Printing and embossing machine and printing and embossing method thereof

A technology of embossing and printing, applied in textile and papermaking, fabric surface trimming, winding strips, etc., can solve the problem of large difference in pattern, high displacement rate of pattern plate, and difficulty in maintaining the center of pattern plate for grey fabric. The problem of always overlapping, etc., achieves the effect of convenient operation, improved processing quality and output, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

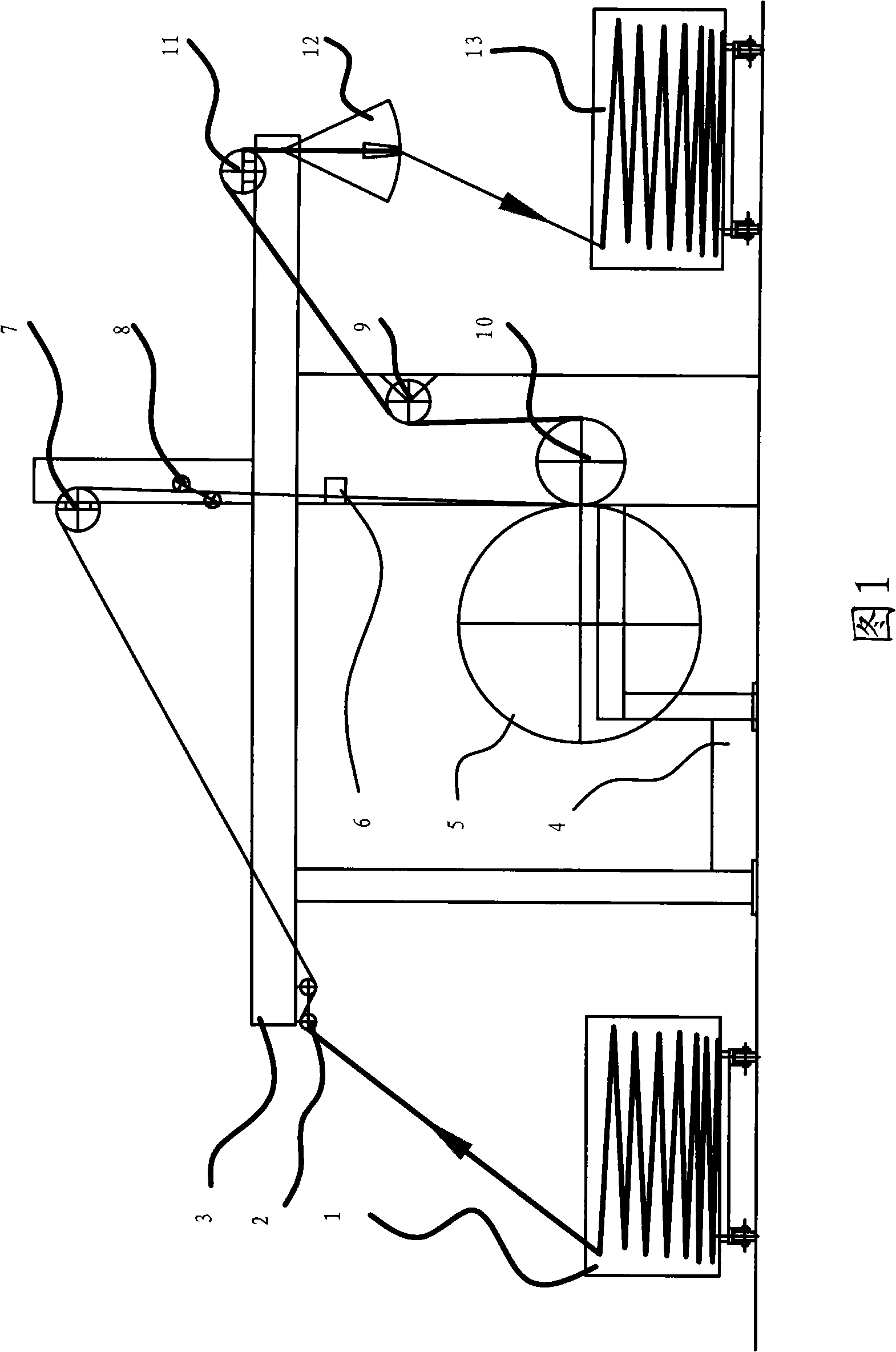

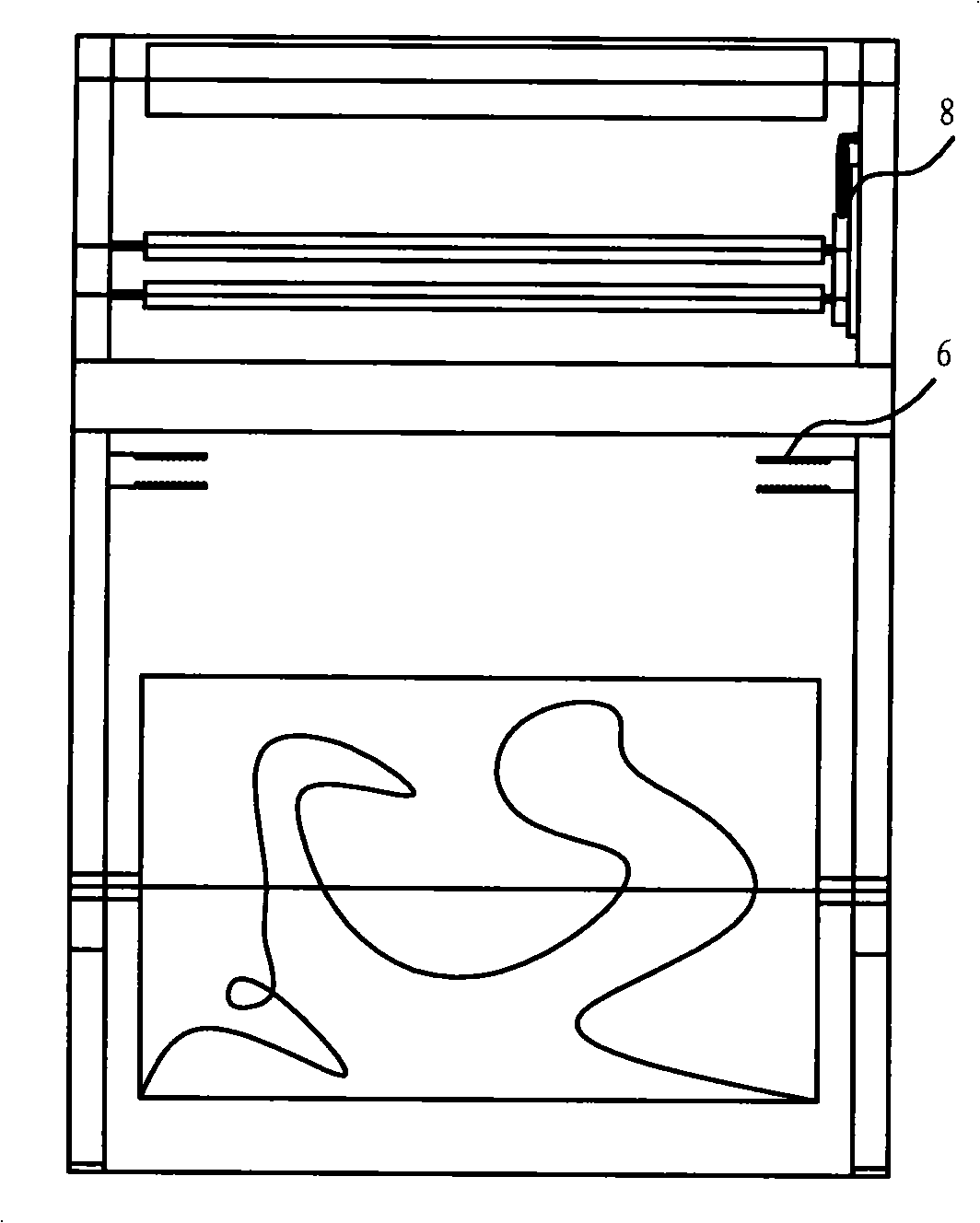

[0033] Figure 1, figure 2 As shown, the printing and embossing machine is mainly composed of a cloth feeding car 1, a frame 3, and a cloth receiving car 13. The embossing die roller 5 and the cloth pressing roller 10 are installed under the frame 3, and the embossing die roller 5 is controlled by the operating pedal 4. Control, the centering device infrared detector 6 is installed above the embossing die roller 5, the centering device actuator 8 is installed above the centering device infrared detector 6, and the centering device is a slidable roller consisting of two rollers , the staggered displacement of the two rollers can cause the center position of the fabric to shift, and the cloth guide roller 7 is installed directly above the actuator 8 of the centering device, and the tension adjustment system 2 is installed between the cloth feeding vehicle 1 and the cloth guide roller 7, The tension adjustment system 2 is composed of more than two cloth guide rollers arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com