Folding type milling foot pressing apparatus of double surfacer

A presser foot device and presser foot technology, applied in the direction of manufacturing flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problem of uneven pressing and restraint, affecting wood surface quality and processing accuracy, and uneven presser feet Ground compression constraints and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

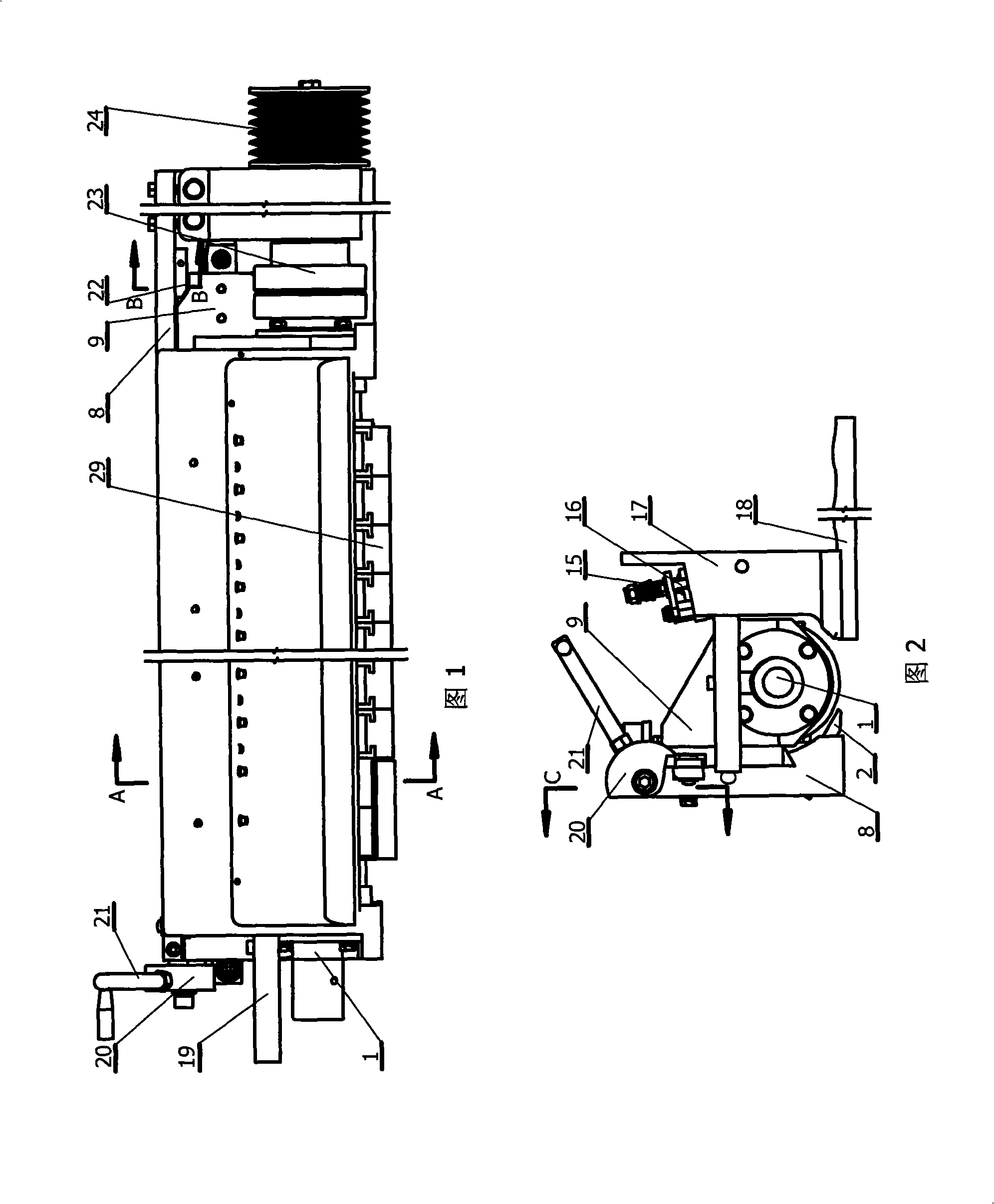

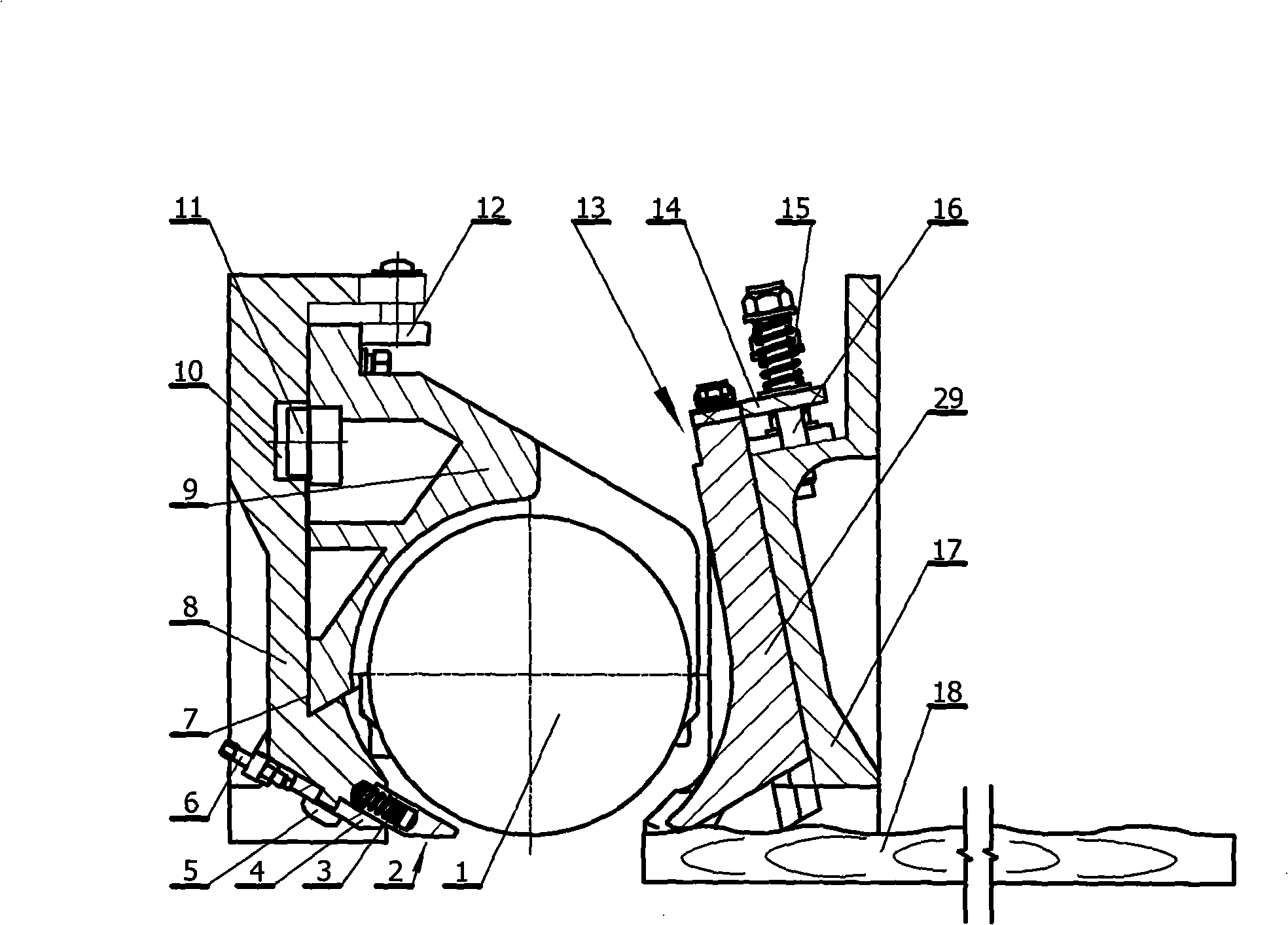

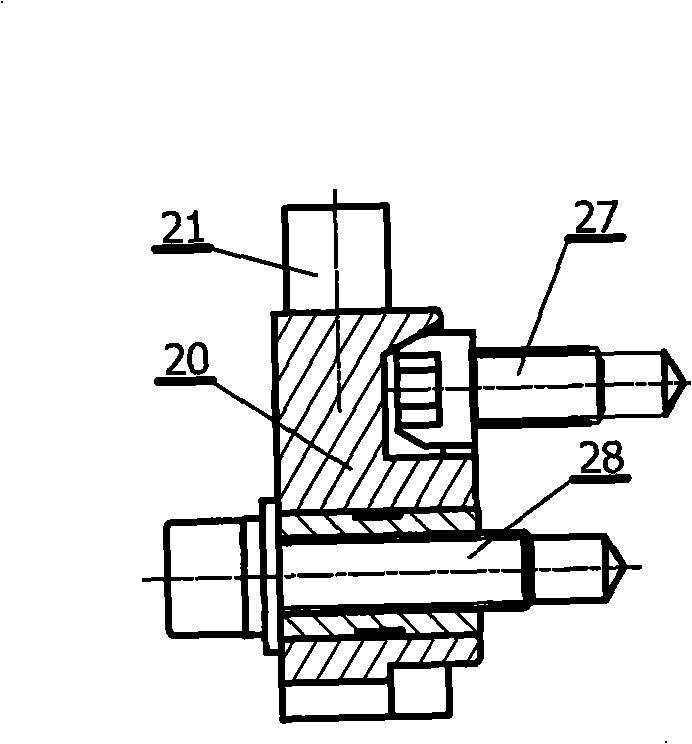

[0030] In the double-sided planing and stacking planing presser foot device shown in Figure 1 and Figure 2, the fixed knife seat 8 and the front presser foot support 17 are all fixedly installed on the frame of the double-sided wood planer (the not shown), the upper cutter shaft 1 is equipped with a detachable and adjustable planer blade, and the journal parts at both ends of the upper cutter shaft 1 are respectively supported on the cutter shaft seat 9 through bearings, and the cutter shaft seat 9 is slidably supported on a fixed On the knife seat 8. The driving pulley 24 is rotatably supported on the fixed knife seat 8, the driving pulley shaft and the upper knife shaft 1 are kept on the same center line, and the upper knife shaft 1 and the driving pulley shaft are connected to each other through a coupling 23, and the coupling 23 adopts a detachable universal claw type elastic coupling. Its two detachable claw-type half-couplings are fixedly connected to the pulley shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com