Optimizing allocation quick fix general-purpose door pocket as well as manufacturing method thereof

A manufacturing method and door cover technology, which is applied in the direction of window/door frame, etc., can solve the problems of large motherboard specifications, poor integrity, and incompatibility, and achieve the effects of reduced connection workload, short installation time, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

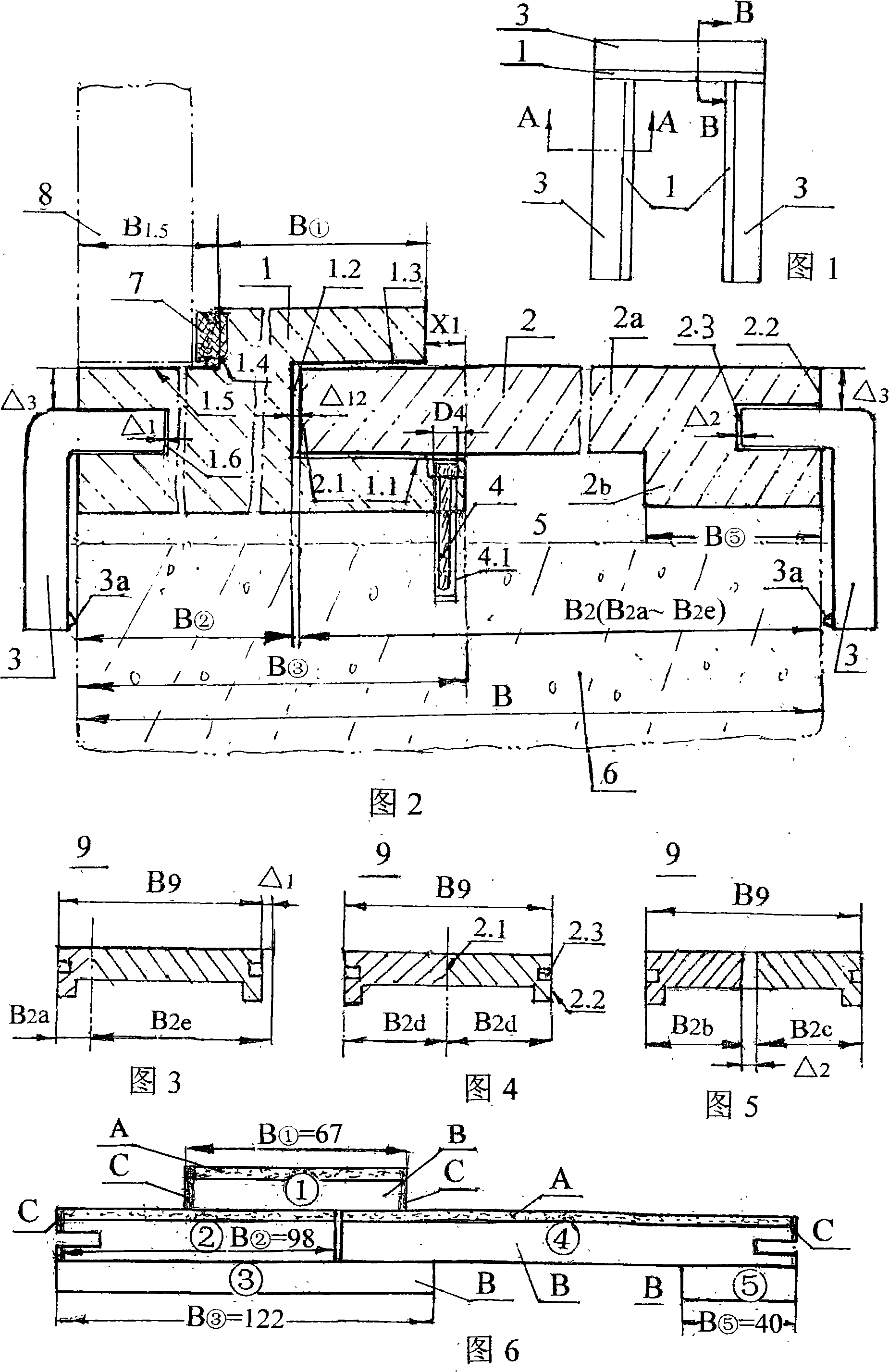

[0018] As shown in Figure 1, the optimized and quick-installed universal door pocket is composed of two side door pockets and a top door pocket, and the specific structure of the door pockets is the same. The specific structure of the door cover of each section is as follows:

[0019] As shown in Figure 2, the main board 1 is a whole board; one end has a 匚-shaped groove 1.2, and the inner edge 1.1 of the 匚-shaped groove is longer than the outer edge 13 by X 1 . at length X 1 Four connectors 4 are established from top to bottom along the door height direction to fix the main board on the wall 6, and the connectors 4 can adopt iron nails, wood screws or self-tapping screws. Rectangular gap 1.5 is opened on the main board 1 at 8 places of the door leaf. Have a groove 1.6 on the end face of the main board at the door, and a decorative L-shaped plate 3 is inserted in it. One end 2.1 of the auxiliary plate 2 is inserted into the 匚-shaped groove, and the other end 2.2 is thickene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com