Supply of magazines via the conveyor of a circuit board transport system with multiple conveyor paths

A technology of transmission lines and transmission lines, applied in the direction of electrical components, electrical components, etc., can solve the problems of lower assembly process efficiency, prolong the moving distance of assembly heads, etc., and achieve the effect of short time interval and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

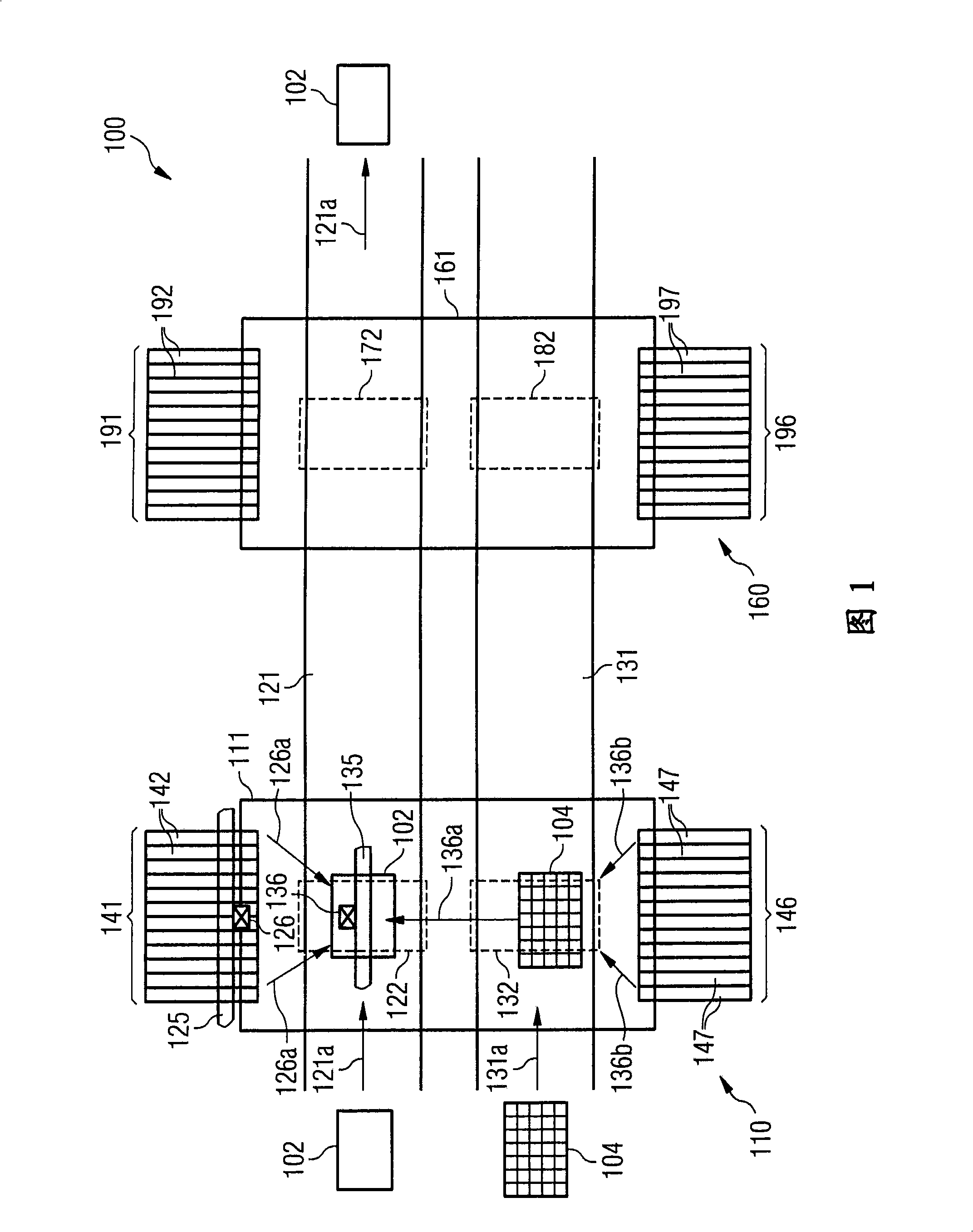

[0056] FIG. 1 shows an assembly system 100 with two automatic assembly devices, a first automatic assembly device 110 and a second automatic assembly device 160 . The two automatic assembly machines 110 and 160 are connected on a bidirectional transport system for circuit boards or component carriers. The bidirectional transmission system has a first transmission line 121 and a second transmission line 131 , which run parallel to one another. Two transport lines 121 and 131 are provided in a known manner for transporting component carriers 102 to be assembled.

[0057] As can be seen, for example, in FIG. 1 , according to the exemplary embodiment of the invention shown here, a first transport line 121 for transporting component carriers 102 to be assembled along a transport direction 121 a into a first assembly area 122 . Not shown otherwise for reasons of clarity, the first transport line 121 is also used for the at least partially assembled component carriers 102 to escape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com