Vibrating plate with individually adjustable vibration generators

A vibration exciter, a single exciter technology, applied in the direction of the use of vibration fluid, soil protection, roads, etc., can solve the problems of high cost and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

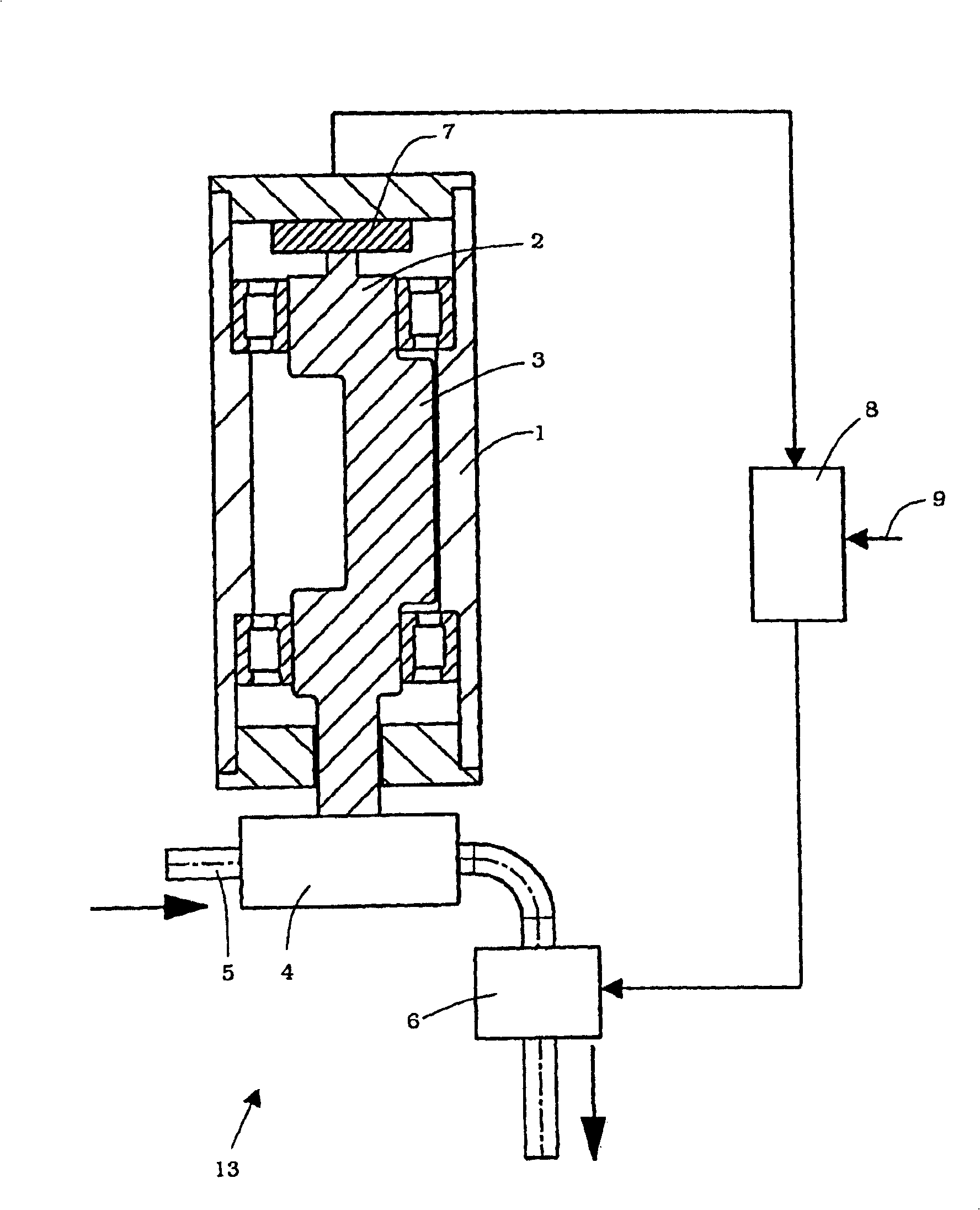

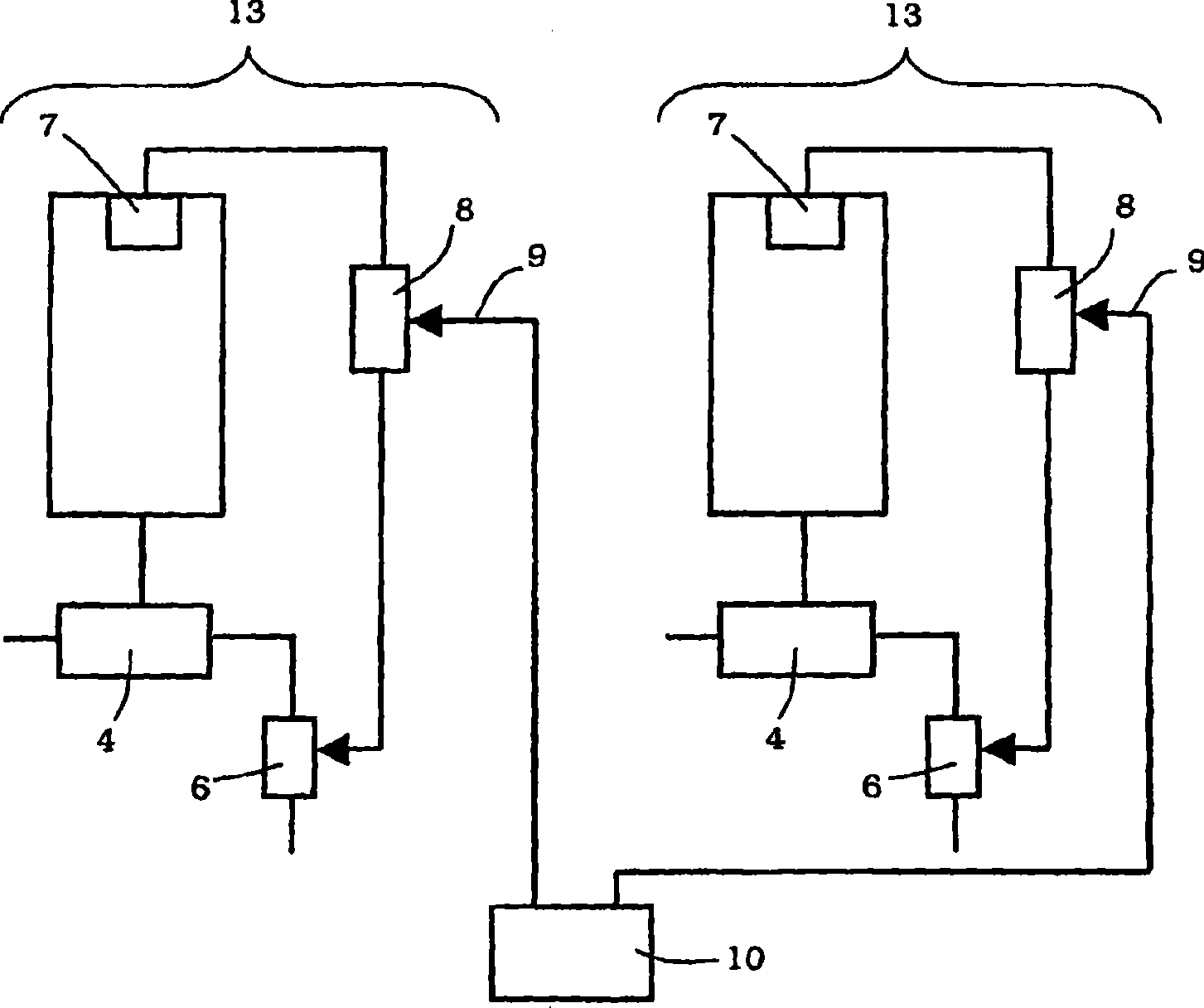

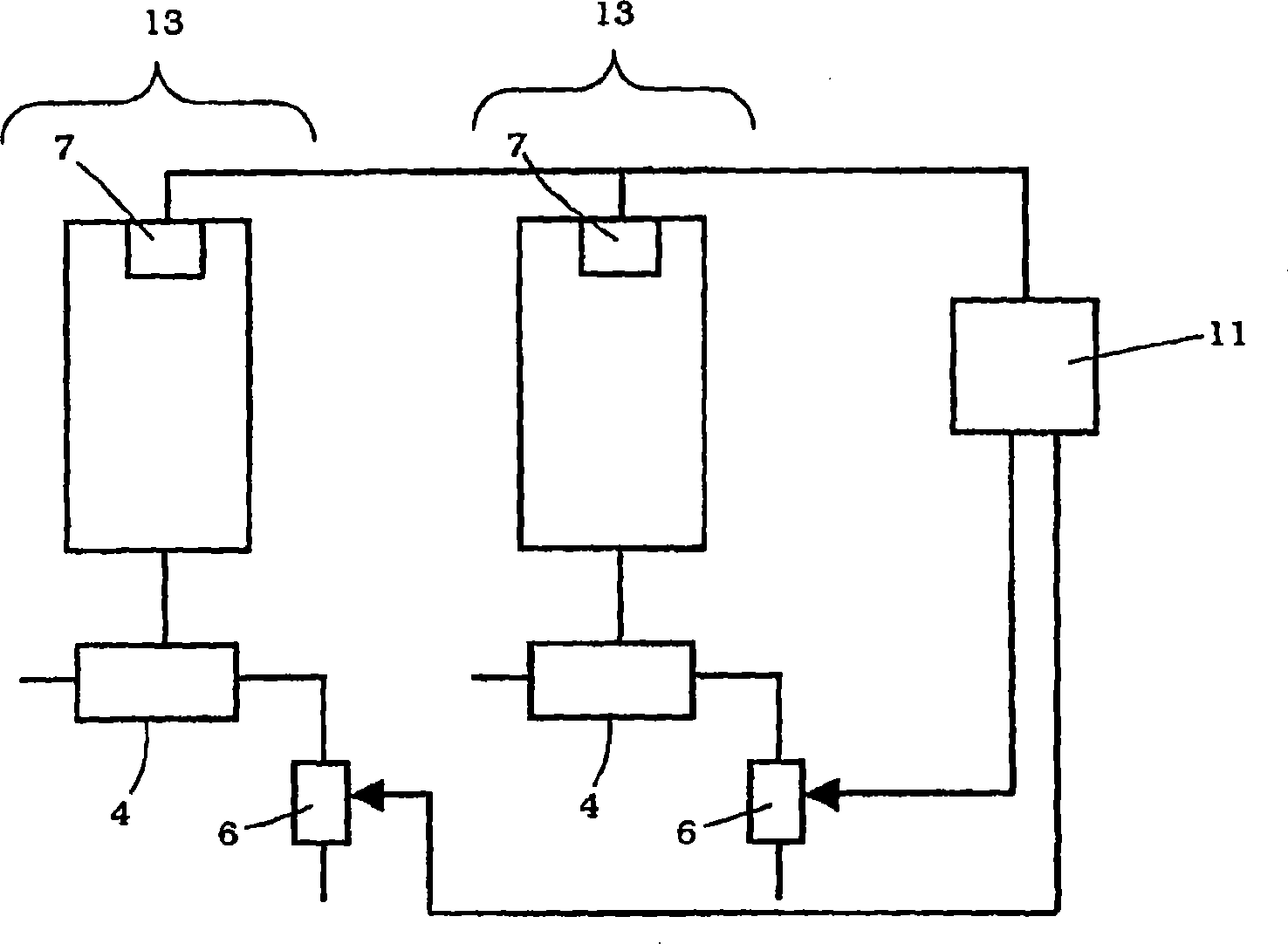

[0043] As described above, the present invention relates to a ground compacting device designed as a vibratory compacting plate, the constructional concept of which is known in principle. The basic building block of a vibratory compaction plate is a vibration exciter device, which introduces a directional vibration into a ground-contacting plate. The vibrating ground contact plate acts into the ground to compact it. In addition, the resultant total force generated by the vibration exciter means enables a longitudinal or transverse forward movement and an actuation of the vibratory tamper plate. Since this structural concept has been known in principle for a long time, a more detailed description is superfluous.

[0044] The vibratory tamper plate according to the invention has a vibration exciter arrangement with at least two individual exciters 13 which act on a ground contact plate 12 .

[0045] figure 1 A sectional view showing a schematic constructional solution of a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com