Temporary soil sheathing apparatus

A technology of supporting device and soil layer, applied in construction, excavation, infrastructure engineering, etc., can solve the problems of reducing working space, increasing construction cost, reducing work efficiency, etc., to increase working space, reduce material use, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

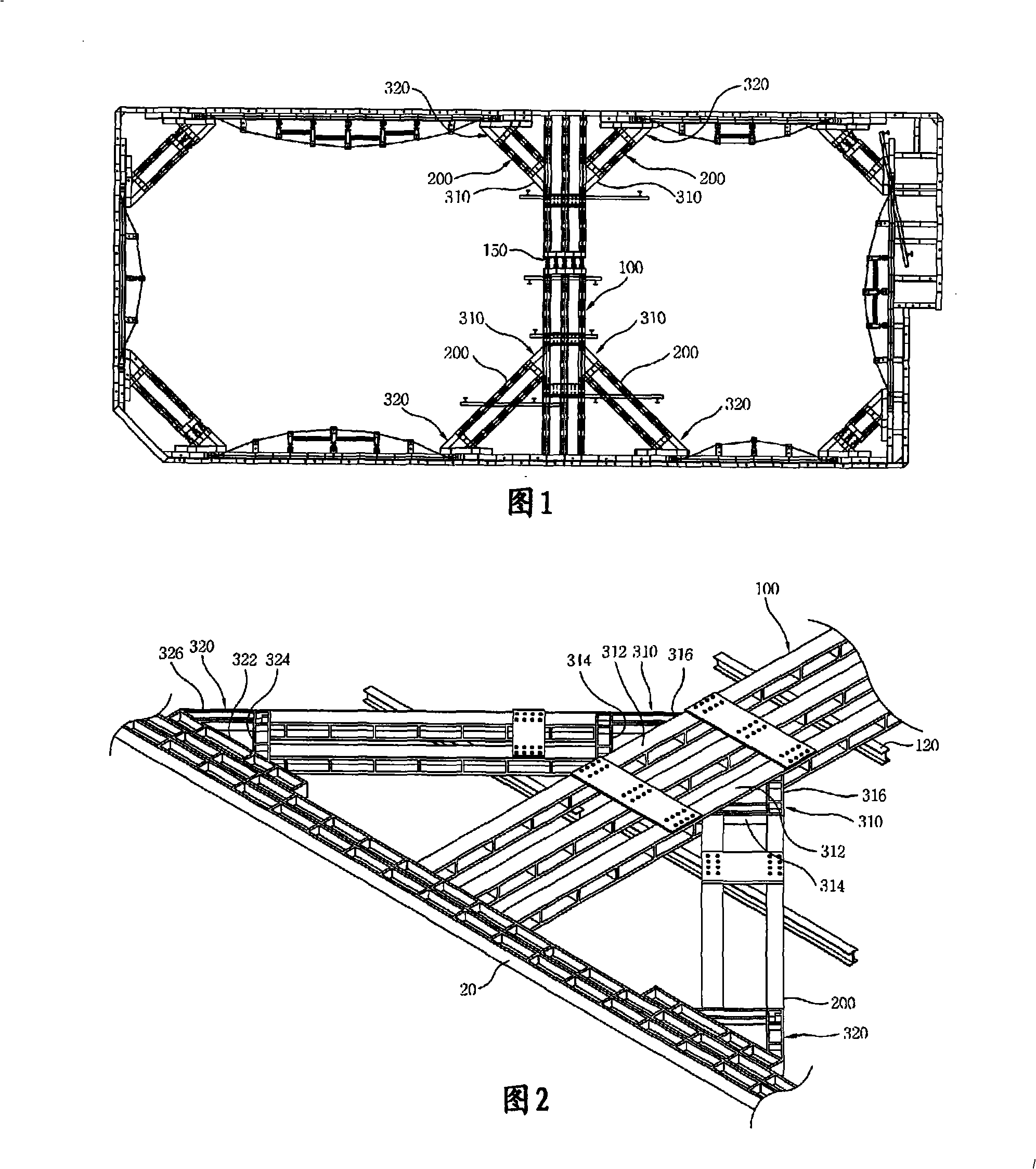

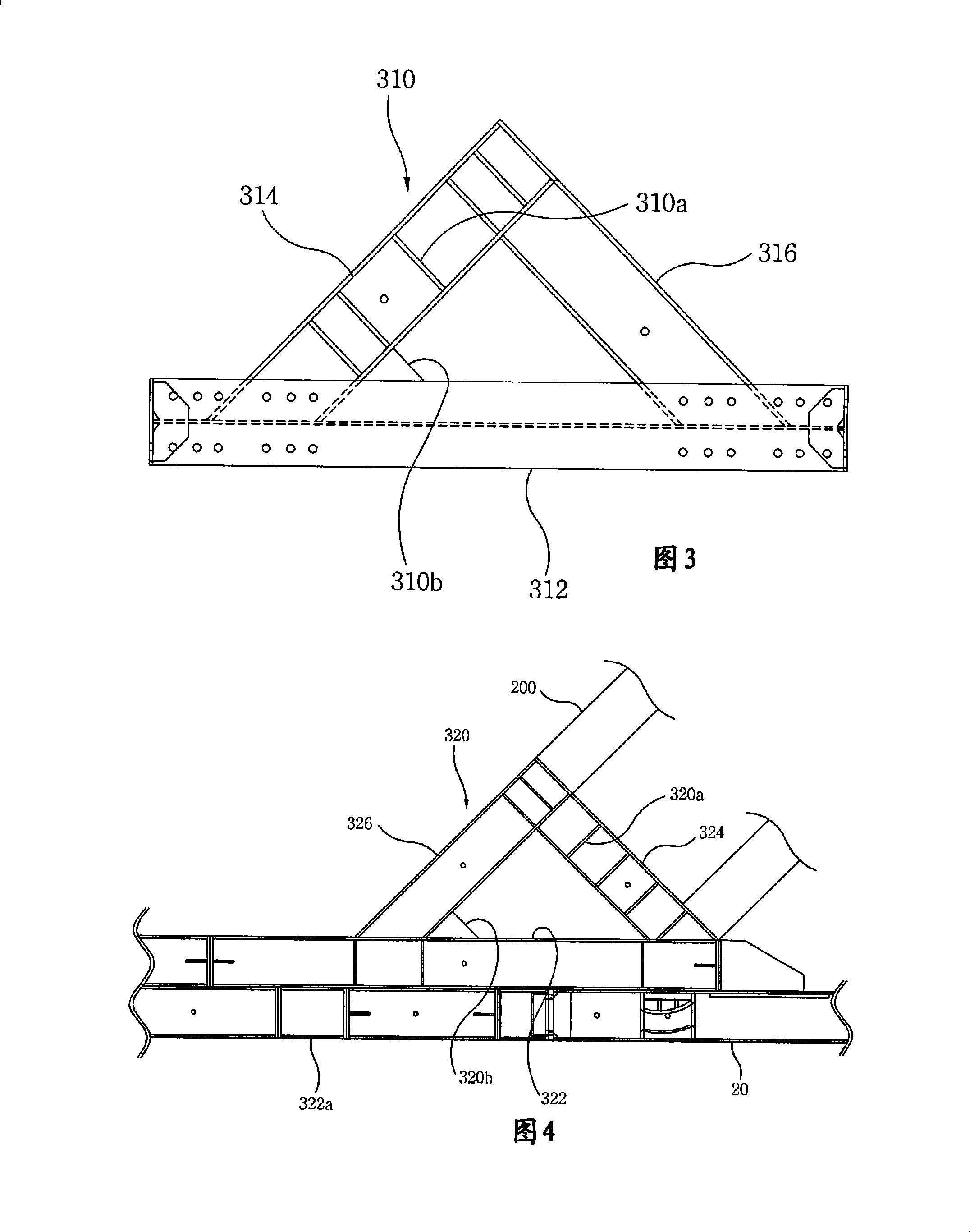

Image

Examples

Embodiment 3

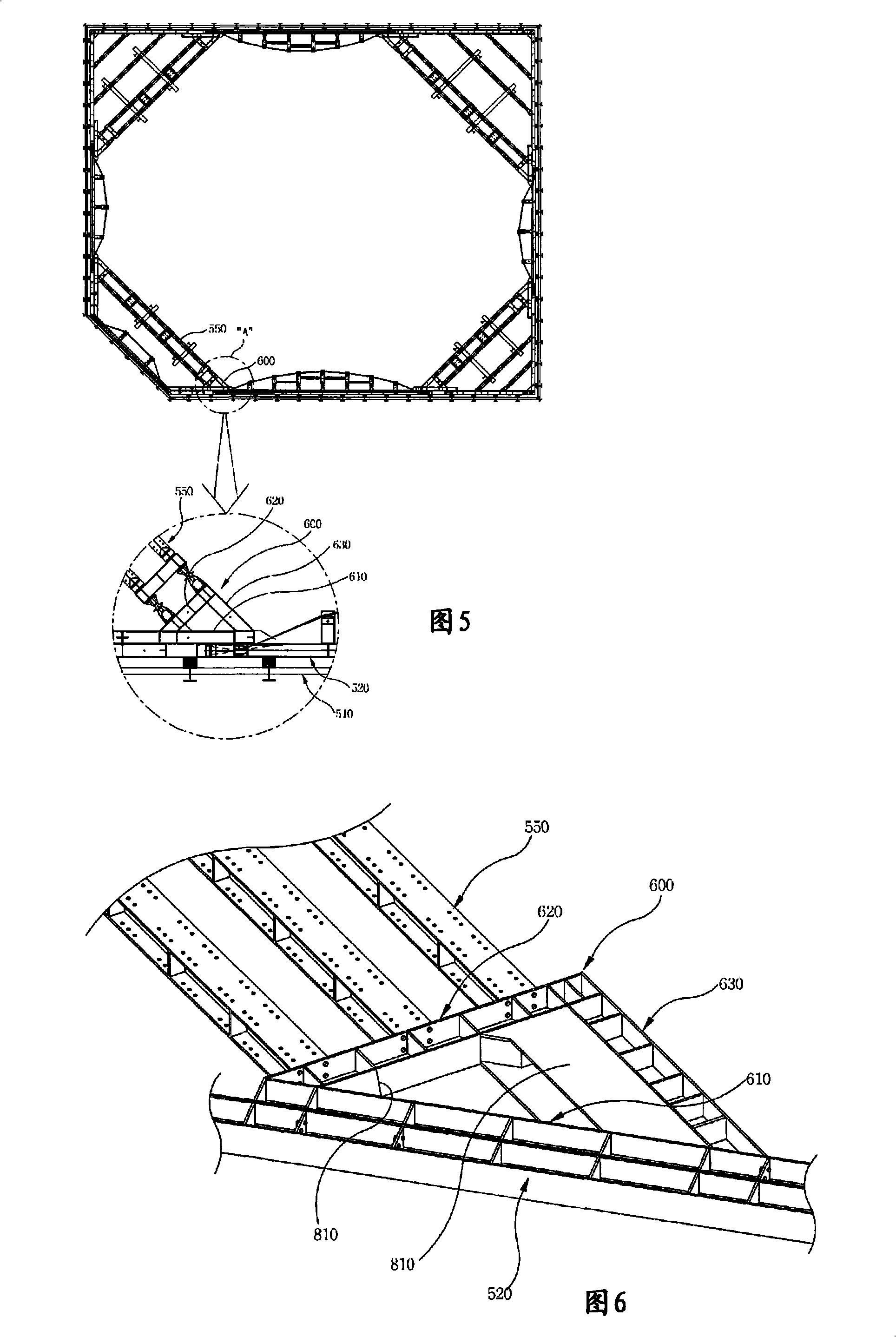

[0082][79] The temporary soil layer support device according to the third embodiment of the present invention further includes a corner connection structure, which is arranged in a row at each corner when performing excavation work for constructing an underground structure, and in a truss structure Integral, suitable for uniform transmission of horizontal loads, so that sufficient capacity to withstand bending loads is obtained using coupling beams.

[0083] [80] Referring to FIGS. 9 to 13, the temporary soil layer support device according to the third embodiment of the present invention includes: coupling beams 1100, which are obliquely arranged in rows at each corners, and both ends are supported on the supporting wall 1010; and at least one connection plate 1200 interconnecting the upper or lower surfaces of adjacent coupling beams 1100 using coupling members.

[0084] [81] More specifically, the connection plate 1200 has a rectangular shape, and has at least one rigid memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com