Device for rapidly checking capsules weight

A capsule and weight technology, which is applied in the field of devices for quickly detecting the weight of capsules, and can solve problems such as material blockage and low weighing efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

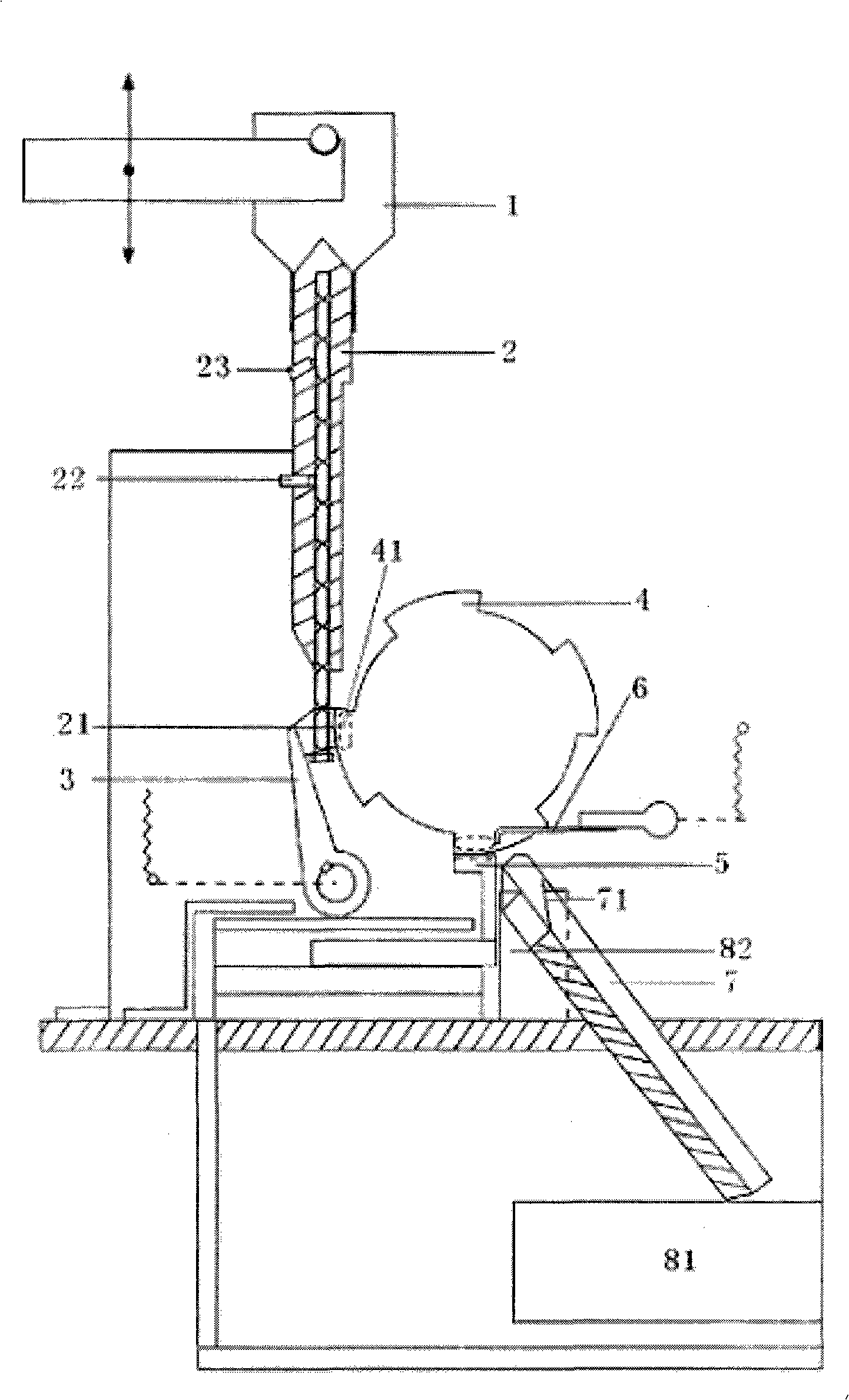

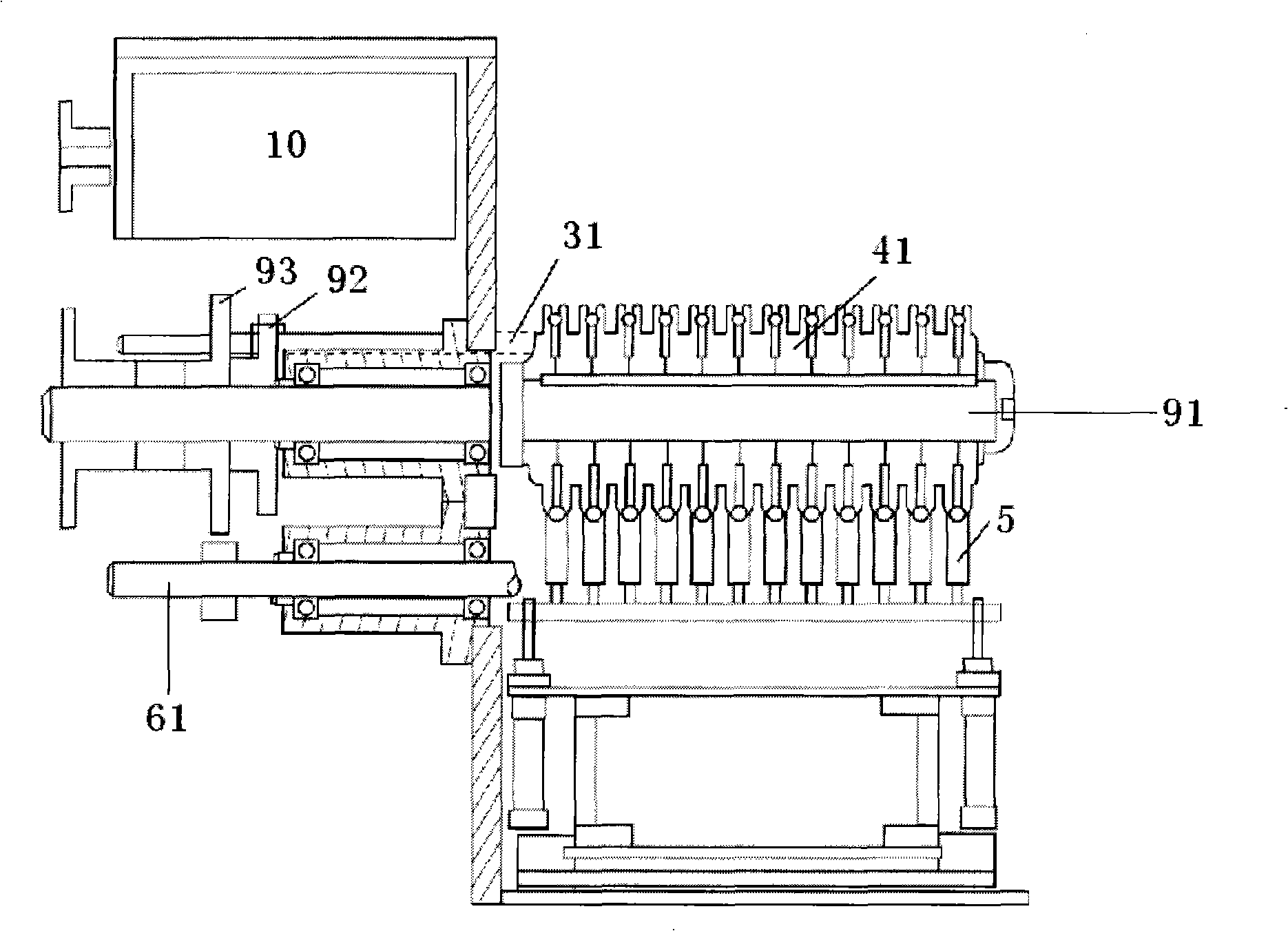

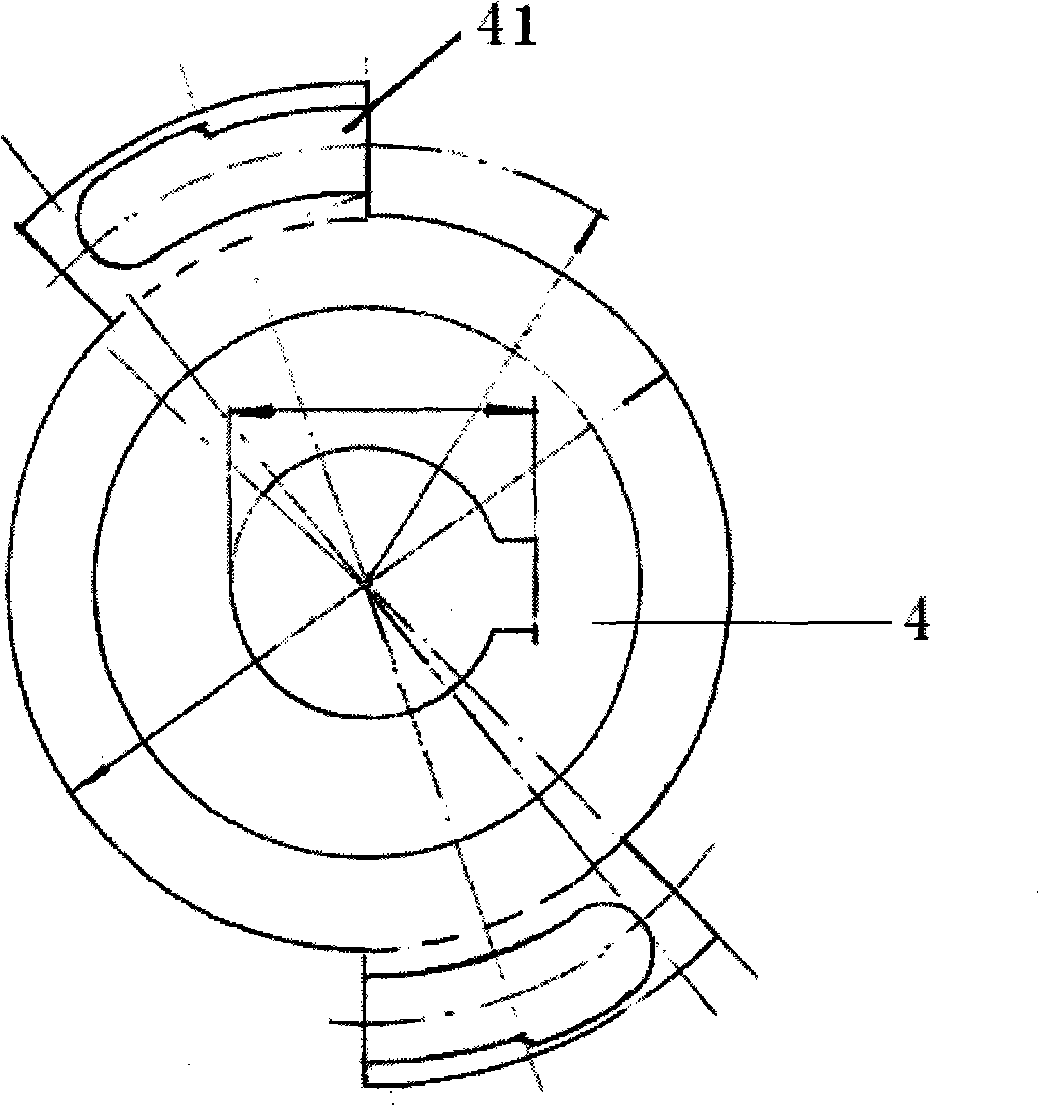

[0017] see figure 1 , 3 , which is the structural principle diagram of a device for rapidly detecting the weight of capsules of the present invention. As shown in the figure: it consists of a silo 1, an upper channel 2, a feeding lever 3, a feeding impeller 4, a weighing platform 5, a stopper needle 6, and a lower channel 7; among which: the bottom of the silo 1 is open. Corresponding to the opening of the upper end of the upper channel 2 arranged vertically, the upper channel 2 can be used for the capsules to slide down in turn; the lower end of the upper channel 2 has a discharge port 21, and one side of the discharge port 21 has a material that can extend into and out of the discharge port 21. The above-mentioned feeding lever 3 of the outlet 21, the other side of the outlet 21 is provided with a feeding impeller 4 with a storage tank 41 around it; when the storage tank 41 of the feeding impeller 4 rotates to the position corresponding to the outlet 21, the feeding dial T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com