Method for multi-load photoelectric tracking equipment self-adjusting two light axes to be parallel

A photoelectric tracking, optical axis parallel technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of being unsuitable for mass production, difficult to maintain in the field, troublesome for manual adjustment, etc., to achieve easy field maintenance, save labor and time, and ensure high The effect of precision

Inactive Publication Date: 2008-10-29

CHANGCHUN UP OPTOTECH

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, in the high-precision photoelectric automatic tracking and measuring equipment, it was not enough to ensure the parallelism of the two optical axes only by the base surface at the time of design, and it could only be adjusted manually. It is guaranteed by equipment such as collimator, and it is very labor-intensive to adjust. It needs to be tested bit by bit. At present, this method is not suitable for mass production, and the maintenance in the field is also very difficult, and it needs professionals to adjust.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

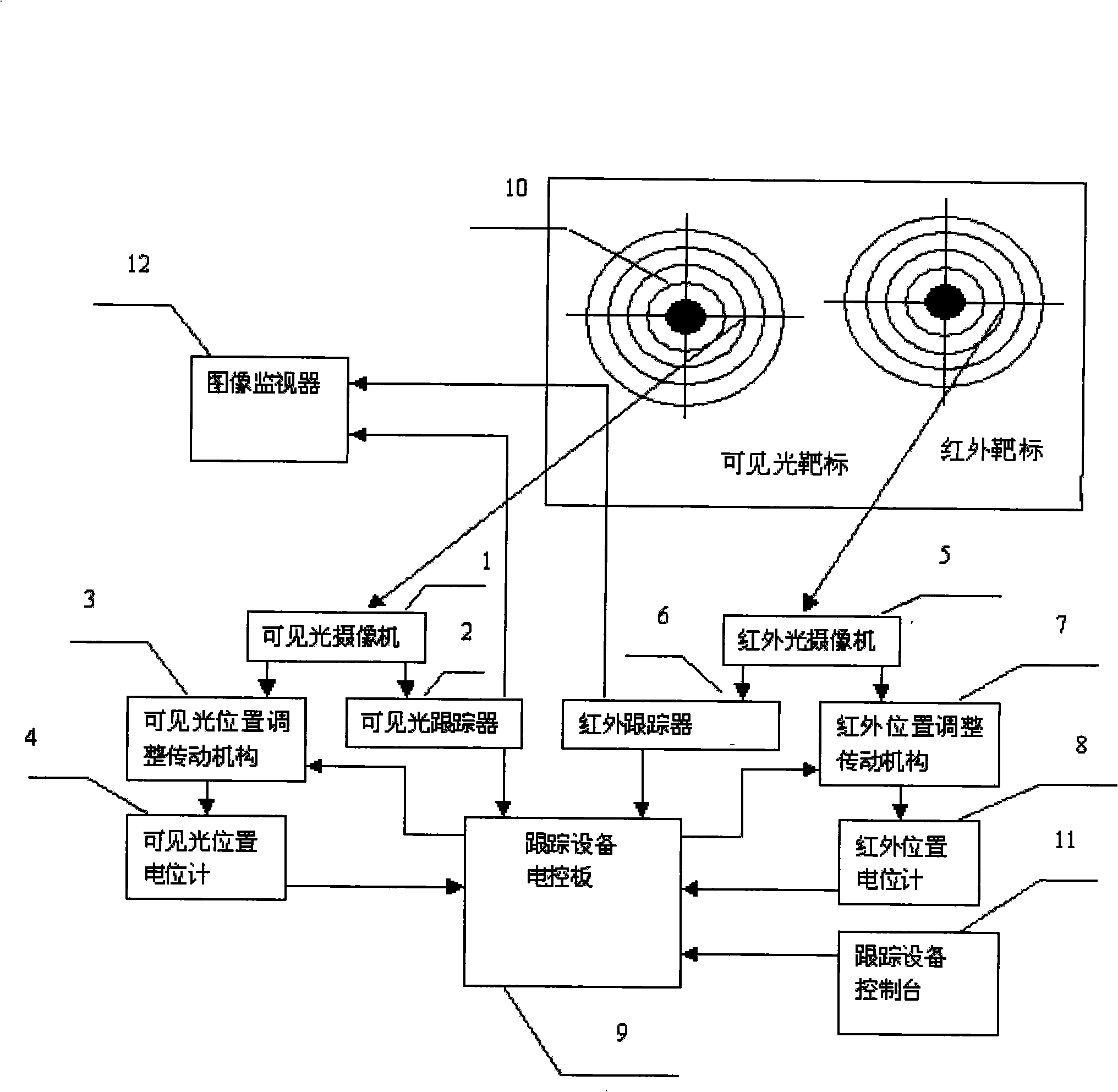

[0017] The present invention can realize the adjustment of the parallelism of the two optical axes of the multi-load photoelectric tracking device by using the target and the image monitor according to each sub-system of the start-up device itself as shown in Fig. 1 and operating according to adjustment methods 1-5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method for realizing automatic self-adjustment of the parallelism of the two optical axes of a multiload photoelectric tracing device belongs to the technology field of photoelectric tracing measurement and relates to a method for adjusting the parallelism of the two optical axes. The technical problem to be solved is to provide a method for realizing automatic self-adjustment of the parallelism of the two optical axes of the multiload photoelectric tracing device. The technical proposal is that the self-subsystem of a device to be adjusted is started; a visible light camera and a noctovisor are respectively connected with a tracing device frame by a transmission gear; the target centers of a drone are traced by a television tracer; the undershooting amount is taken as the position feedback amount of the transmission gear; a potentiometer is taken a position sensor; the transmission gear automatically adjusts the orientation and the pitching direction of the cameras until the two target centers of the drone are aligned with the centers of field coverage of the two cameras; the undershooting amount of the target centers is taken as the position feedback of the optical axes, and the optical axes are automatically adjusted by the transmission gear, which is the key of the method. The method is simple, without the need of additional devices; and the outfield maintenance is easy.

Description

Technical field: [0001] The invention belongs to the technical field of photoelectric tracking measurement, and relates to a method for automatically adjusting the parallelism of two optical axes of a photoelectric tracking device itself. Background technique: [0002] In the multi-load photoelectric automatic tracking measurement equipment, if the photoelectric tracking measurement equipment has a visible light camera and an infrared camera at the same time, it is necessary to adjust the two optical axes to make them strictly parallel, which is very important to ensure the tracking measurement accuracy. In the past, in the high-precision photoelectric automatic tracking and measuring equipment, it was not enough to ensure the parallelism of the two optical axes only by the base surface at the time of design, and it could only be adjusted manually. It is guaranteed by equipment such as collimator, and the adjustment is very labor-intensive, and it needs to be tested bit by b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01C25/00

Inventor 宋建中戴明刘晶红

Owner CHANGCHUN UP OPTOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com