Servo press mounting device for monitoring press mounting force and displacement

A press-fitting force and press-fitting machine technology, applied in the field of servo press-fitting machines for monitoring press-fitting force and displacement, can solve problems such as difficult adjustment, inability to detect changes in press-fitting force, difficult pressure control, etc., and achieve precise, convenient and qualified control The judgment method is scientific and diverse, and the speed is stable and adjustable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

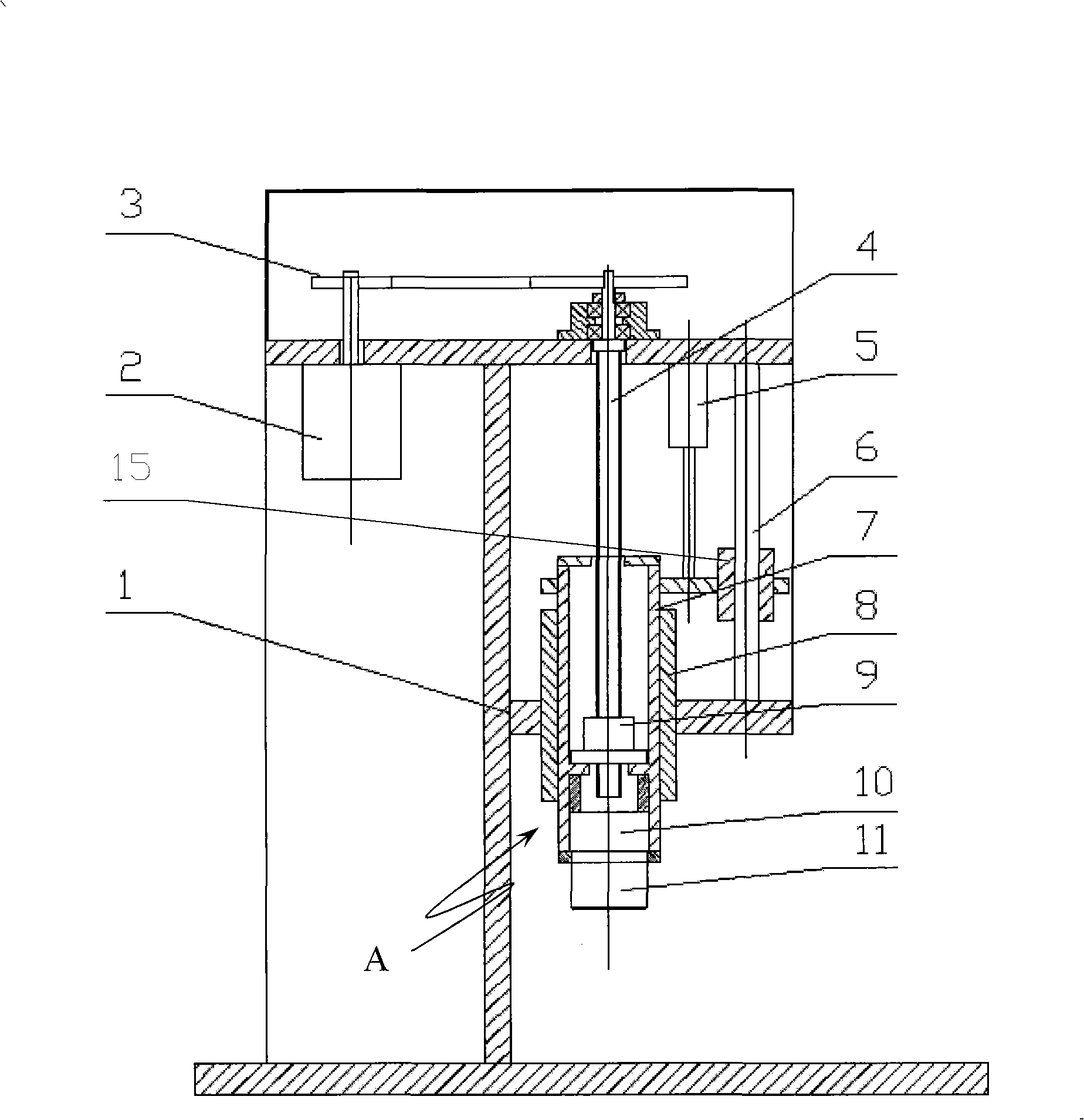

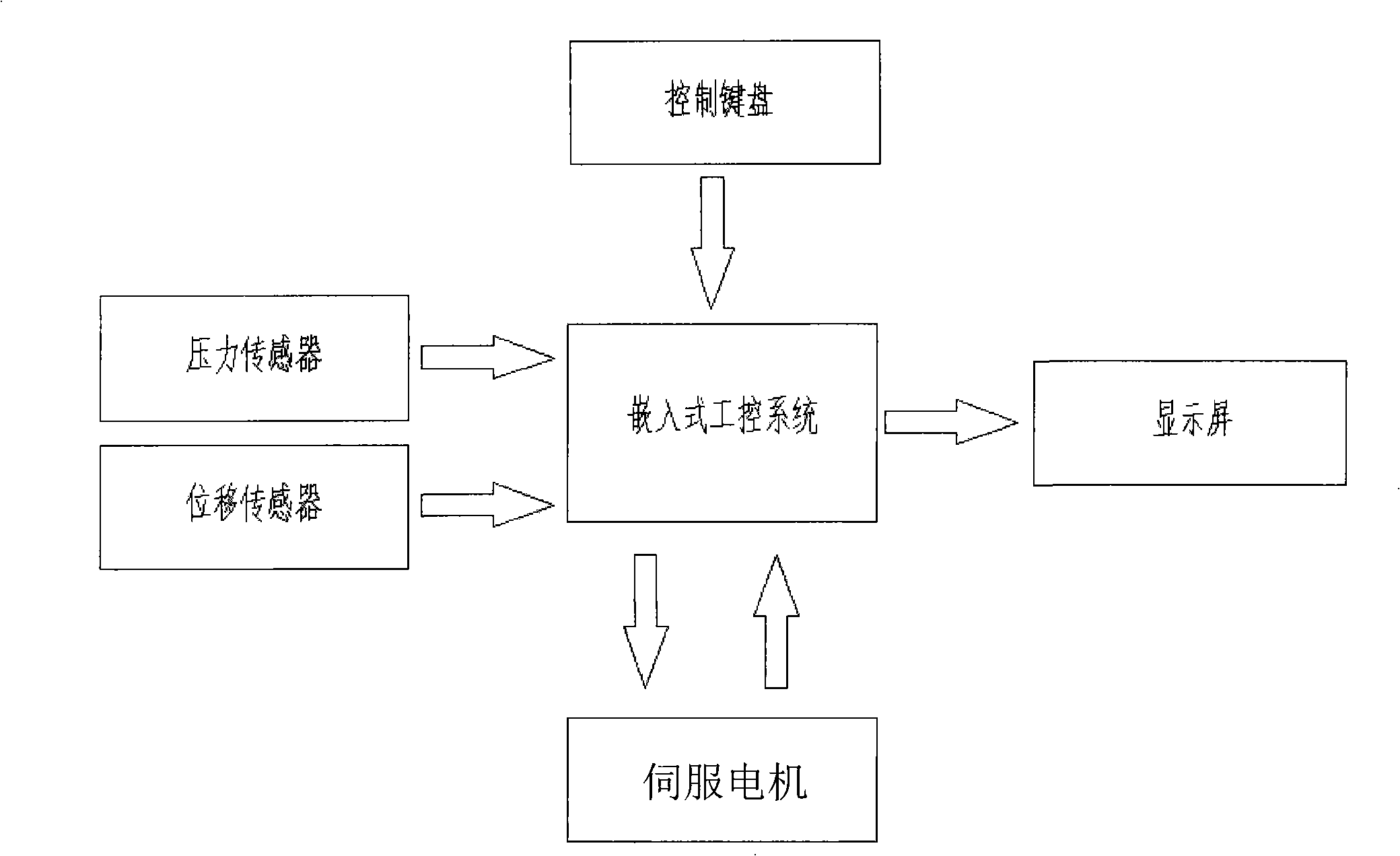

[0022] Such as figure 1 The shown servo press-fitting machine for monitoring the press-fitting force and displacement has a basic structure including a frame 1, a drive device installed on the frame 1, and a press-fitting head A which is driven by the drive device and moves on the frame 1: power device It includes the servo motor 2 controlled by the embedded industrial control system and the drive part 4 that is driven and coordinated with the servo motor 2. The drive part 4 is threadedly matched with the press-fitting head A; The pressure sensor 10 is connected with a displacement sensor 5, and the embedded industrial control system is connected with a display and a control keyboard.

[0023] More specifically:

[0024] The press-fitting head A includes a press head 11 and a displacement member 7, and the press head 11 is assembled on the displacement member 7. In order to make the displacement member 7 and the driving member 4 fit through threads, the press-fit head A also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com