Dual spindle gas spring and working method

A working method and gas spring technology, applied in the field of gas spring manufacturing, can solve problems such as one-way elongation or compression, and achieve the effect of novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

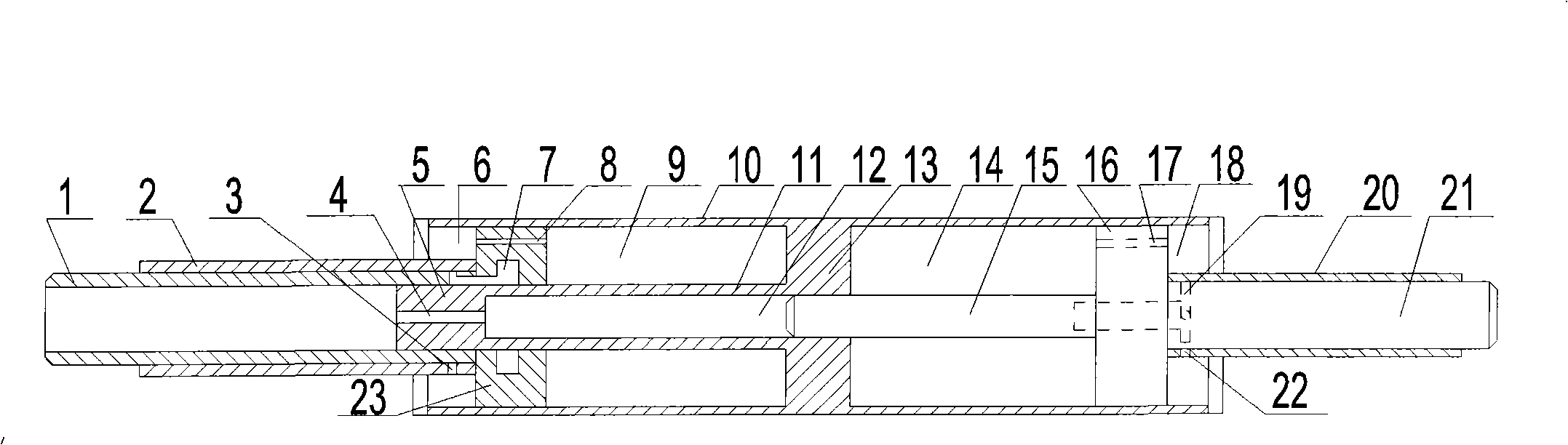

[0009] Example 1: refer to the attached figure 1 . The cylinder block of the double-shaft gas spring is a left and right cavity, the pistons in the left and right cavities are respectively provided with through holes, and one end of the left and right shafts respectively passes through the shaft holes in the left and right end covers of the cylinder block, respectively, and one end face of the left and right pistons The shaft connecting the left and right shafts is provided with grooves, the left and right shaft rotating sleeves are respectively sleeved on the left and right shafts, and the left and right shaft rotating sleeves are respectively provided with small holes, and the shafts are solid shafts or hollow shafts. That is to say, the middle of the cylinder block 10 of the double-shaft gas spring is provided with a plunger partition 13 and divides the cylinder block 10 into left and right cavities. The middle of the plunger partition 12 and the cylinder are provided with ...

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the working method of the double-shaft gas spring, the middle of the cylinder block 10 is provided with a plunger partition 13 and the cylinder block 10 is divided into left and right cavities, the middle of the plunger partition 12 and the column The body is provided with a guide hole 12, the guide rod 15 is located in the guide hole 12 and stretches along the guide hole, the right cavity piston 16 is sleeved on the guide rod 15 and is located in the right cavity 14 of the gas cylinder, and the right cavity piston has a through small hole. Hole 17, one end of the shaft 21 passes through the shaft hole in the end plate of the gas cylinder and is connected to the end face of the right cavity piston 16, and the shaft 21 is provided with a groove 19, and the shaft rotating sleeve 20 is sleeved on the shaft 21 and has a small hole on it. Hole 22, the left cavity piston 23 is sleeved on the plunger part of the plunger partition 13 a...

Embodiment 3

[0011] Example 3: On the basis of Example 2, when the left and right pistons need to be extended at the same time, the small hole on the shaft rotating sleeve and the small hole on the hollow shaft rotating sleeve are sealed with the shaft and the hollow shaft. The area of the left and right chambers in the left chamber piston chamber is equal, and the area of the left and right chambers in the right chamber piston chamber is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com