Intelligent experimental bench for driver performance test

A technology for testing experiments and drives, which is applied to the testing of machines/structural components, instruments, measuring devices, etc., and can solve problems such as failure to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below.

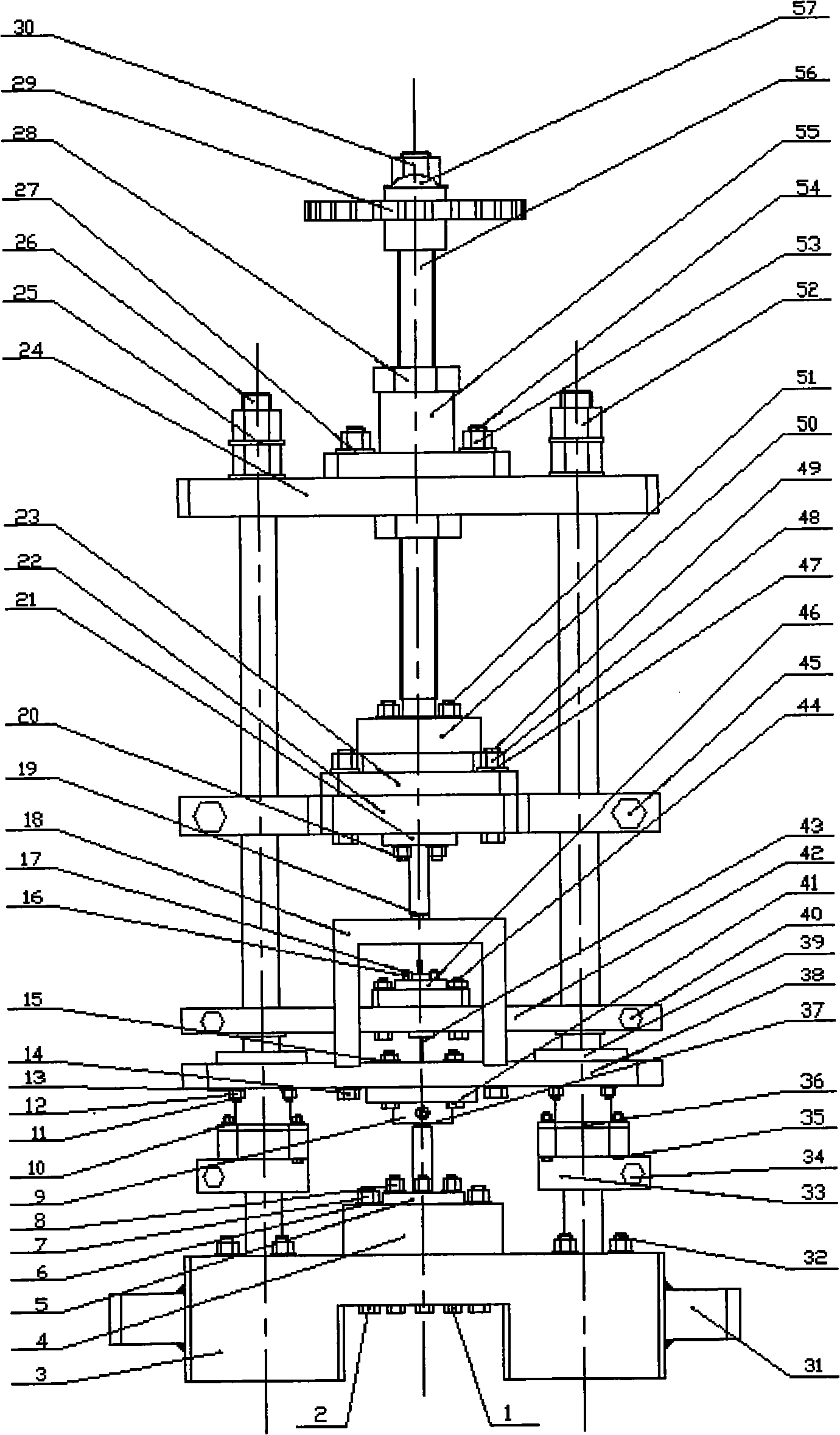

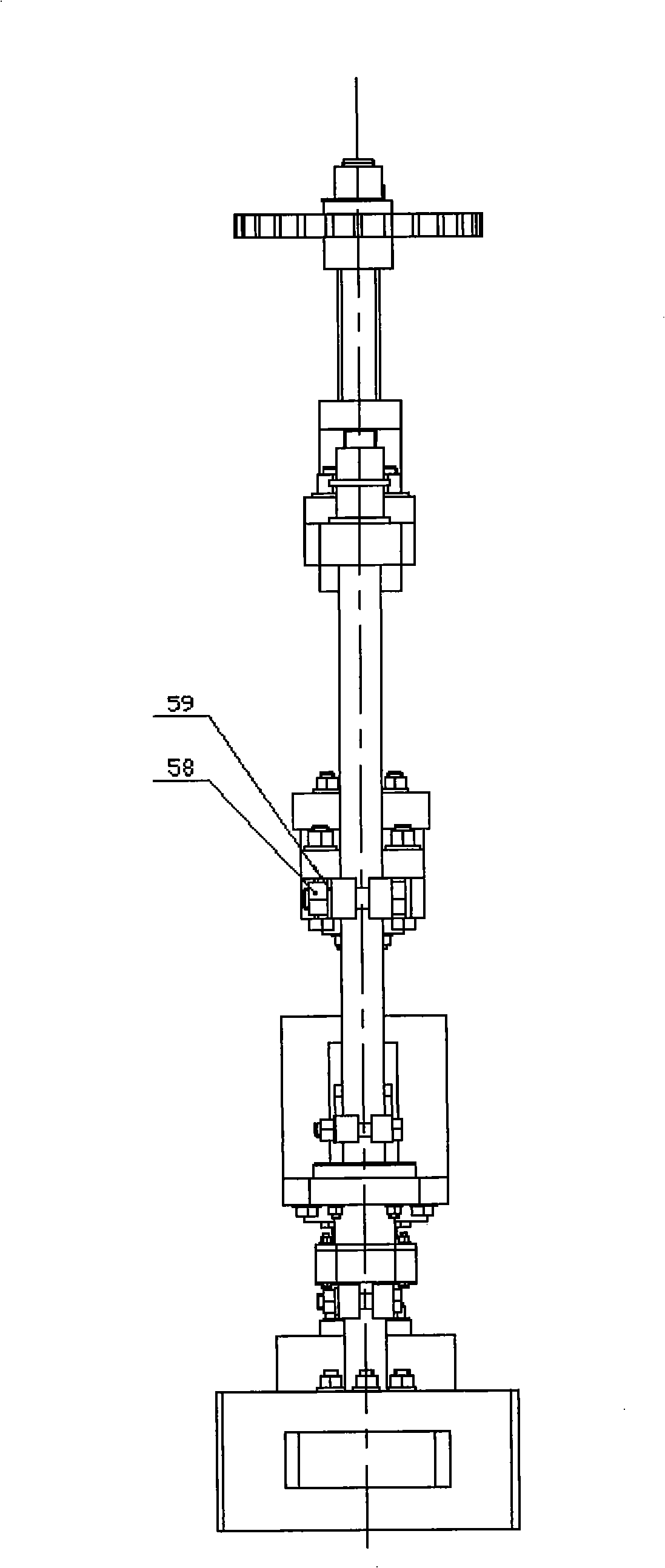

[0017] The intelligent driver performance test bench is mainly composed of three major systems: skeleton system, force application system, and micro displacement test system. Among them, the skeleton system is the basic support part of the test bench, which is used to support the force application system, the micro displacement test system and the tested intelligent driver; the force application system can apply various forces to the tested intelligent driver to test the tested intelligent driver The load characteristics; the micro-displacement test system is used to test the output displacement of the tested intelligent driver (in free state or load state).

[0018] Wherein the framework system mainly comprises: base 3, made of stainless steel, is used to support the whole test bench system; guide rail 26 (there are two identical), made of stainless steel, its processing accuracy requirement is very hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com