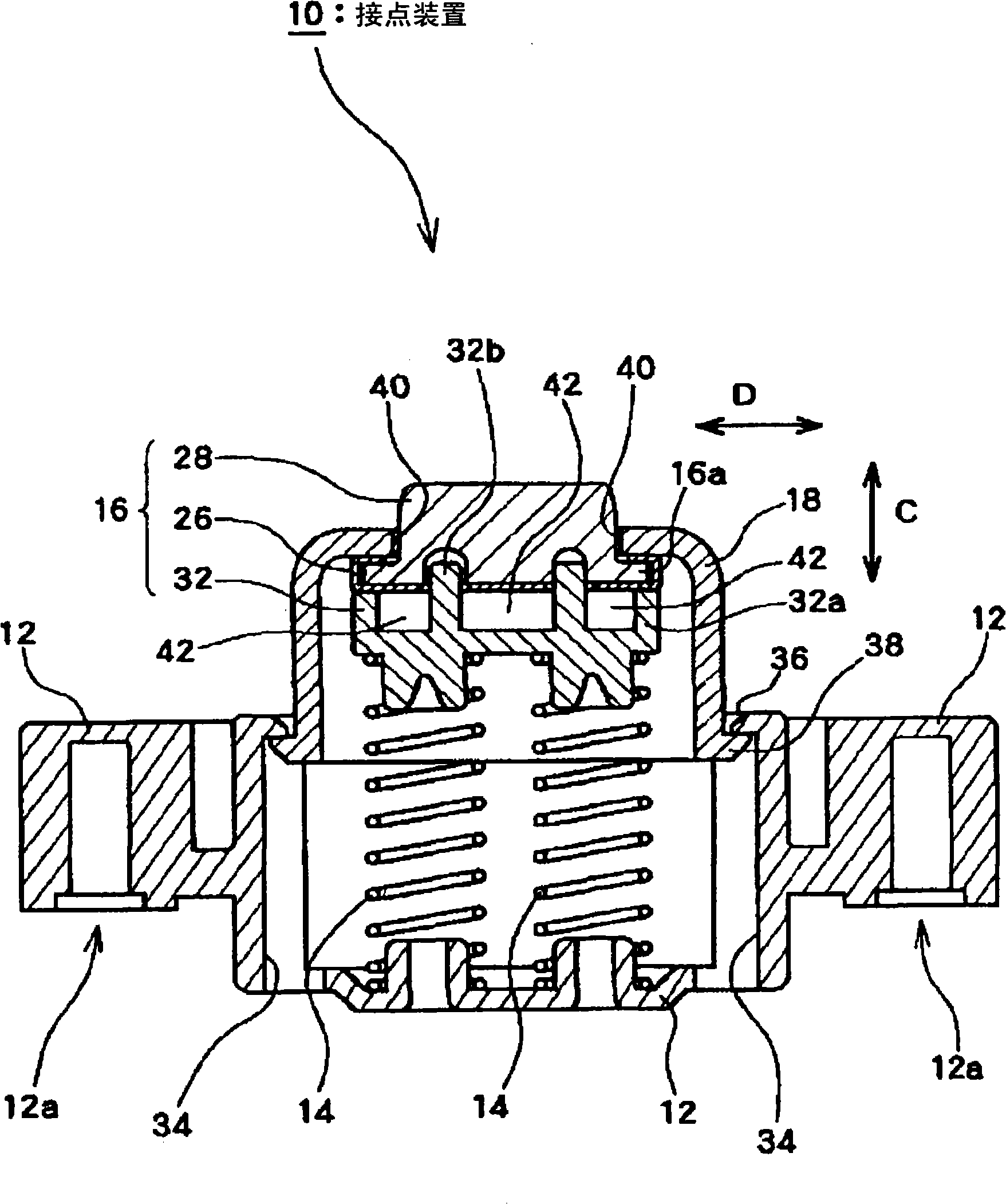

Image

Examples

Embodiment 1

[0132] 1. Make the conduction parts

[0133] (1) Preparation of multilayer carbon nanotubes

[0134] As mentioned above, the multilayered carbon nanotubes of the present invention are obtained by annealing the intermediate body produced by heating at a temperature of 800 to 1300°C at a high temperature of 2400 to 3000°C. The preferred preparation method is described in detail.

[0135] Although not particularly limited, when producing the above-mentioned carbon fiber structure, it is preferable to use at least two or more carbon compounds having different decomposition temperatures as carbon sources. The so-called at least two or more carbon compounds here do not necessarily use two or more substances as raw organic compounds. Reaction such as hydrodealkylation (hydrodealkylation) of toluene or xylene, which turns into two or more kinds of carbon compounds with different decomposition temperatures in the subsequent thermal decomposition reaction system is also included. Fur...

Embodiment 2

[0148] Multilayered carbon nanotubes were produced in the same manner as in Example 1, and conducting members were produced in the same manner as in Example 1 except that 15 parts by weight of the obtained multilayered carbon nanotubes were used. The transfer characteristics of the obtained conduction member were evaluated in the same manner as in Example 1. The results are shown in Table 1. In the transfer characteristics, a further improvement in performance was observed.

Embodiment 3

[0150] In addition to using 10 parts by weight of carbon nanofiber [VGCF (registered trademark), Showa Denko Co., Ltd.] synthesized by the gas phase method instead of the multilayer carbon nanotube used in Example 1, the others are the same as in Example 1. Conductive parts were fabricated. The transfer characteristics of the obtained conduction member were evaluated in the same manner as in Example 1. The results are shown in Table 1. Compared with the conduction member of Example 1, the transfer characteristic was slightly inferior, but it was still at a level that could be used as a conduction member.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com